Machining device for columnar curved toughened glass

一种曲面玻璃、钢化玻璃的技术,应用在玻璃的成型、玻璃的钢化、玻璃制造设备等方向,能够解决影响曲面玻璃精确成型、波浪形变形、辊道和风栅阵列不平行等问题,达到保证成型质量和钢化处理的品质、提高成型质量、保证一致性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]The arrangement state of each station in the columnar curved tempered glass processing device of the present invention is as follows Figure 8 As shown in , there are sequentially connected loading table 6, heating furnace 7, glass bending and forming mechanism 8, cooling and tempering mechanism 9, and unloading table 10. The output direction to the cooling and tempering mechanism 9 is perpendicular to the output direction of the high-temperature flat glass from the heating furnace 7 .

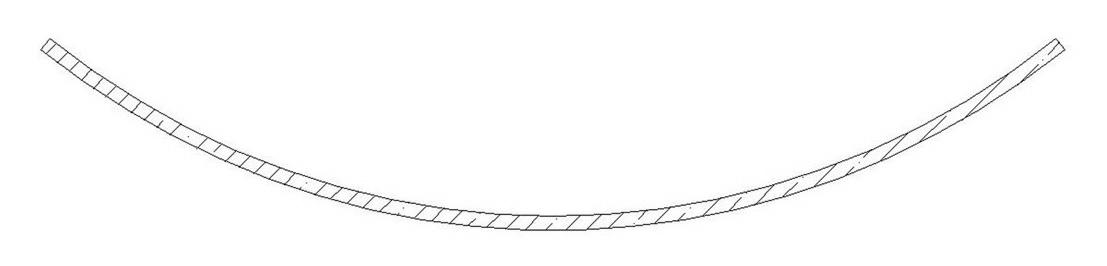

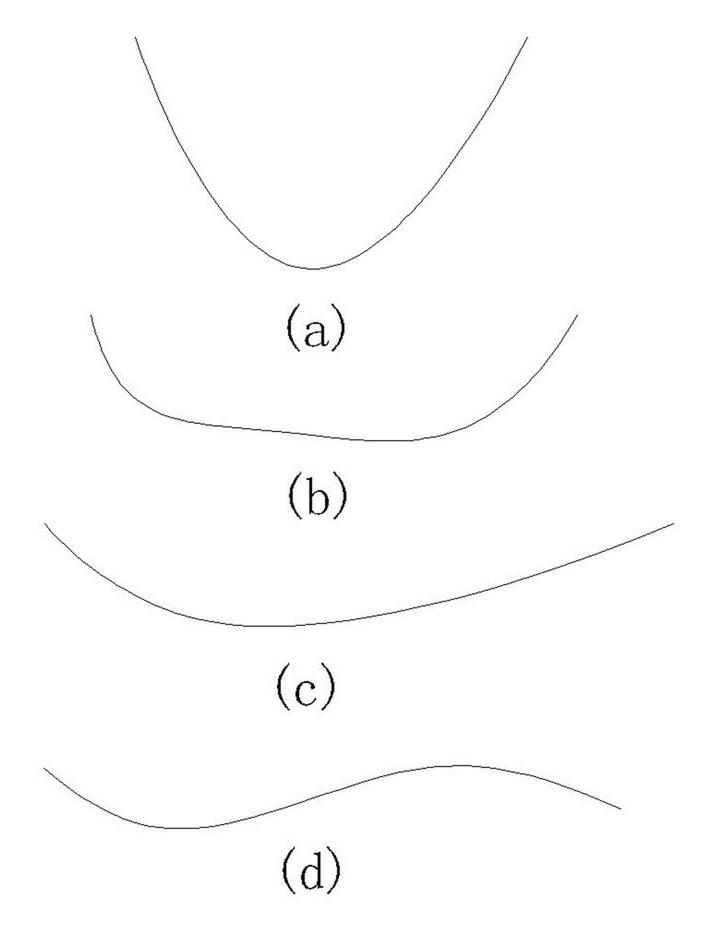

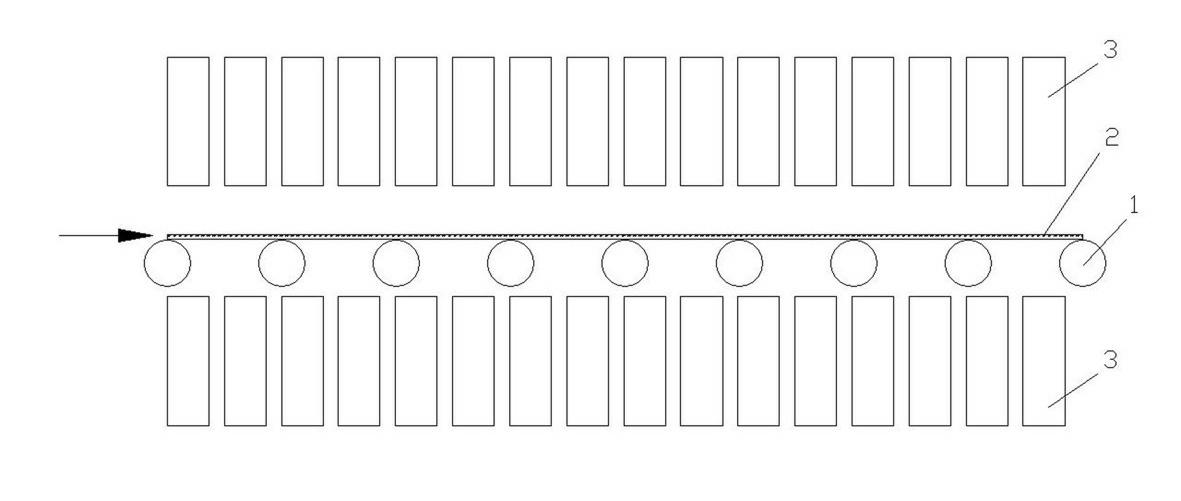

[0043] The bending forming mechanism 8 adopts the above-mentioned first forming mechanism, that is, by making the support rollers in the roller table carrying the high-temperature flat glass change from a plane arrangement to a curved surface arrangement corresponding to the shape of the glass to be formed in space, so that all The supported glass is bent and deformed, and conveying rollers 5 are arranged between adjacent supporting rollers 1 . The cooling and tempering mechanism 9 is c...

Embodiment 2

[0048] like Figure 14 As shown, in order to improve the forming accuracy of the columnar curved tempered glass, an accurate forming mechanism 11 can also be arranged between the forming mechanism 8 and the cooling and tempering mechanism 9, so that the curved glass formed by the forming mechanism 8 can be precisely formed by the precise forming mechanism 11 After processing, it is sent to the cooling and tempering mechanism 9.

[0049] like Figure 13 or Figure 14 As shown, the precise forming mechanism 11 is provided with conveying rollers 5 or soft support rollers that simultaneously clamp the upper and lower surfaces of the curved glass and simultaneously transport the curved glass forward. The rollers or supporting rollers in the precise forming mechanism are arranged according to the predetermined shape of the curved glass, and the upstream preliminary formed curved glass passes through it to complete further precise forming.

[0050]

[0051] In the above example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com