Sanitary basin

A sanitary pool and hygienic technology, applied in the field of sanitary pools, can solve the problems of lid appearance and durability damage, coating enamel damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

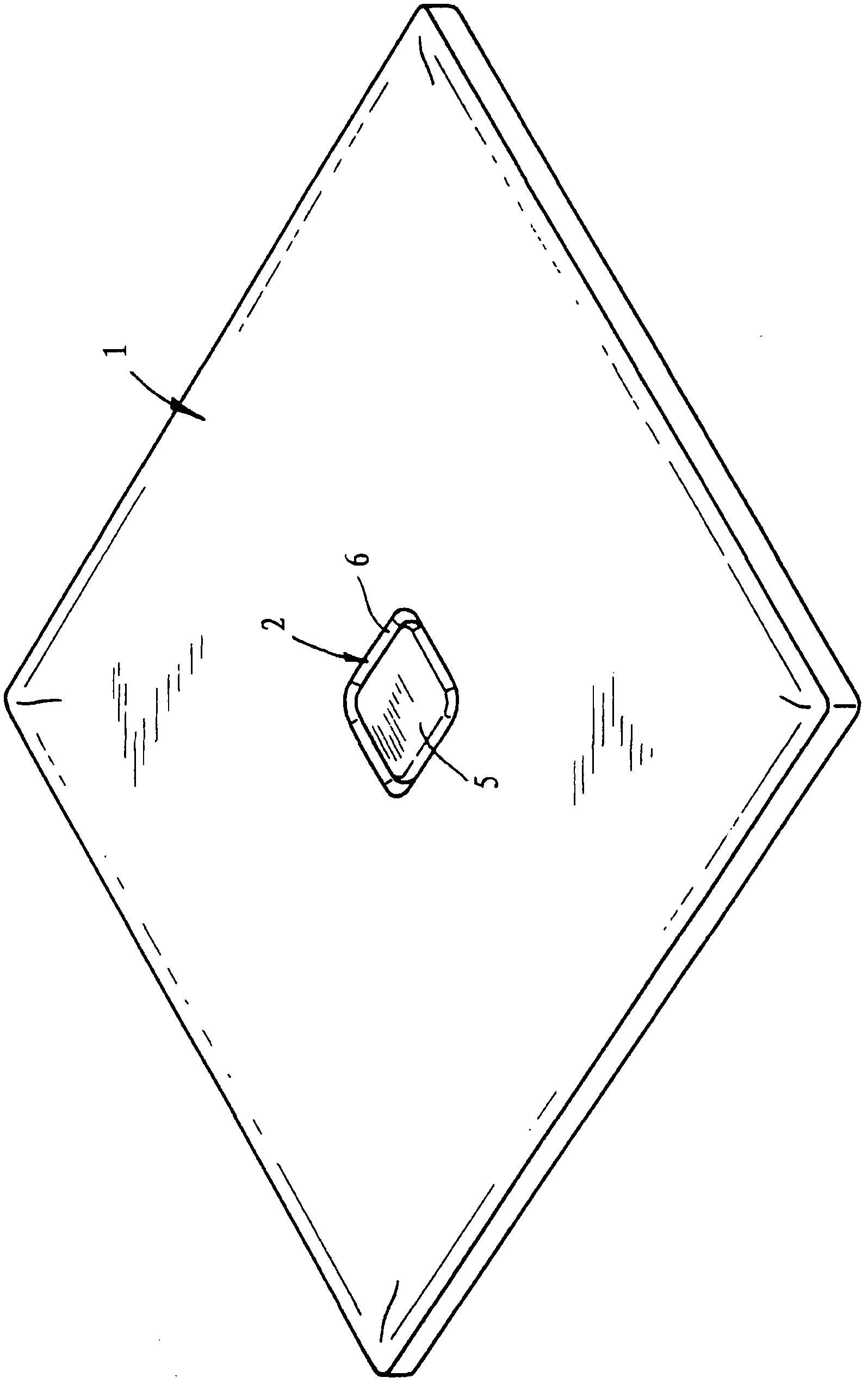

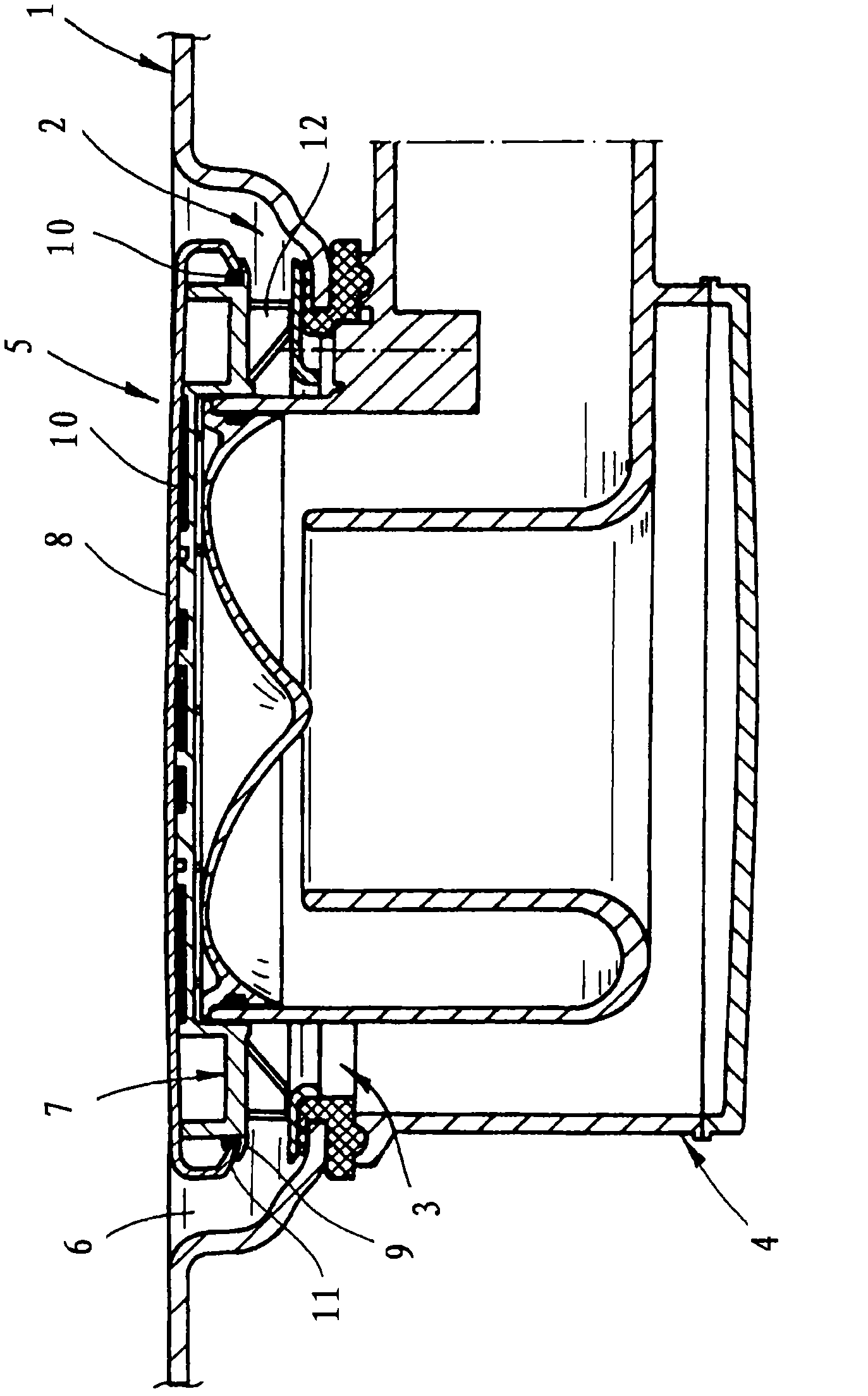

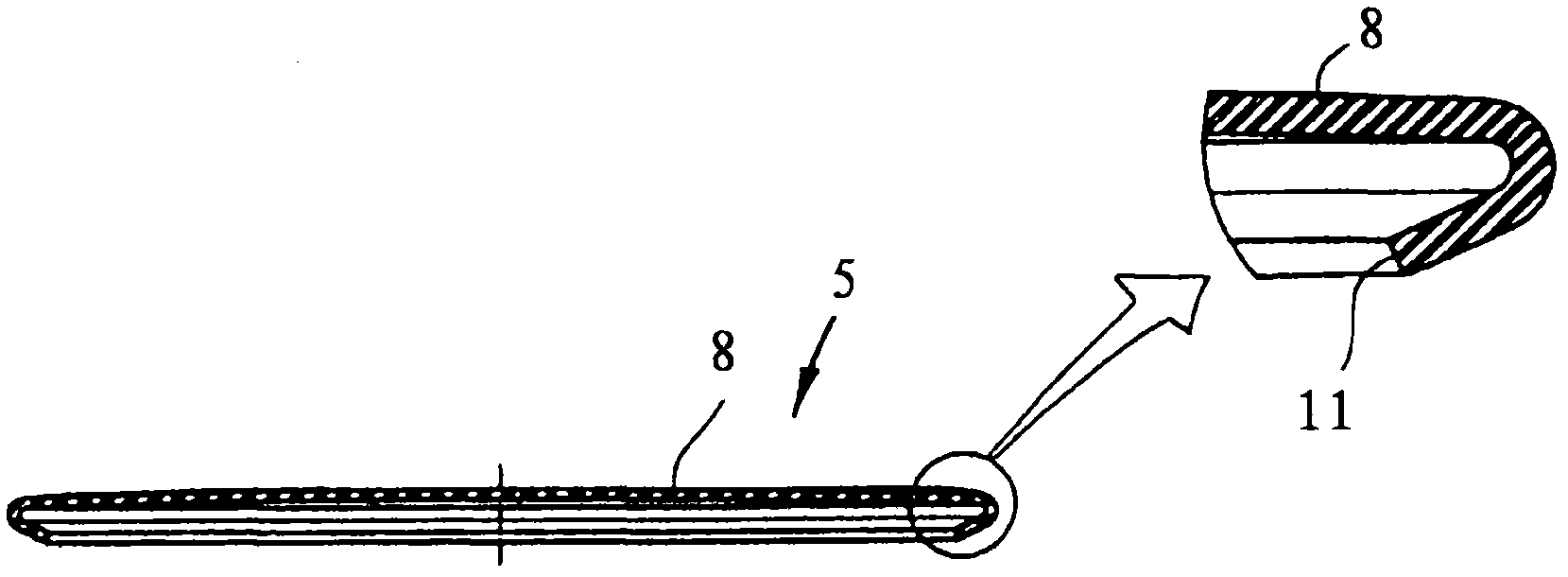

[0036] figure 1 A flat shower basin is shown by way of example with a basin bottom 1 having a drain hole 3 in a recess 2 with a drain assembly 4 connected on the underside to the drain hole 3 . exist figure 1 , the drain hole 3 including the drain assembly 4 is covered by a metal element 5 made of enamelled sheet metal arranged above them, the metal element 5 having a shape that fits into the recess 2 and between the metal element 5 and the pool bottom 1 A gap 6 for water drainage remains in between.

[0037] as in particular from figure 2 It can also be seen that the metal element 5 as a visible cover is preferably flush with the surface of the region of the tank bottom 1 adjoining the recess 2 , so that apart from the gap 6 there is a continuous surface. The metal element 5 is generally slightly bent in the direction of the edge of the metal element to ensure water drainage. However, this slight curvature is barely perceptible.

[0038] figure 2 shown in section fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com