Simulation test device and test method for bearing performance of gangue wall anchored in gob-side entry retaining

A simulation test and gangue wall technology, which is applied in the field of anchorage structure bearing performance test devices, can solve problems such as the inability to conduct underground field test tests, the inability to systematically analyze the force of the anchor rod, and the difficulty in controlling the deformation of the roadway, so as to achieve a simple and reliable test method. , Wide practicability, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

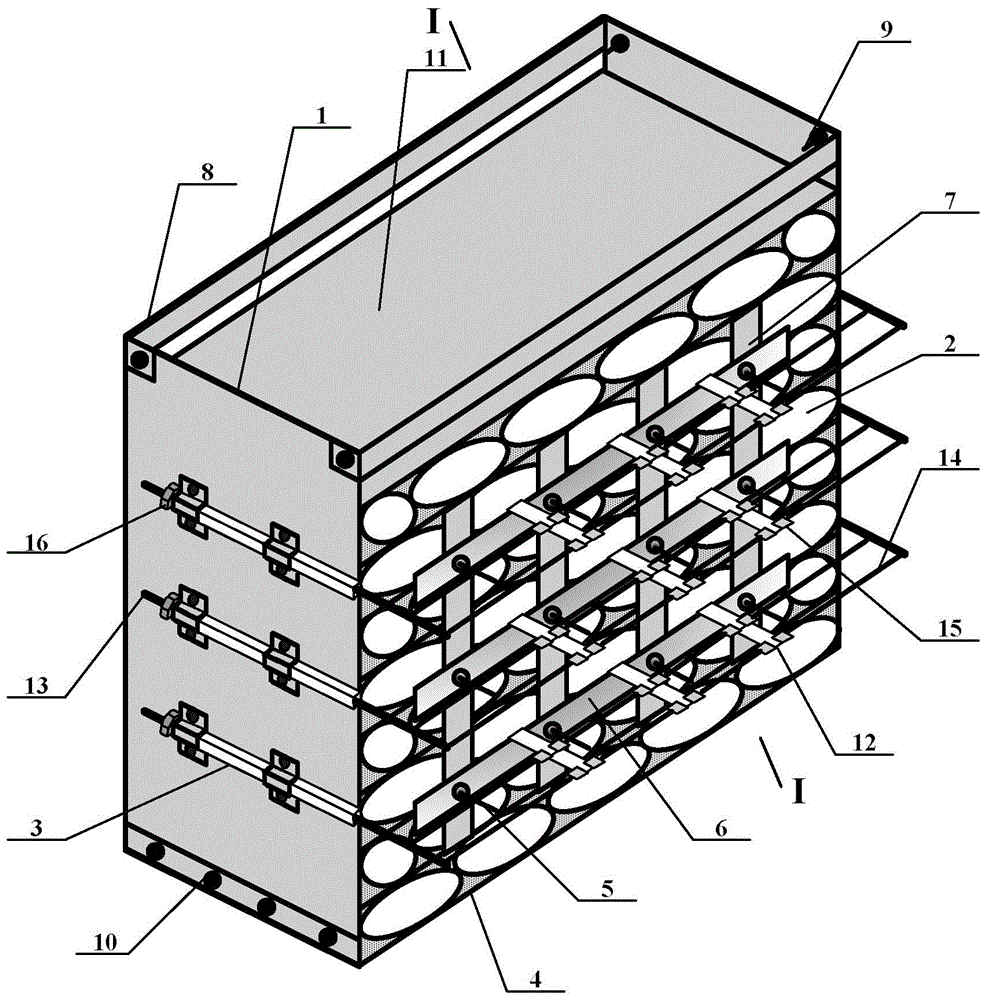

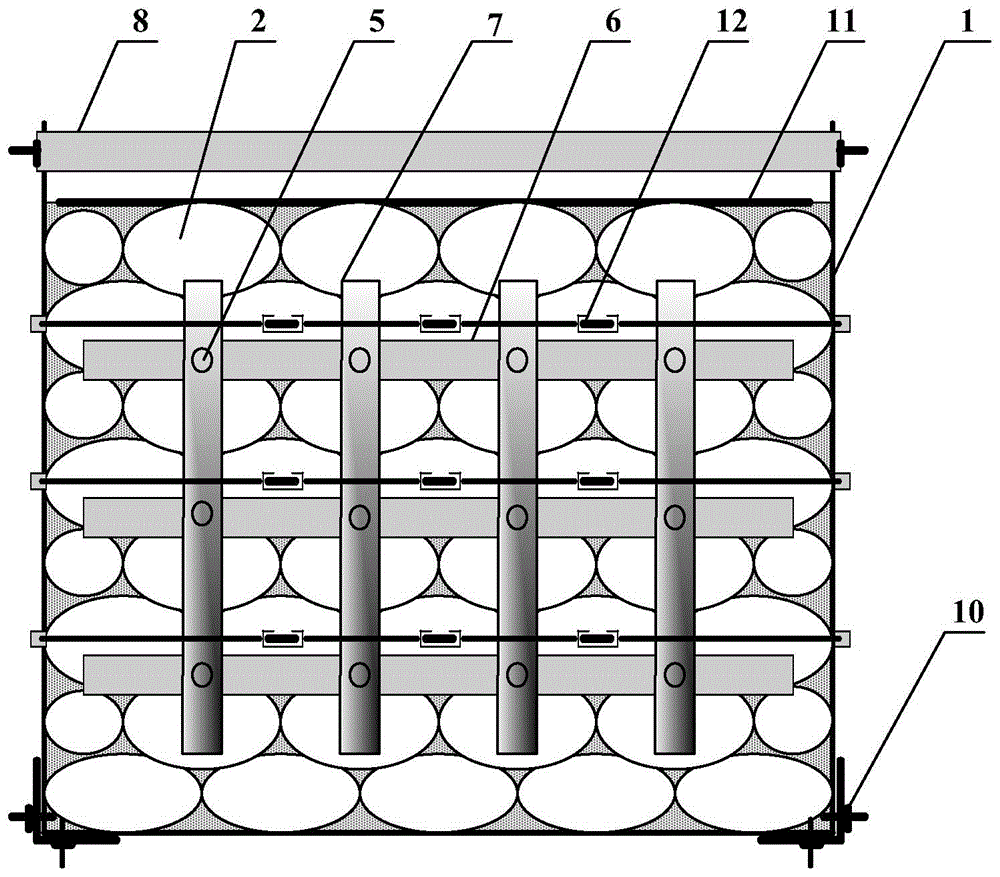

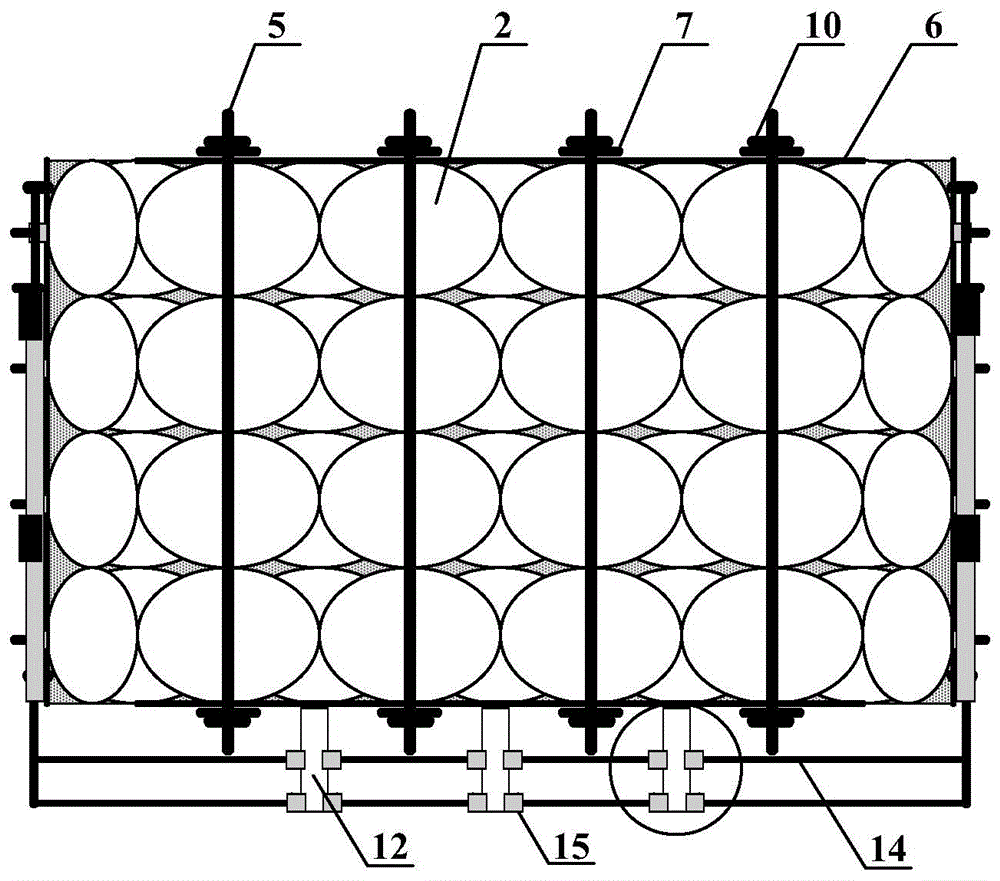

[0056] Such as figure 1 --The simulation test device for the load bearing performance of the laterally anchored gangue wall in gob-side entry retention as shown in 6. It consists of a filling groove, an anchoring filling body, a bearing plate 11 and a displacement measuring device. The anchoring filling body is placed in the filling groove, and the pressure bearing plate 11 After sinking into the filling groove, it rests on the anchor filling body, and the displacement measuring device is movably installed on the filling groove and is closely attached to the anchor filling body, wherein:

[0057] The filling tank is a U-shaped groove formed by the bottom steel plate 4 and the side steel plates 1 on both sides, and the top of the side steel plate 1 is fastened with a reinforcing steel belt 8, from figure 1 It can be seen that the reinforcing steel strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com