Three-way connecting component for pipe connection

A technology for connecting components and pipes, applied in the direction of connecting members, rod connections, mechanical equipment, etc., can solve problems such as affecting the aesthetics of pipe assembly products, reducing installation efficiency, and entering the interior of pipes, etc., achieving simple structure and time-saving installation. Effort-saving and friction-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

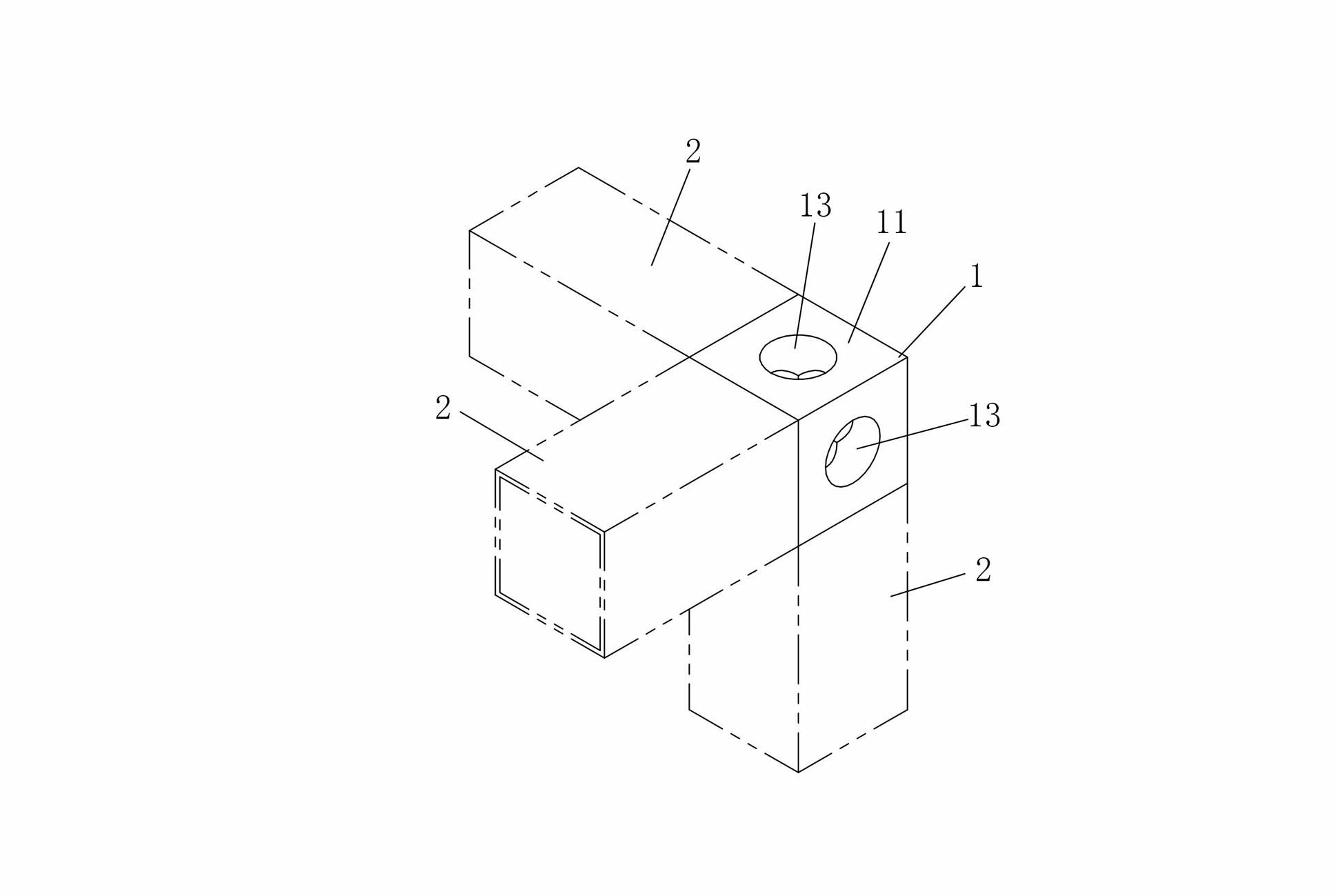

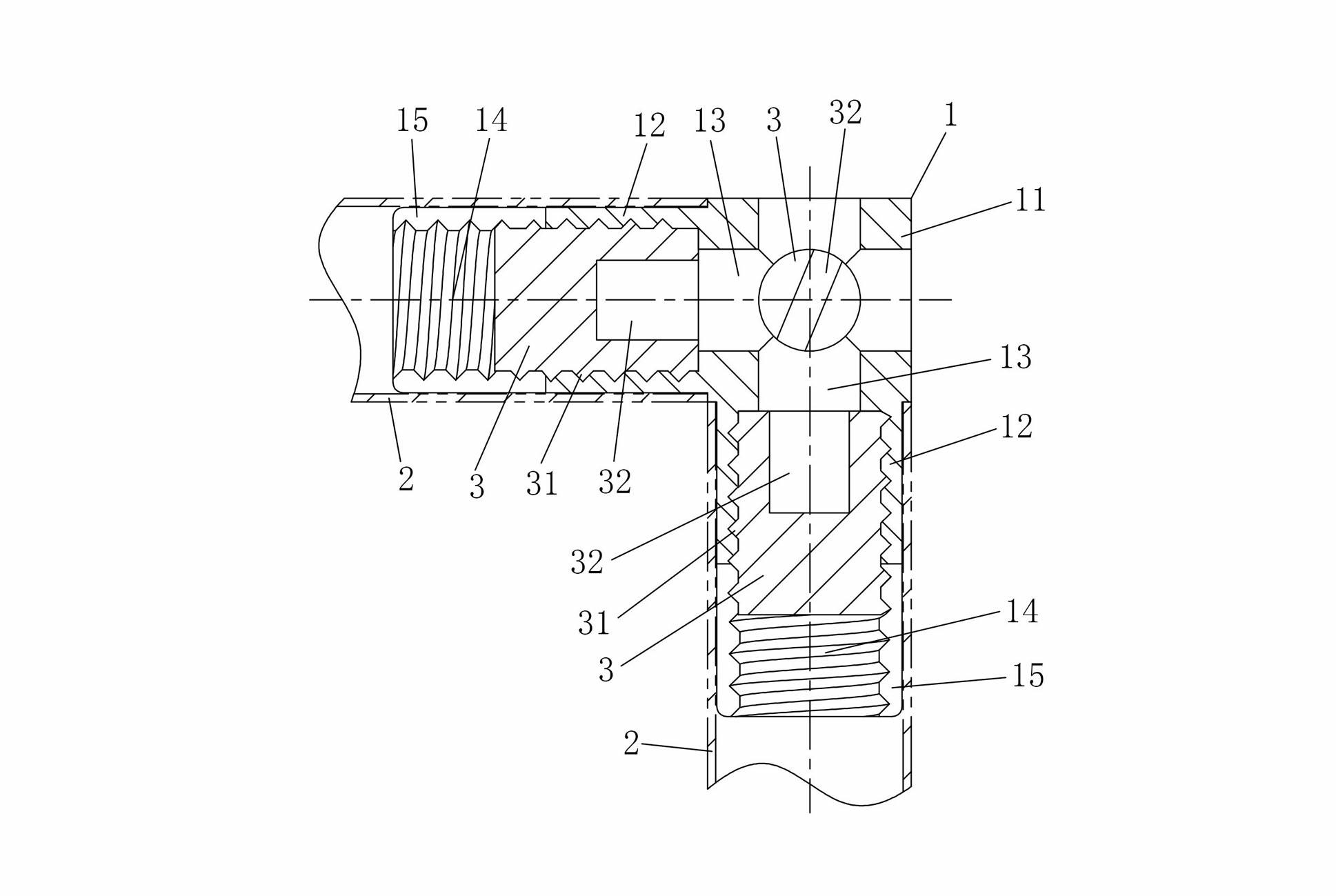

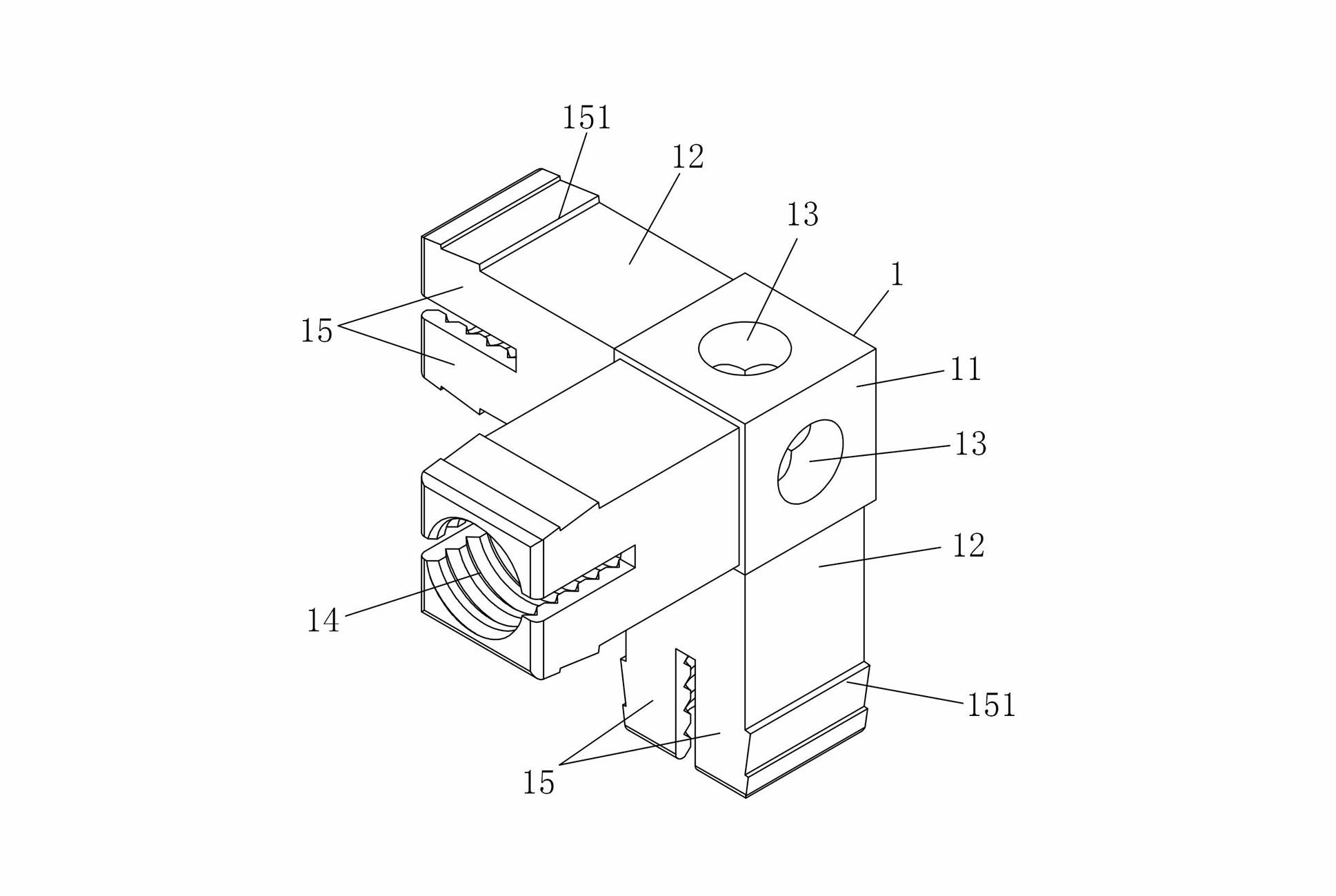

[0022] Figure 1 to Figure 4 Shows the first embodiment of the tee connection assembly for pipe connection of the present invention, including a joint body 1, the joint body 1 is provided with a connecting portion 11 and three sections of joints 12 for connecting with pipes 2, the three-section joint 12 Extending from the connecting portion 11 to three directions, each joint 12 is provided with an expansion hole 14, and the expansion hole 14 is equipped with a mandrel 3 that can make the joint 12 and the inner wall of the pipe material 2 expand tightly. Each expansion hole 14 is respectively provided with a through hole 13 for inserting the tool control mandrel 3 , and the through hole 13 extends from each expansion hole 14 to the outside of the connecting portion 11 . When in use, insert the joint 12 into the opening of the pipe mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com