Floor cleaning heads for surface cleaning equipment

A floor cleaning and surface cleaning technology, applied in the direction of machine parts, suction nozzles, etc., can solve the problem of not improving the suction efficiency, water and detergent consumption, being opened or both are closed, and the two scrapers rotate inconsistently before and after, etc. problems, to achieve the effect of reducing the frequency of cleaning or replacing cleaning tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

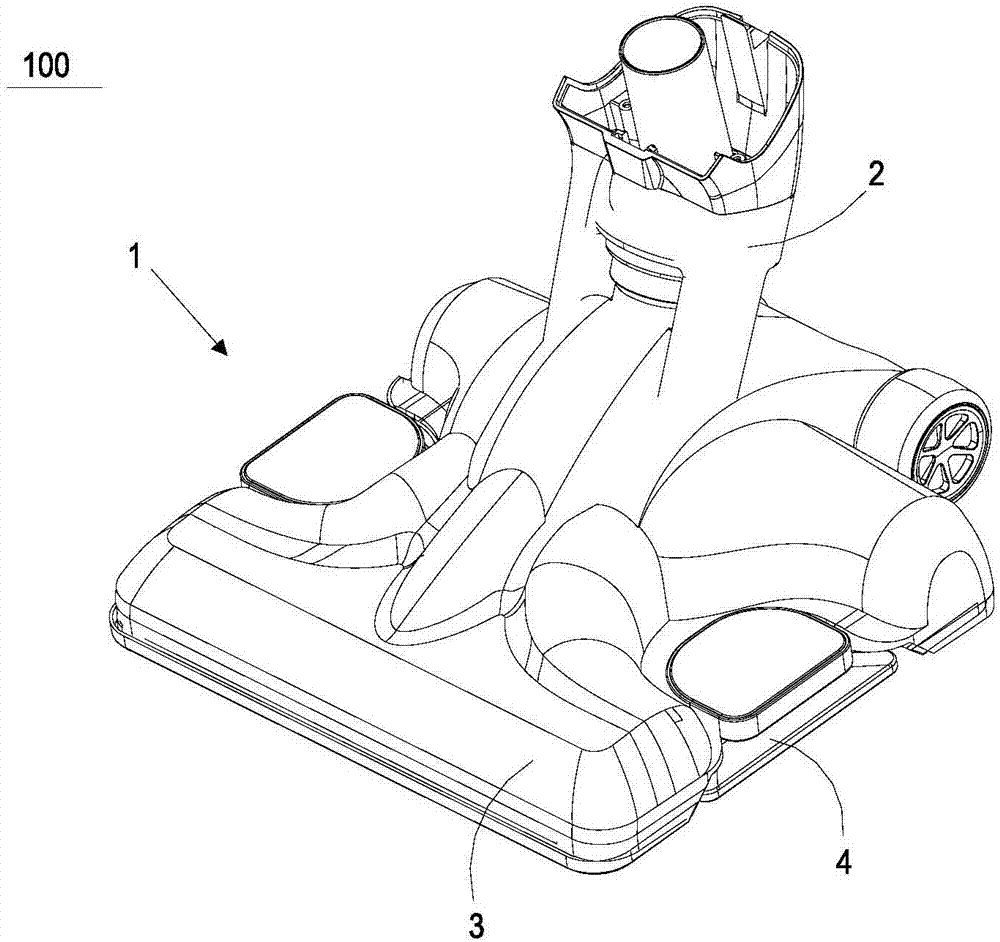

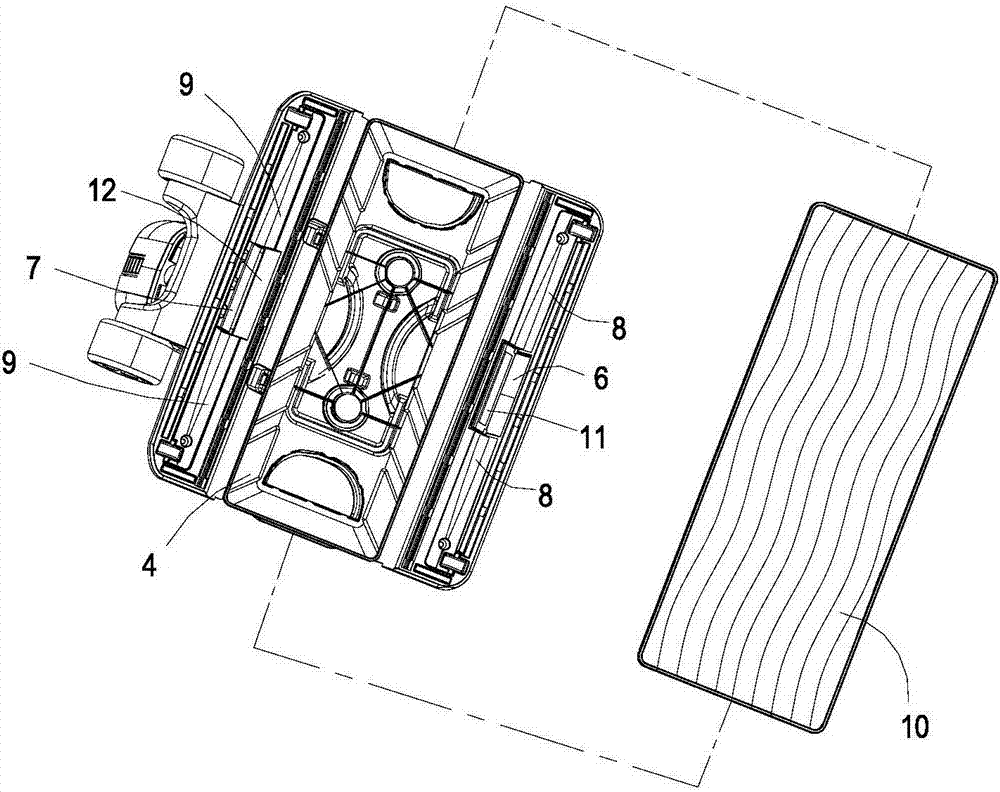

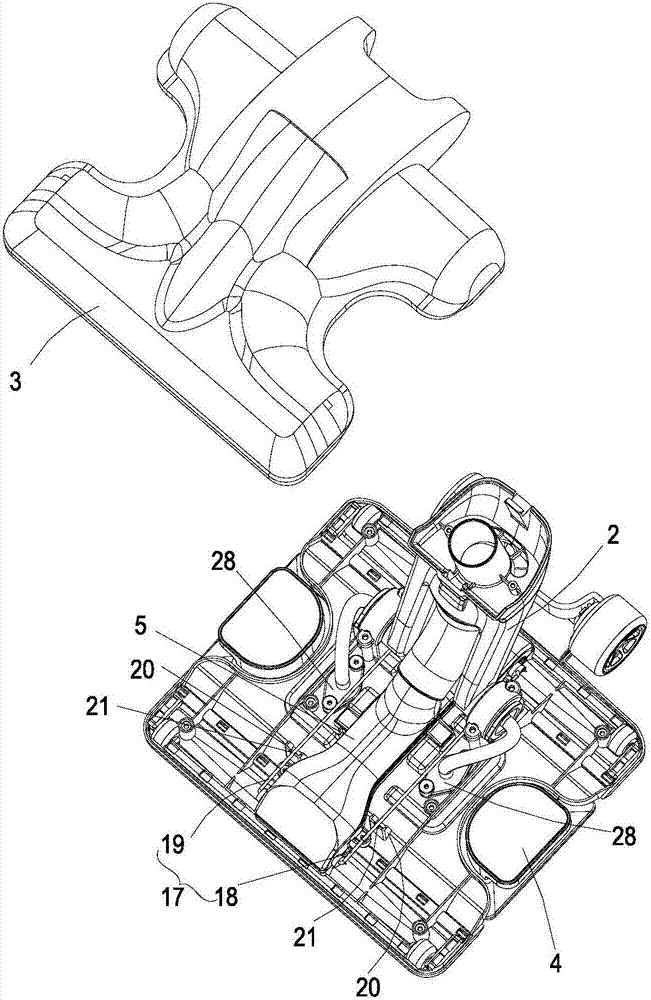

[0042] like figure 1 Shown is a floor cleaning head 100 for a steam mop, the floor cleaning head 100 is adapted to move back and forth over the floor to be cleaned. The floor cleaning head 100 has a cleaning head body 1, and the rear portion of the cleaning head body 1 is provided with a rotating joint 2, which is used to be connected with an upright handle assembly (not shown in the figure) of a steam mop, standing upright The handle assembly is configured to push the cleaning head body 1 forward and backward. The cleaning head body 1 has a first casing 3 and a second casing 4 arranged up and down, and the first casing 3 and the second casing 4 are fixed by mechanical fasteners or fastened. In this example, the rotary joint 2 is installed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com