Transfer case of large tractor

A transfer case and tractor technology, which is applied to mechanical equipment, transmission devices, gear transmission devices, etc., can solve problems such as difficulty in meeting the development needs of high-power tractors, and achieve the effects of reasonable speed ratio matching, convenient operation, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

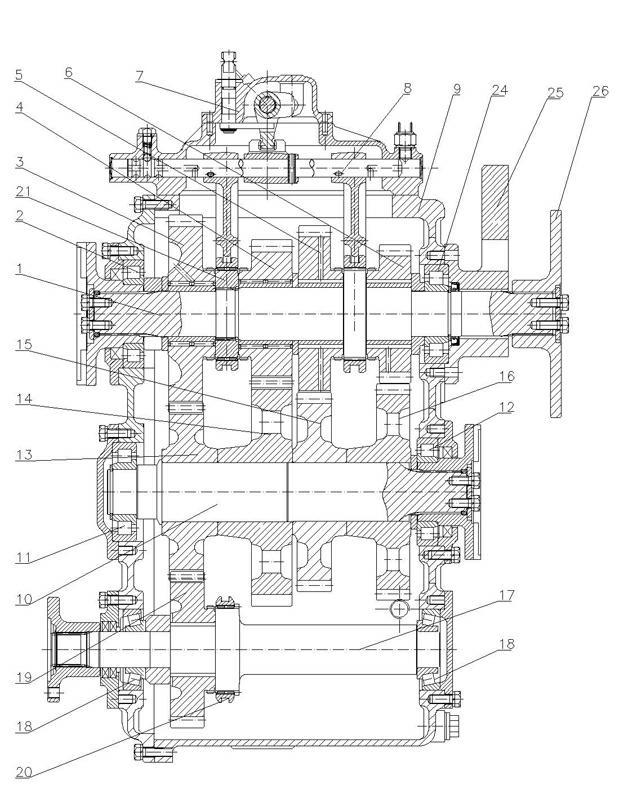

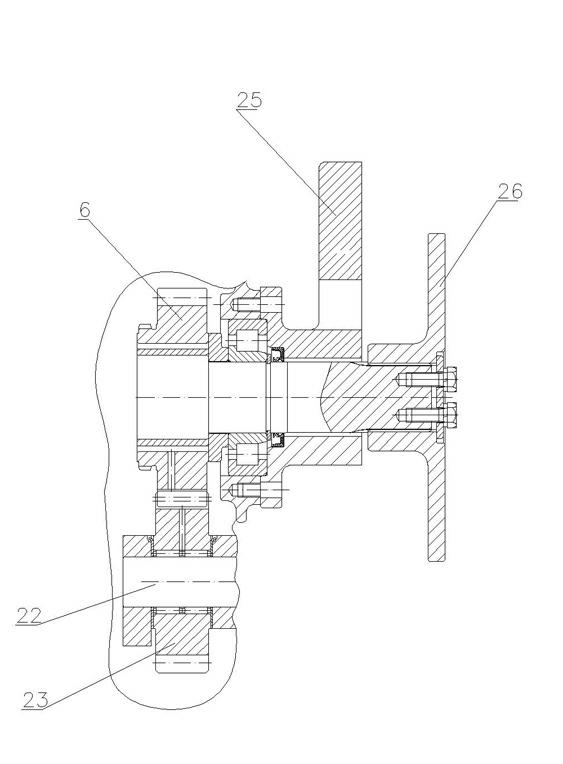

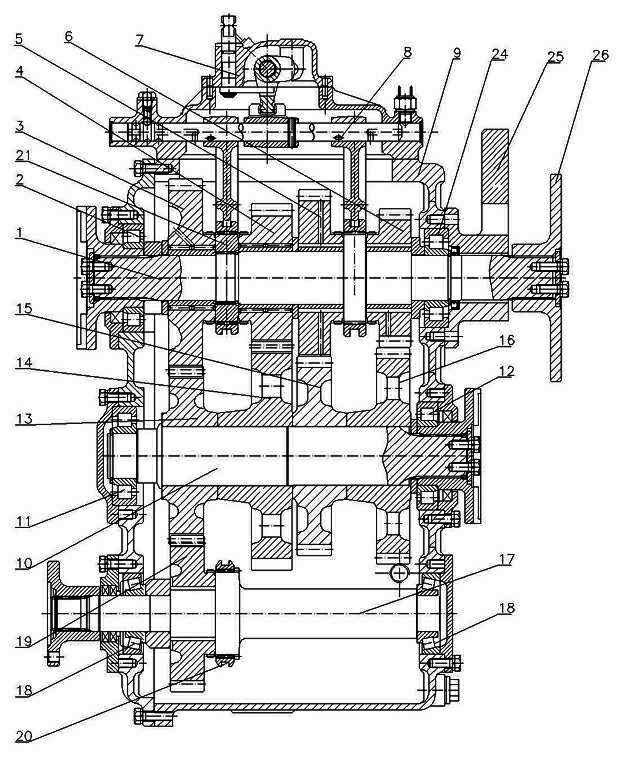

[0015] Such as figure 1 , figure 2 As shown, a large tractor transfer case of the present invention includes an input shaft 1, a rear axle output shaft 10, and a front axle output shaft 17 installed in the housing assembly 9 sequentially from top to bottom.

[0016] The input shaft 1 is supported on the housing assembly 9 through cylindrical roller bearings 2 and 24, and the high-grade input gear 3, the middle-range input gear 4, the low-range input gear 5, and the reverse gear 6 are respectively emptied on the input shaft 1 through needle bearings. Upper: High-grade input gear 3, middle-range input gear 4, low-range input gear 5, and reverse gear 6 are respectively equipped with meshing sleeve shift mechanisms, and the splines through which the high- and low-range gear holders 21 pass are fixed on the input shaft 1. Middle gear, reverse gear gear seat and input shaft 1 are made into one. The rear axle output shaft 10 is supported on the housing assembly 9 through cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com