Device for large-scale true tri-axial test of original grading rockfill body and use method of method

A test device and rockfill technology are applied in the field of large-scale true triaxial test devices for original graded rockfills, which can solve the problems that test results cannot accurately and comprehensively reflect the mechanical properties of rockfills, and avoid size effects. , the effect of large axial strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

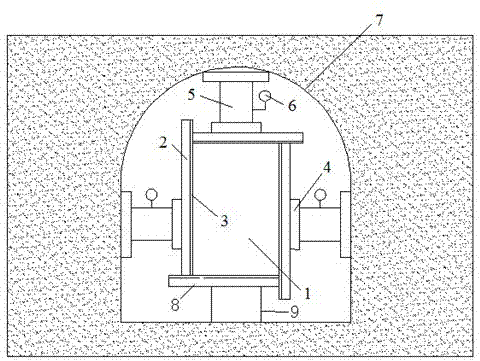

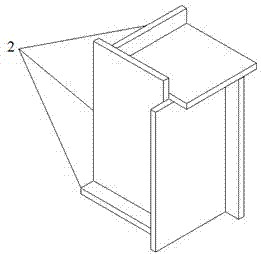

[0023] A large-scale true triaxial test device for an original graded rockfill body, including five measuring components and a fixed component set in a concrete cavern 7 for measuring the strength and deformation characteristics of a rockfill body sample 1, the measurement There are five components, namely the first measuring component, the second measuring component, the third measuring component, the fourth measuring component and the fifth measuring component, the first measuring component, the second measuring component, the third measuring component and the The four measuring components are attached to the four surfaces of the rockfill body sample 1 in turn, and the first measuring component and the second measuring component are symmetrically arranged, the third measuring component and the fourth measuring component are symmetrically arranged, and the fifth measuring component is respectively connected to the The first measuring component, the second measuring component, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com