Novel oil screen

An oil net, a new type of technology, applied in the direction of oil fume removal, household heating, heating methods, etc., can solve the problems of large air loss, poor oil guiding performance of the oil net, increased noise, etc., to achieve small air loss and good filtering effect. , smooth flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

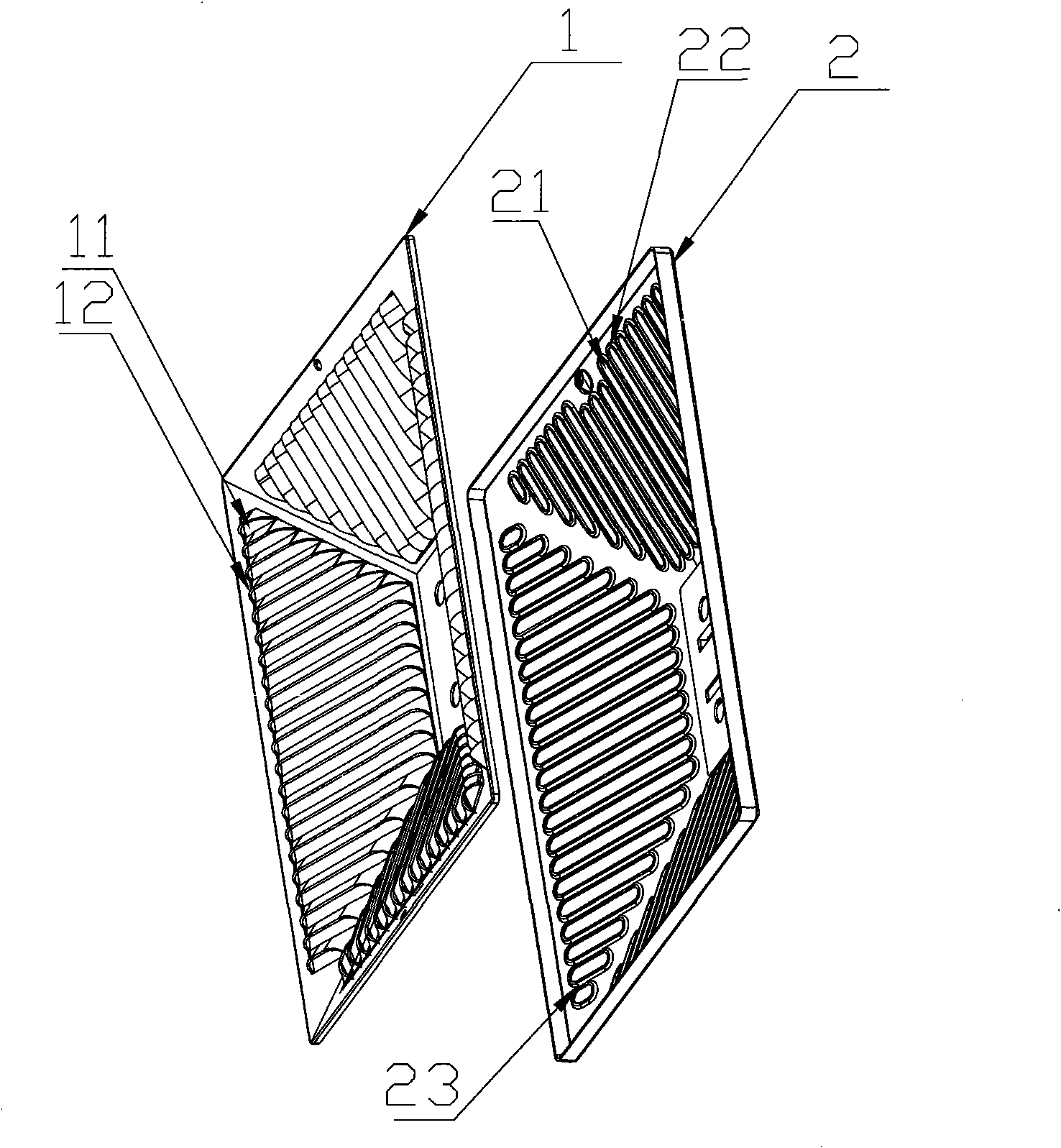

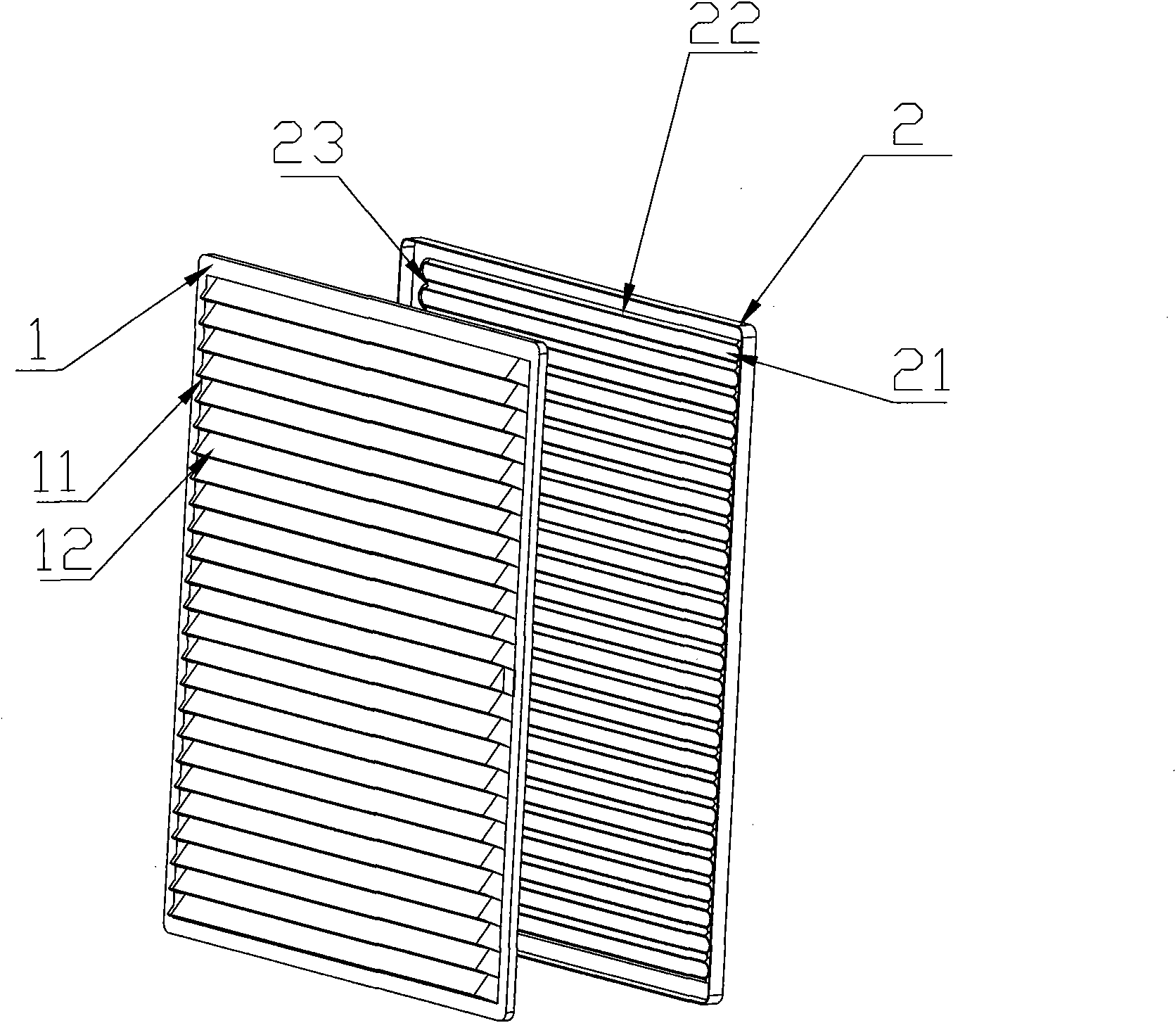

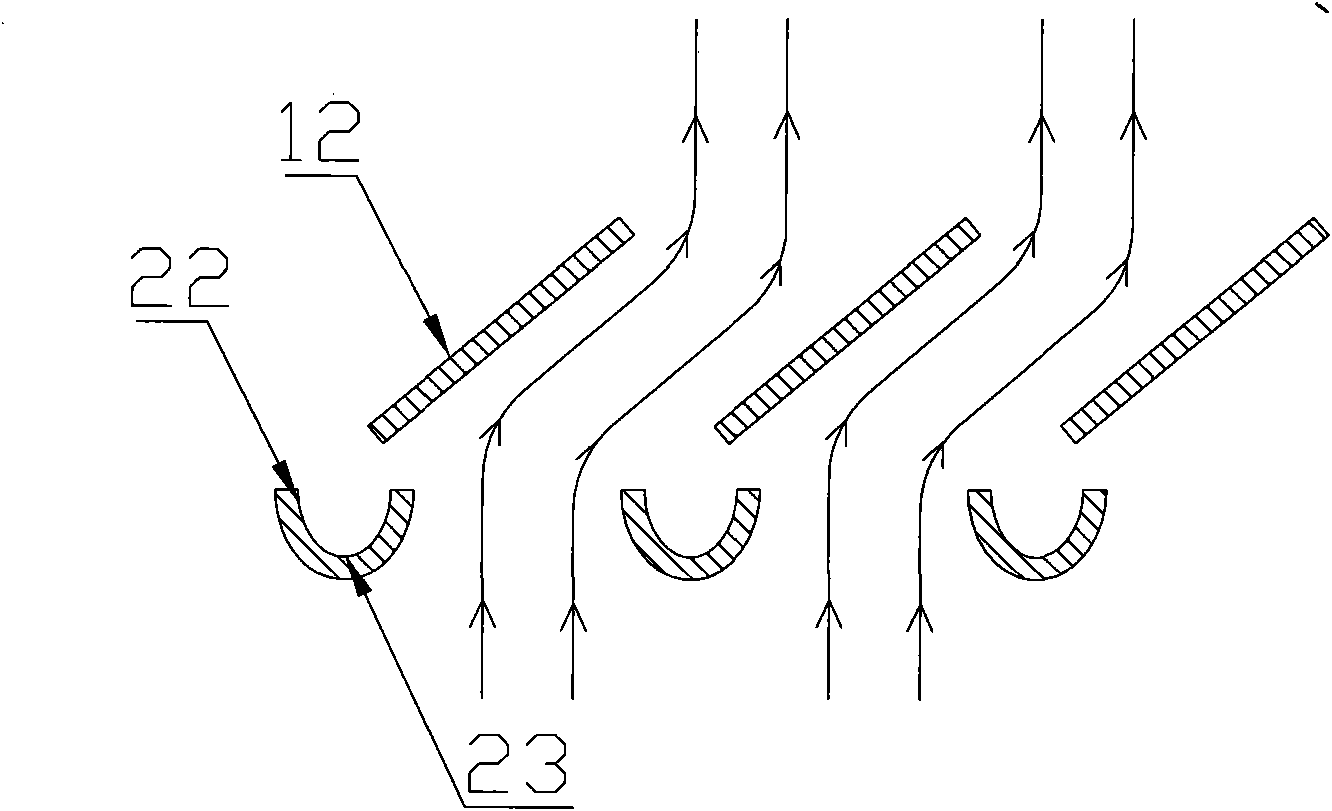

[0029] Example: A new type of oil net, including inner oil net 1 and outer oil net 2, based on the direction of use, the outer oil net 2 is located outside the inner oil net 1 (away from the inner side of the range hood), the inner and outer oil The nets 1 and 2 are respectively provided with first and second vent holes 11, 21, a side wall of the first vent hole 11 is provided with a first flange 12 at a set angle with the first vent hole 11, and the second The inner periphery of the ventilation hole 21 is provided with a second flange 22 which is closed in the direction of the inner oil net 1 and the first ventilation hole 11 and its corresponding first flange 12 completely cover the second ventilation hole 21 and its corresponding Right above the second flanging 22, the low end of the first flanging 12 is just between the two adjacent second flangings 22 corresponding to the outer oil net 2. When in use, the fume is carried along the outside by the suction of the range hood T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com