a foam gun

A foaming gun and foaming agent technology, applied in the engineering field, can solve the problems of high processing precision, high production cost, and many parts and components, and achieve the effects of convenient processing, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

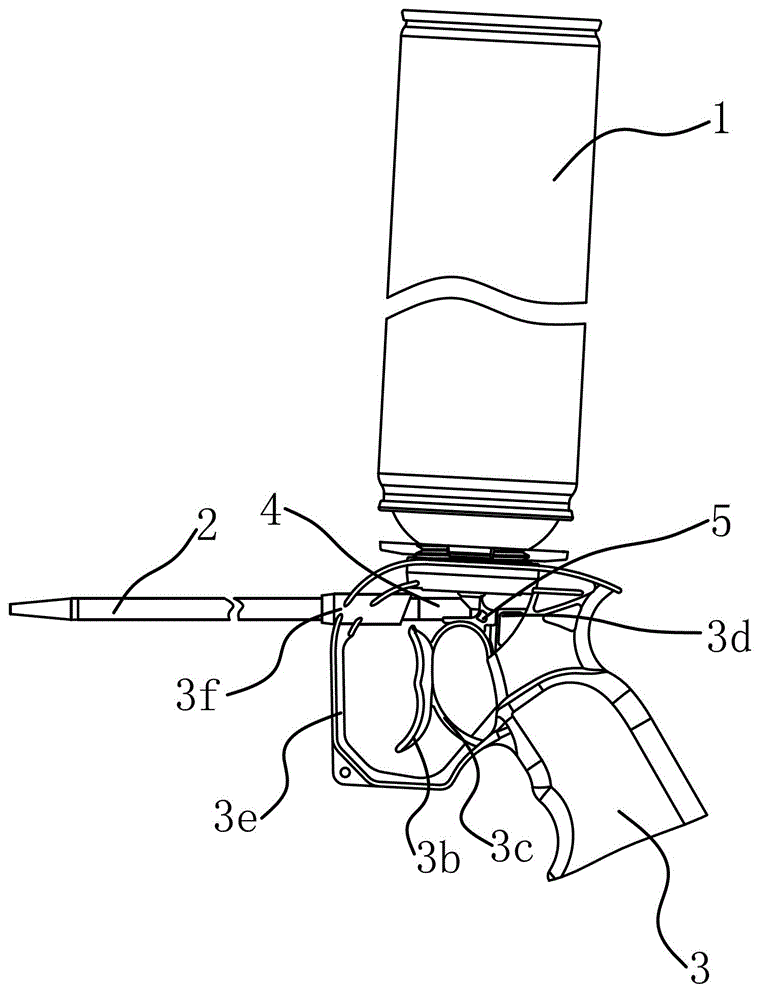

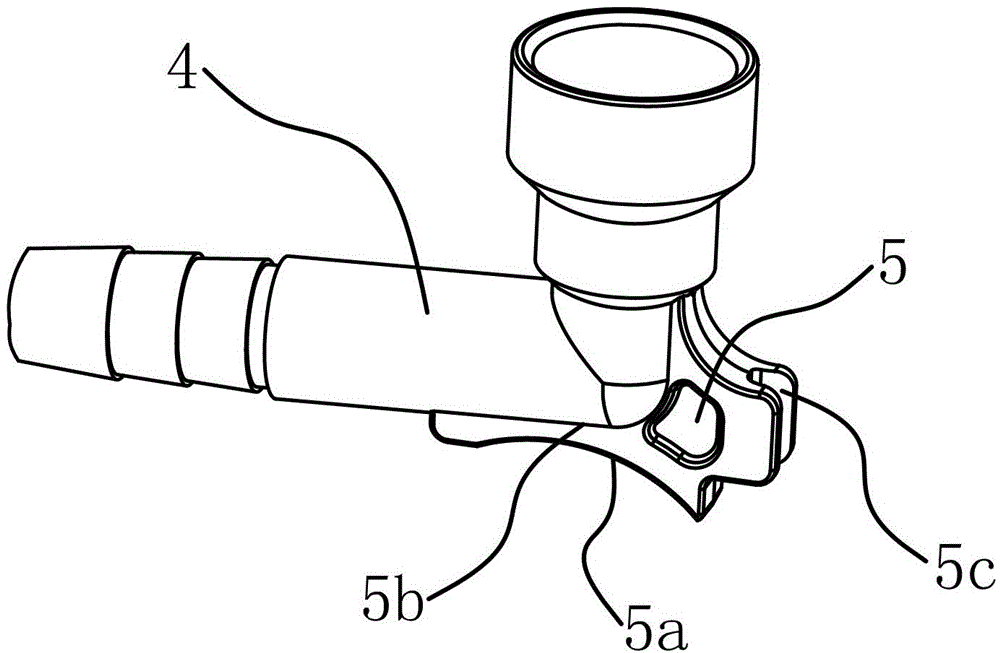

[0030] The foaming gun is used to open the spray nozzle of the foaming agent pressure tank to achieve the purpose of filling gaps with the polyurethane foaming agent. The foaming agent pressure tank is an existing material and can be purchased in the construction hardware market. Such as figure 1 Shown, this foaming gun comprises spray pipe 2 and gun handle 3. The gun handle 3 is a part for the operator to hold. Its inside is a cavity, and the inner wall of the cavity has reinforcing ribs. This structure saves materials, is low in cost, and light in weight, while ensuring the firmness of the gun handle 3 .

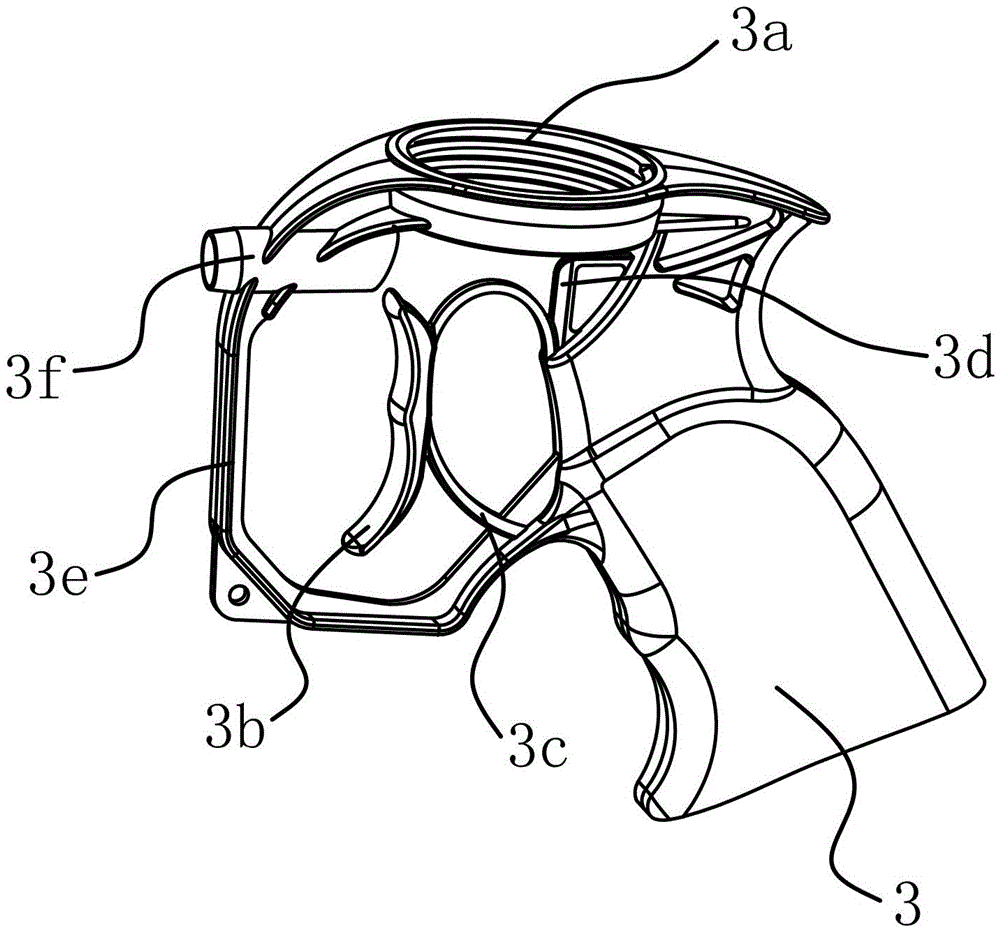

[0031] Such as figure 1 , figure 2 As shown, the top of the gun handle 3 has a connecting portion 3a that is fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com