Overspeed protection mechanism for assisting ladder

A technology for overspeed protection and booster lifts, applied in elevators, transportation and packaging, etc., can solve problems such as potential safety hazards, and achieve the effects of long service life, simple structure, and convenient manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

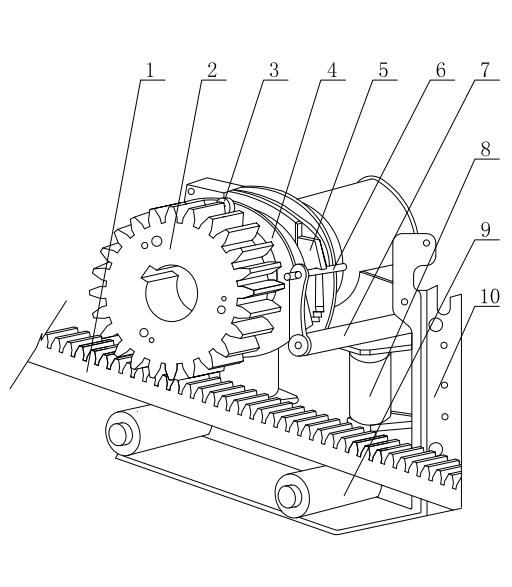

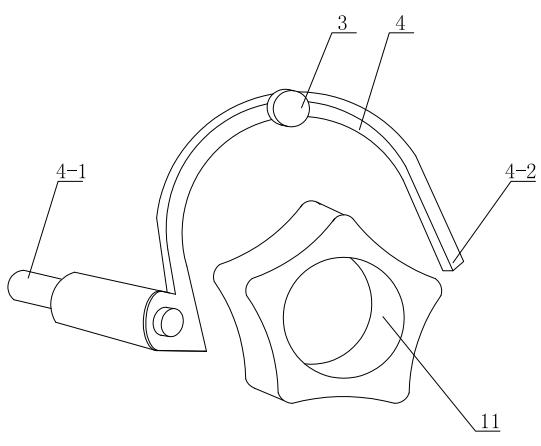

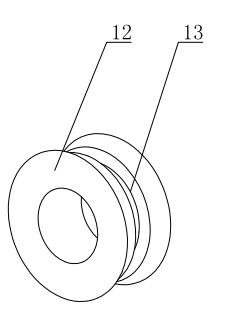

[0018] Such as figure 1 As shown, the booster elevator overspeed protection mechanism of the present invention includes a frame 10, and a transmission mechanism that drives along the guide rail is installed on the frame 10. The transmission mechanism is a rack and pinion mechanism, and the rack 1 is welded to the first guide rail. Above (not shown in the figure), the first guide rail is located above a pair of rollers 9; the gear 2 meshed with the rack 1 is installed on the shaft; see figure 2 A pentagonal bump 11 is also installed on the rotating shaft coaxial with the gear 2, and a semicircular swing arm 4 cooperating with it is provided on the outer circumference of the pentagon bump 11, and one end of the swing arm 4 passes through the pin shaft 4 -1 is hinged with the frame 10, the other end of the swing arm 4 is provided with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com