Multi-cylinder synchronous structure of hydraulic system

A technology of hydraulic system and hydraulic cylinder, applied in the field of multi-cylinder synchronous structure of hydraulic system, can solve the problems of inconsistent friction gap, error of cylinder machining accuracy, and difficulty in controlling the parallelism of sliders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

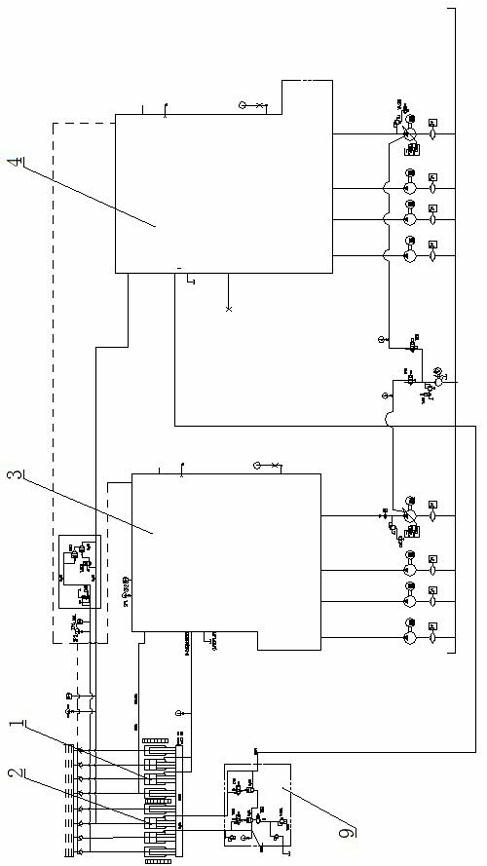

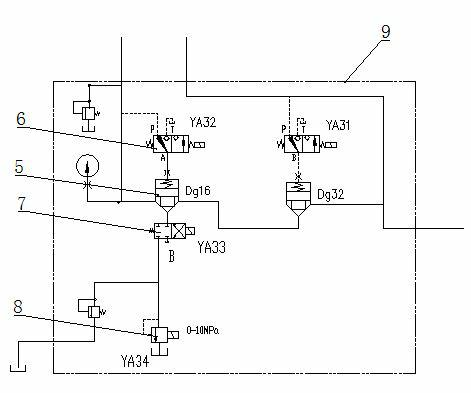

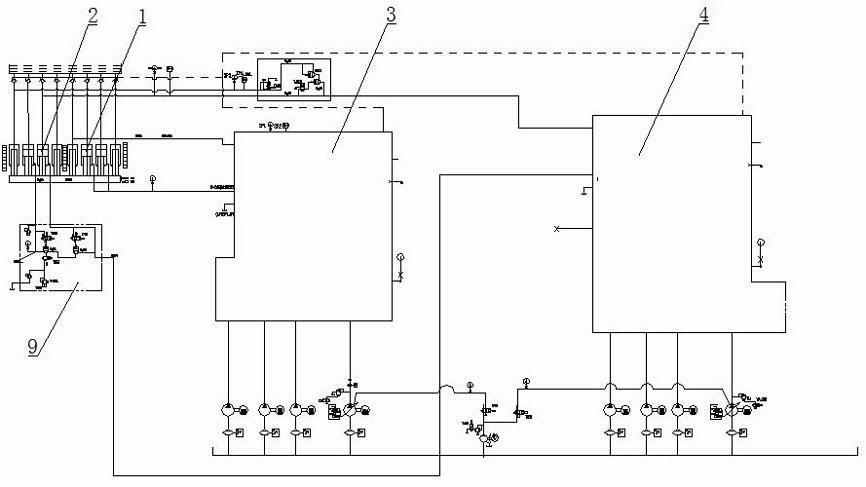

[0009] Such as figure 1 , 2 As shown, hydraulic cylinder group Ⅰ1, hydraulic cylinder group Ⅱ2, system Ⅰ3, system Ⅱ4, plug-in 5, solenoid ball valve A6, two-position four-way solenoid valve B7, proportional pressure regulating valve 8.

[0010] The hydraulic cylinder group I1 and the hydraulic cylinder group II2 are supplied with fluid by the system I3 and the system II4 respectively.

[0011] A device for controlling the oil discharge volume of the return chamber of the hydraulic cylinder group II2 is provided on the return chamber of the hydraulic cylinder group II2 based on the pressure of the return chamber of the hydraulic cylinder group I1.

[0012] The return cavity oil discharge control device 9 includes a plug-in 5, a solenoid ball valve A6, a two-position four-way solenoid valve B7 and a proportional pressure regulating valve 8, wherein the plug-in 5 has three oil ports a, b, and c, and when the c oil port When there is pressure, port a and port b are disconnected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com