Cooling tower silencing structure

A technology for cooling towers and mufflers, which is applied in the direction of sound-producing equipment and instruments, can solve the problems of axial flow fan wind pressure, large air volume loss, insufficient noise reduction, and high cost of noise reduction, and achieves the effect of small air volume loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

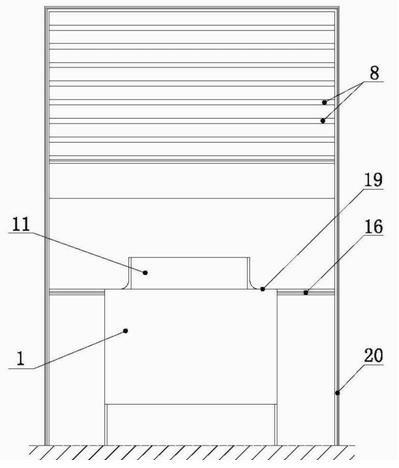

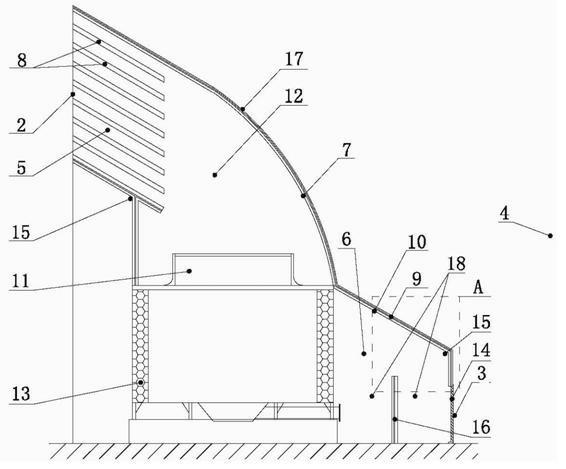

[0014] exist figure 1 Among them, the air outlet muffler (5) is on the upper part of the cooling tower (1) axial flow fan (11), and the facades (20) on both sides are on the left and right sides of the cooling tower (1), and the upper platform (19) of the cooling tower (1) There is a sound insulation layer (9) between them.

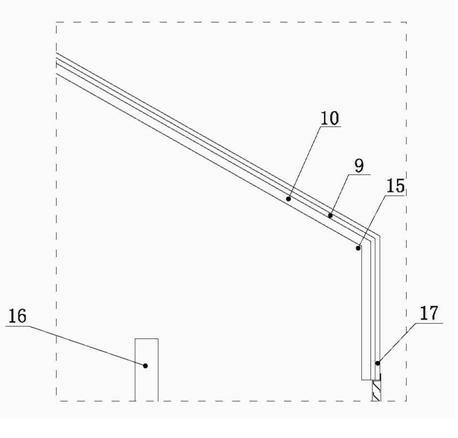

[0015] exist figure 2 , 3 In the shown embodiment, the upper and lower parts of the resistive muffler insert structure (8) of the air outlet muffler (5) are 30° oblique shape (15), and the arc-shaped flow diversion shape (7) is consistent with the axial flow Between the fan (11) is the sound-absorbing expansion area (12), the upper part of the air inlet muffler (6) is a 30° oblique shape (15), the vertical sound insulation layer (9) and the packing area (13), and the middle is the sound insulation The baffle (16), the middle of the sound insulation baffle (16) is the sound insulation layer (9), and the two sides are the sound absorption layer (10)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com