A bridge lead frame assembling device and assembling process thereof

A technology of lead frame and bridge lead, which is applied in the field of automation equipment, can solve the problems of low bonding efficiency, misalignment of two lead frames, high failure rate, etc., and achieve the effects of improving work efficiency, improving bonding efficiency, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

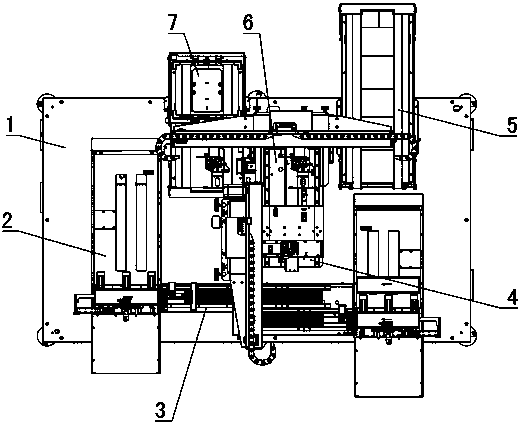

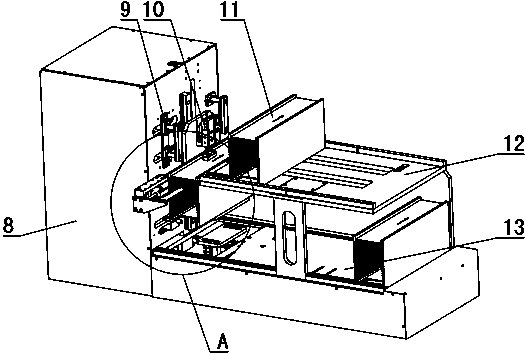

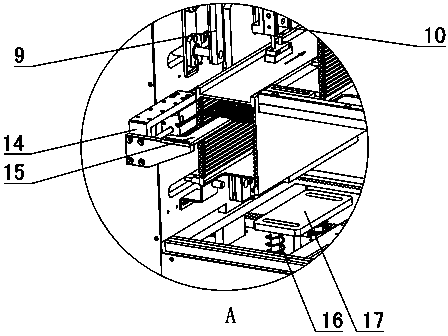

[0033] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0034] A bridge lead frame combination device, comprising a lead frame input mechanism 2 and a combination mechanism 4, there are two lead frame input mechanisms 2, and the two lead frame input mechanisms 2 are symmetrically arranged on both sides of the combination mechanism 4, and the two lead The frame input mechanism 2 transports the lead frames coated with solder paste to the sheet combination mechanism 4 respectively, and the sheet combination mechanism 4 stacks the lead frames on the welding mold 28 . The lead frame input mechanism 2 of the lead frame combination device of this bridge can deliver the lead frame coated with solder paste to the combination mechanism 4, and the combination mechanism 4 stacks two lead frames on the welding mold 28 to complete the lead frame The combined piece replaces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com