Contracting rod syringe

A technology for a syringe and a retractable rod, applied in the field of medical syringes, can solve the problems of troublesome disposal, unreasonable structure, repeated use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

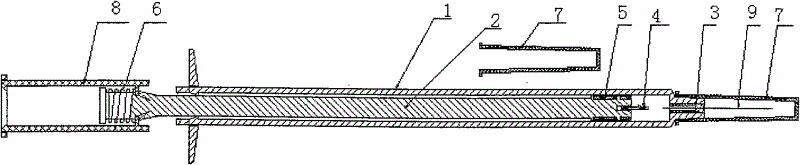

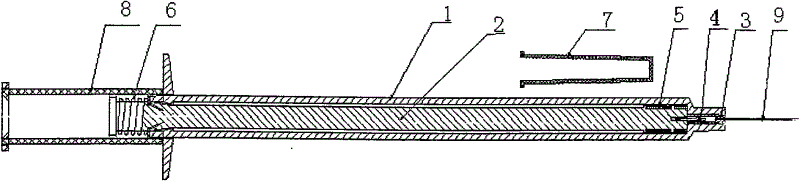

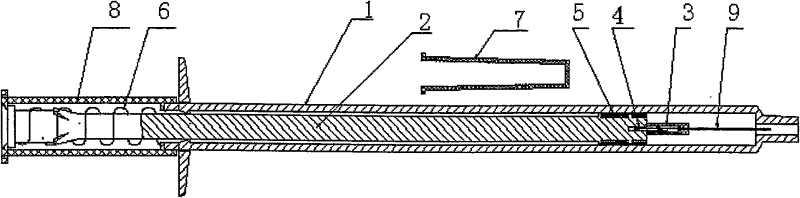

[0027] refer to figure 1 , Figure 4 The sleeve 1 of the retractable syringe syringe is basically a hollow cylinder, the opening is provided with a top ring 18 and a blocking tooth 17, and the other end of the sleeve is a protruding inner conical head 20; the top ring 18 is hollow and circular, and its inner diameter is smaller than or equal to that of the push rod The perforation 12 of the cap 8 is to ensure that the top teeth can be fully compressed to release the energy of the bullet; the blocking tooth 17 is formed into a strip-shaped elastic strip through the blocking tooth gap 19, and the tooth surface is a slope, which allows the core rod to be easily inserted and blocks the core rod The retaining ring 21 prevents the core rod 2 from being accidentally pulled off; the inner diameter of the inner conical head 20 is slightly smaller than the outer circle size of the matching needle seat 3, so as to achieve a tight fit effect.

[0028] refer to figure 1 , Figure 5 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com