Formation testing while drilling instrument

A tester and formation technology, applied in the field of formation tester while drilling, can solve the problems of inconvenient maintenance and other problems, and achieve the effects of reducing occupied time, improving convenience and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

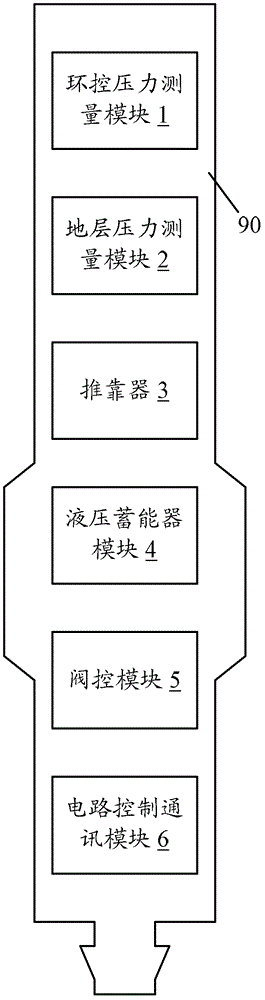

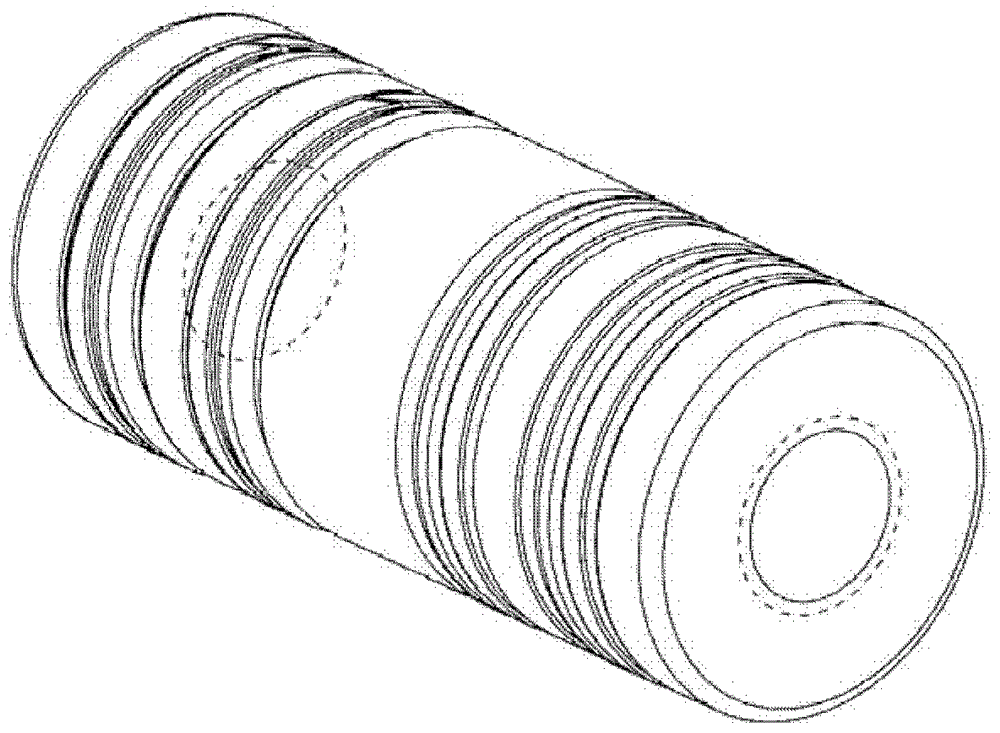

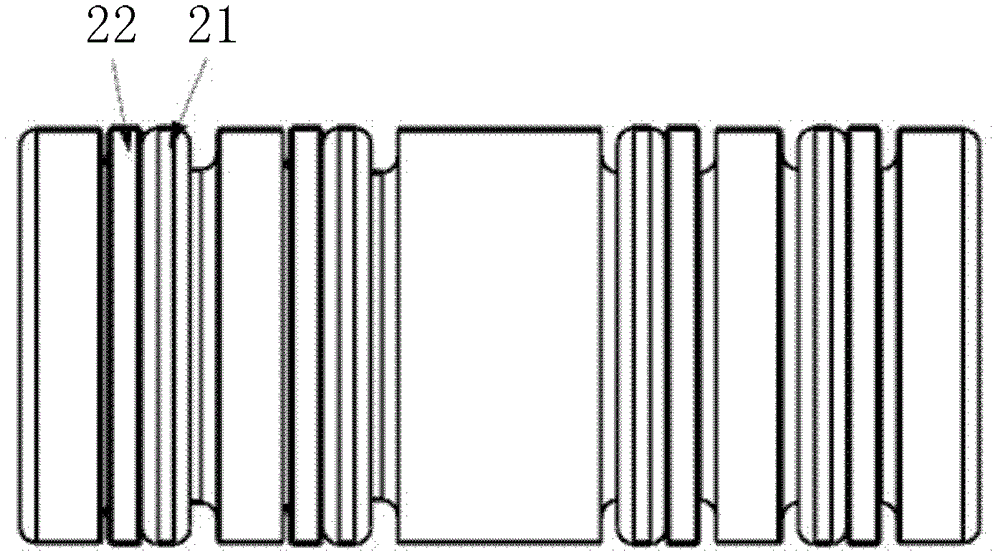

[0029] like figure 1 As shown, the formation tester while drilling in the embodiment of the present invention is embedded in the drill collar matrix 90, and mainly includes an environmental control pressure measurement module 1, a formation pressure measurement module 2, a pusher 3, a hydraulic accumulator module 4, a valve Control module 5 and circuit control communication module 6.

[0030] The environmental control pressure measurement module 1 contains a pressure sensor, which is used to measure the pressure of the mud in the drilling wellbore, and transmits the pressure value of the mud to the circuit control communication module 6 in real time, providing a basis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com