Glass plate combining apparatus used for making multilayer structure glass member

A glass plate and adjusting device technology, applied in glass forming, glass reshaping, building components, etc., can solve problems such as low efficiency, increased labor intensity of workers, difficulty in ensuring the assembly quality of multi-layer structural glass components, etc., to achieve High-efficiency production, elimination of high labor intensity, and improvement of lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

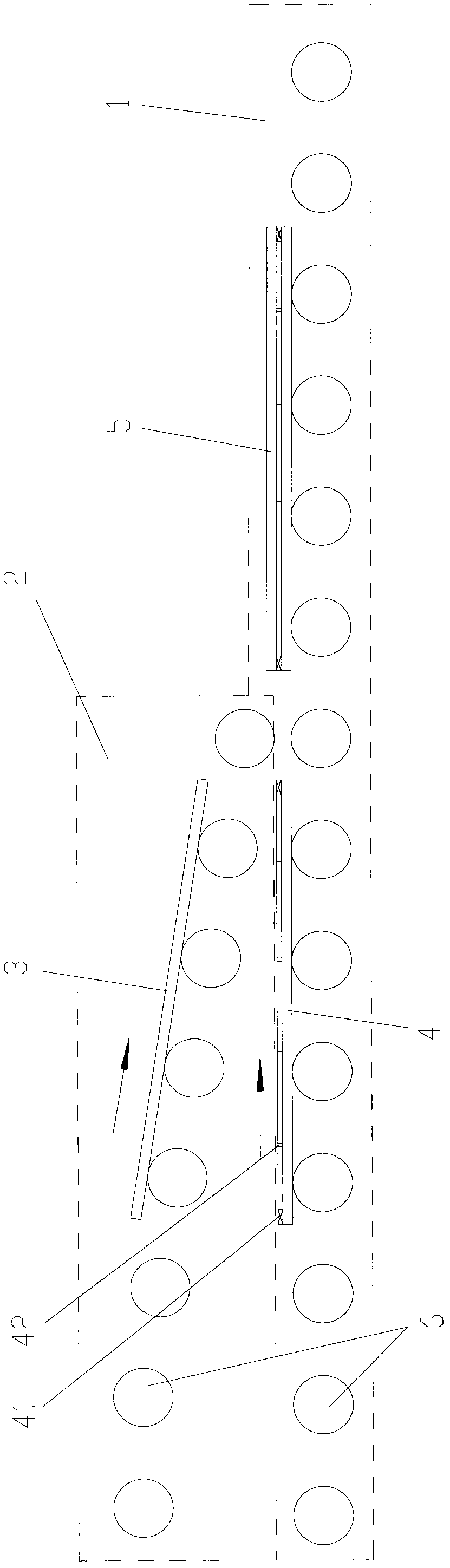

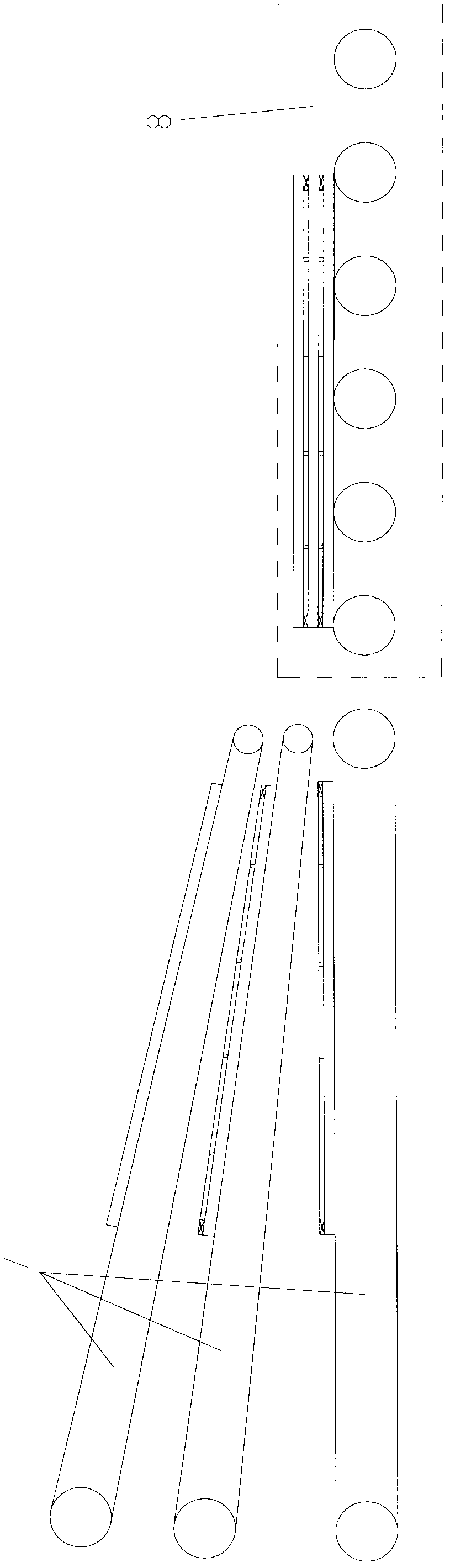

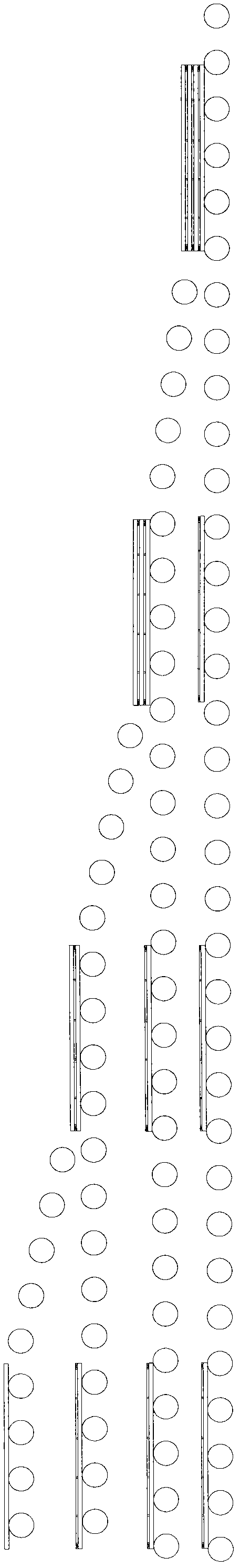

[0024] exist figure 1 In the shown embodiment 1, the glass plate merging device of the present invention is composed of two glass plate conveying mechanisms, the upper conveying mechanism 2 and the lower conveying mechanism 1 are arranged at intervals up and down, wherein the upper conveying mechanism 2 is used to convey the two-layer structural glass The upper glass plate 3 in the component 5 and the lower layer conveying mechanism 1 are used to transport the lower glass plate 4 . The upper and lower conveying mechanisms 1 and 2 are roller-type conveying mechanisms, and each conveying mechanism is formed by a plurality of glass plate conveying rollers 6 arranged in parallel with each other. The glass plate conveying surface on the lower conveying mechanism 1 is set horizontally, and, in order to enable the upper glass plate 3 to fall onto the lower glass plate 4 sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com