High-temperature filter for biomass

A filter and high-temperature technology, applied in chemical instruments and methods, gas dust removal, dispersed particle separation, etc., can solve problems that have not been tested and applied in the industry, and achieve the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

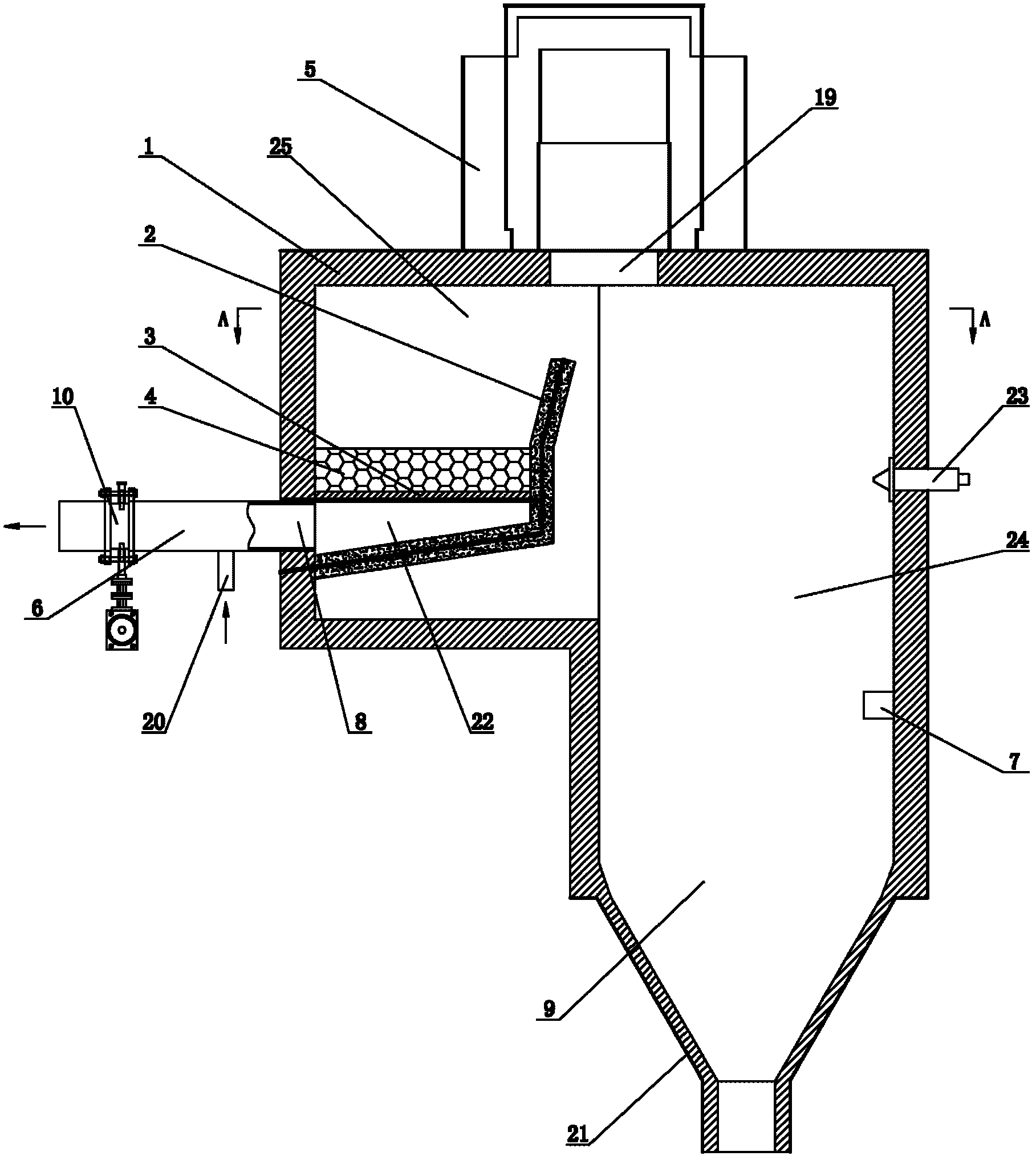

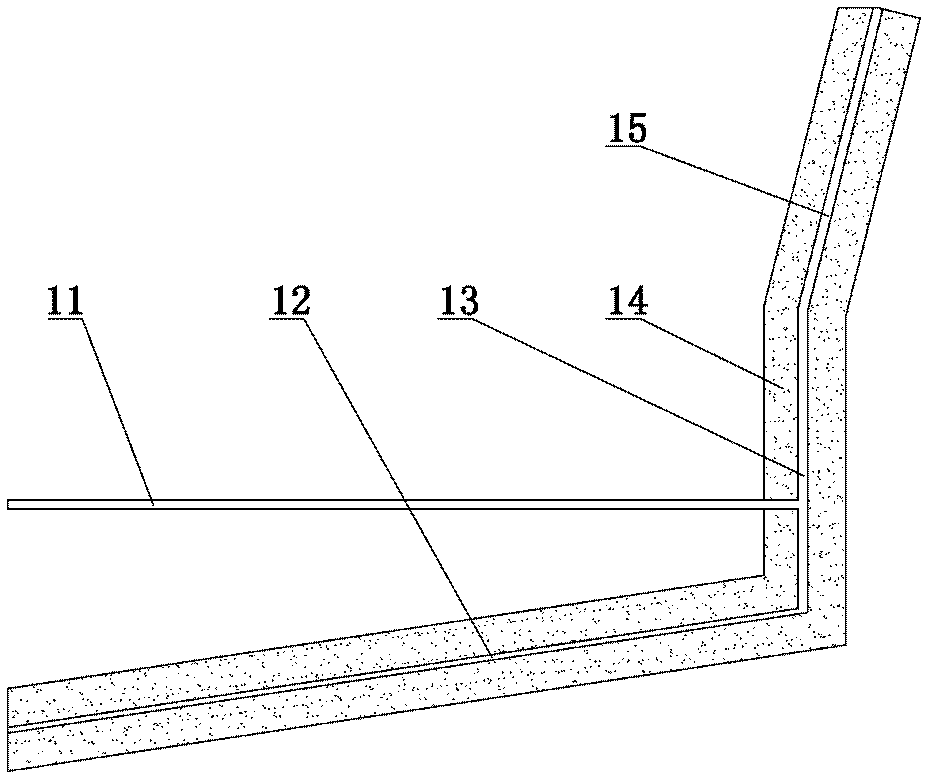

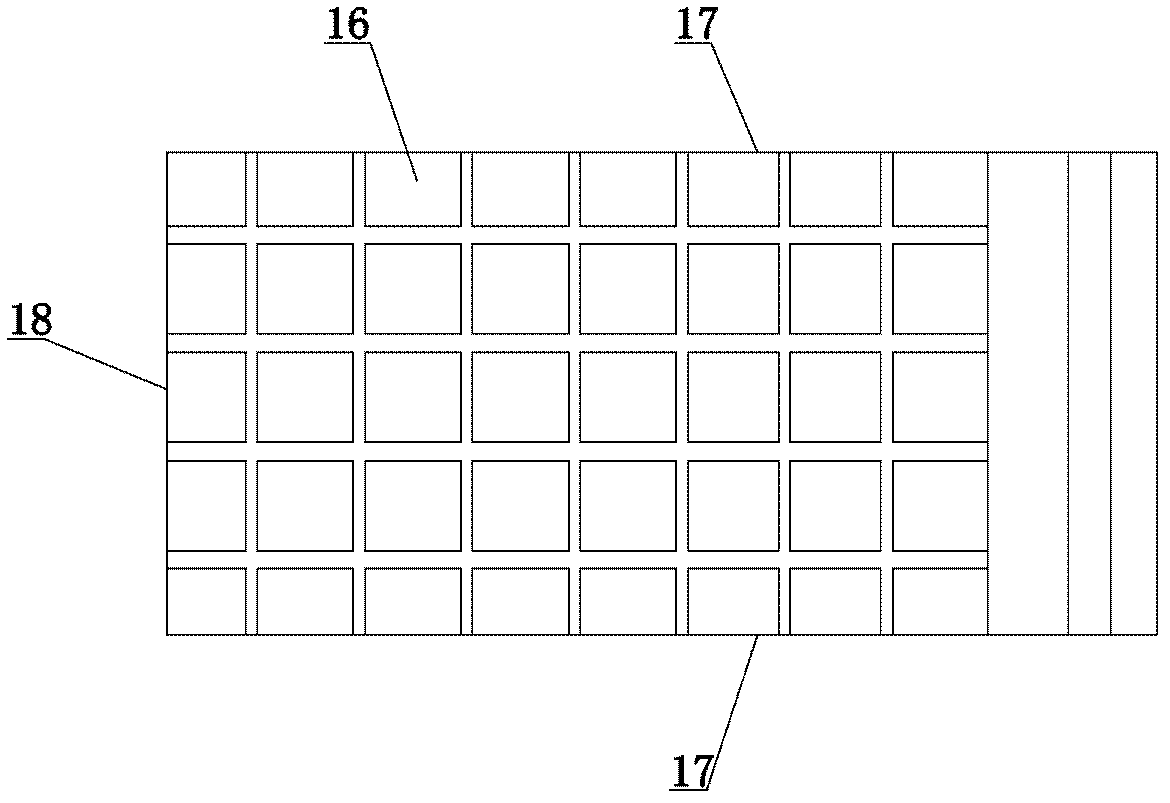

[0032] Such as figure 1 As shown, the high-temperature filter is composed of a box body 1, a filter tank 2, a filter screen 3, an explosion-proof water seal 5 and a blowback pipe 6. Casing 1 is made up of cyclone chamber 24 and filter chamber 25, and the inner cavity of cyclone chamber 24 is cylindrical, and the inner cavity of filter chamber 25 is a square, and the top of cyclone chamber 24 communicates with filter chamber 25. The side wall of the cyclone chamber 24 is provided with a gas inlet 7, and the side wall of the gas inlet 7 is tangent to the inside wall of the cyclone chamber 24 (as Figure 4 ), the position of the gas inlet 7 is located below the filter chamber 25. The side wall of the filter chamber 25 is provided with a gas outlet 8, and the lower part of the cyclone chamber 24 is provided with an impurity discharge port 9 on the right side. A filter tank 2 is installed inside the filter chamber 25. The gas outlet 8 is connected to the blowback pipe 6, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com