Mobile phone inner shell and screen fitting method and device, equipment and medium

A mobile phone screen and inner shell technology, which is applied in the lamination field of mobile phone inner shell and screen, can solve the problems of high cost, high labor intensity of manual assembly, and high failure rate of assembly results, so as to save labor costs and improve lamination efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

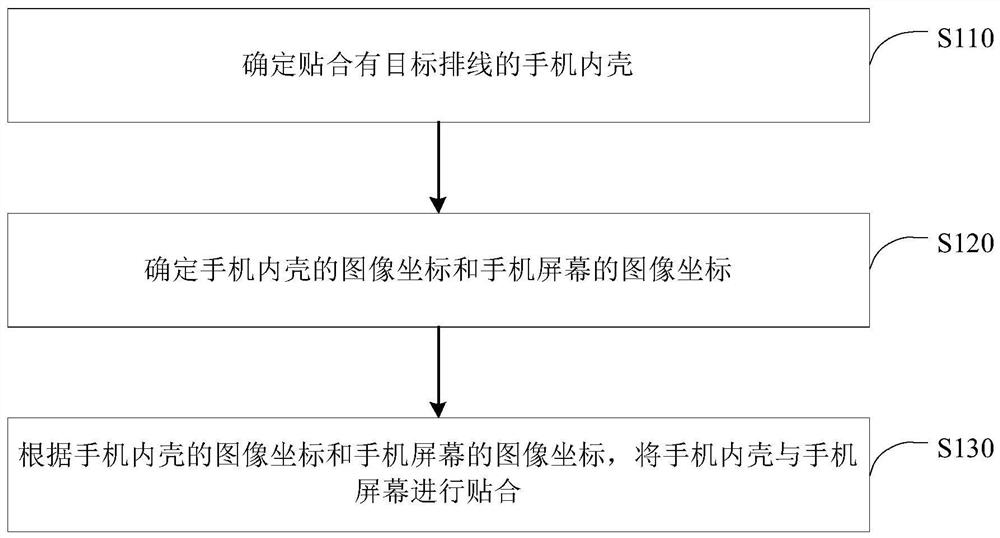

[0066] figure 1 It is a schematic flowchart of the bonding method of the mobile phone inner shell and the screen in Embodiment 1 of the present invention. This embodiment is applicable to the situation of quickly and accurately fitting the inner shell and the screen of the mobile phone. The method of this embodiment can be implemented by the bonding device of the inner case of the mobile phone and the screen, which can be realized by hardware and / or software, and can be configured in electronic equipment. The bonding method between the inner case of the mobile phone and the screen described in any embodiment of the present application can be realized. Such as figure 1 As shown, the method specifically includes the following:

[0067] S110 , determining that the inner shell of the mobile phone with the target cable is attached.

[0068] In this embodiment, the target cable is the connecting line between the inner shell of the mobile phone and the screen of the mobile phone,...

Embodiment 2

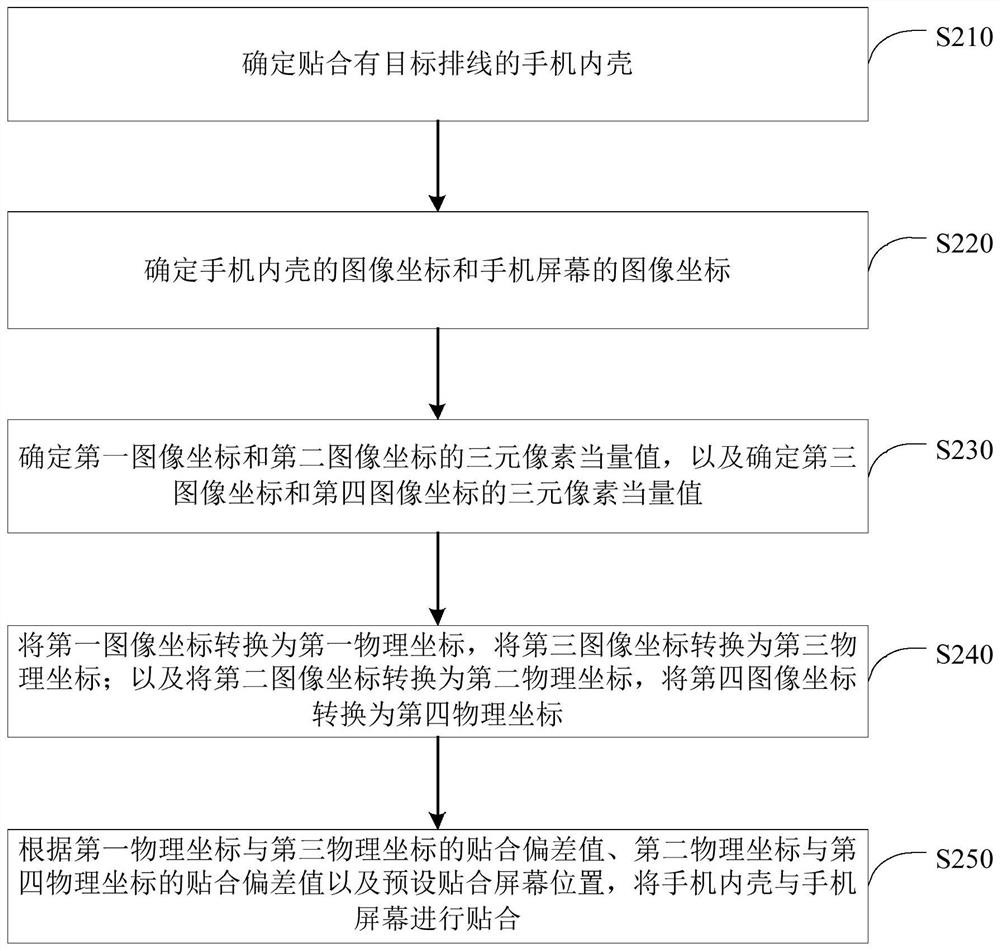

[0090] figure 2 It is a schematic flowchart of the bonding method of the mobile phone inner shell and the screen in the second embodiment of the present invention. This embodiment is further expanded and optimized on the basis of the above embodiments, and can be combined with any optional solution in the above technical solutions. Such as figure 2 As shown, the method includes:

[0091] S210 , determining that the inner shell of the mobile phone with the target cable is attached.

[0092]S220. Determine the image coordinates of the inner shell of the mobile phone and the image coordinates of the mobile phone screen.

[0093] In this embodiment, optionally, the image coordinates of the inner casing of the mobile phone include first image coordinates and second image coordinates; the image coordinates of the mobile phone screen include third image coordinates and fourth image coordinates. Specifically, the image coordinates of the inner shell of the mobile phone can be th...

Embodiment 3

[0114] Figure 8 It is a structural schematic diagram of the bonding device of the mobile phone inner case and the screen in the third embodiment of the present invention, and this embodiment is applicable to fast and accurate bonding of the mobile phone inner case and the screen. The device is configured in an electronic device, and can implement the bonding method between the inner shell and the screen of the mobile phone described in any embodiment of the present application. The device specifically includes the following:

[0115] The mobile phone inner shell determination module 810 is used to determine the mobile phone inner shell with the target cable attached;

[0116] An image coordinate determining module 820, configured to determine the image coordinates of the inner shell of the mobile phone and the image coordinates of the mobile phone screen;

[0117] The laminating module 830 is used for laminating the inner shell of the mobile phone with the screen of the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com