Tire comprising carcass reinforcement wires having different perviousnesses

A technology of crown reinforcement and reinforcement, which is applied to the reinforcement layer of pneumatic tires, heavy tires, tire parts, etc., can solve the problems of unacceptable manufacturing cost and low productivity, and achieve high productivity, beneficial cost and durability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

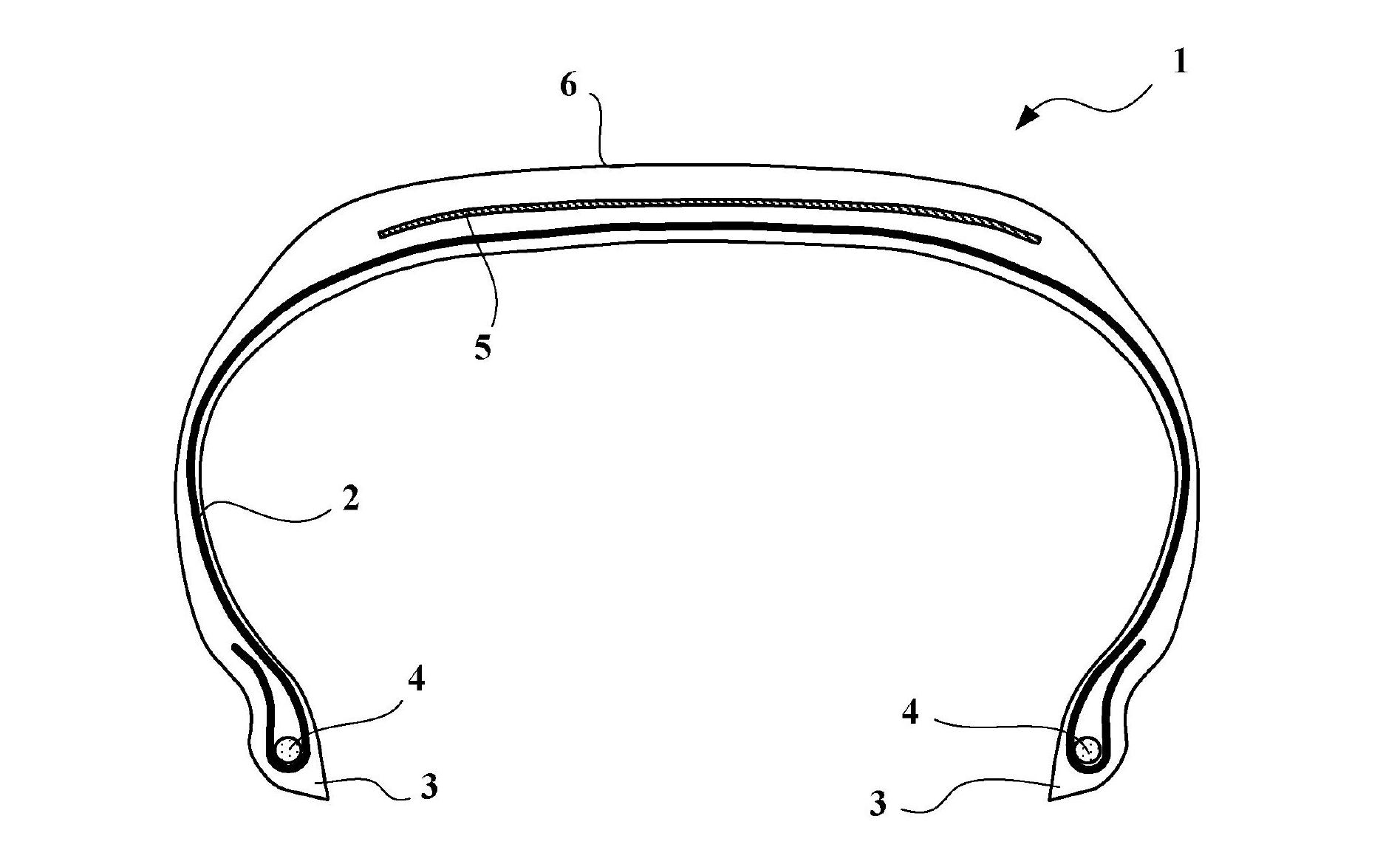

[0157] exist figure 1 , a tire 1 of size 315 / 70R 22.5 comprises a radial carcass reinforcement 2 anchored in two beads 3 around bead wires 4 . The carcass reinforcement 2 is formed of a single layer of metal cables. The carcass reinforcement 2 is hooped with a crown reinforcement 5 which itself is covered with a tread 6 . The crown reinforcement 5 is formed radially from the inside to the outside as follows:

[0158] - a first working layer formed of unwrapped non-extensible metal cables 11.35 continuous over the entire width of the ply and oriented at an angle of 18°,

[0159] - a second working layer formed by unwrapped non-extensible metal cables 11.35 continuous across the entire width of the ply, oriented at an angle of 18° and crossing the metal cables of the first working layer ,

[0160] - A protective layer formed from 6x35 elastic metal cables.

[0161] These layers constituting the crown reinforcement 5 are not all specifically shown in the drawings.

[0162]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com