Offset printer

A technology of offset printing and printing plates, which is applied in the field of offset printing devices, can solve problems such as lowering printing quality, achieve the effects of increasing yield, reducing manufacturing costs, and preventing printing accuracy from decreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

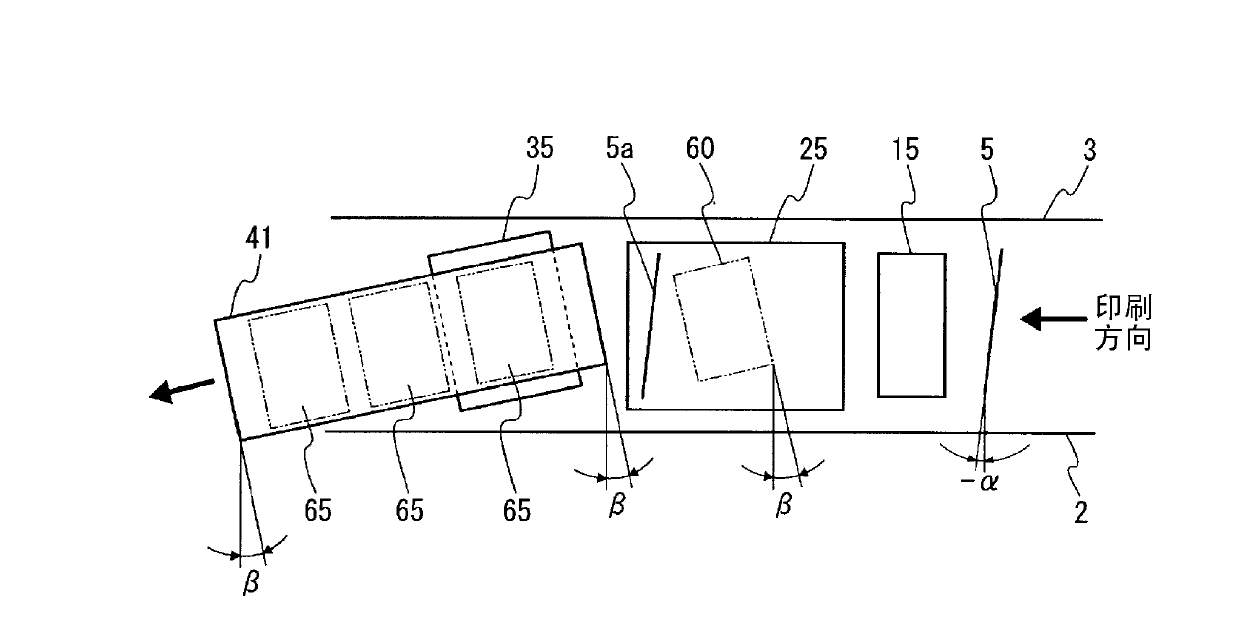

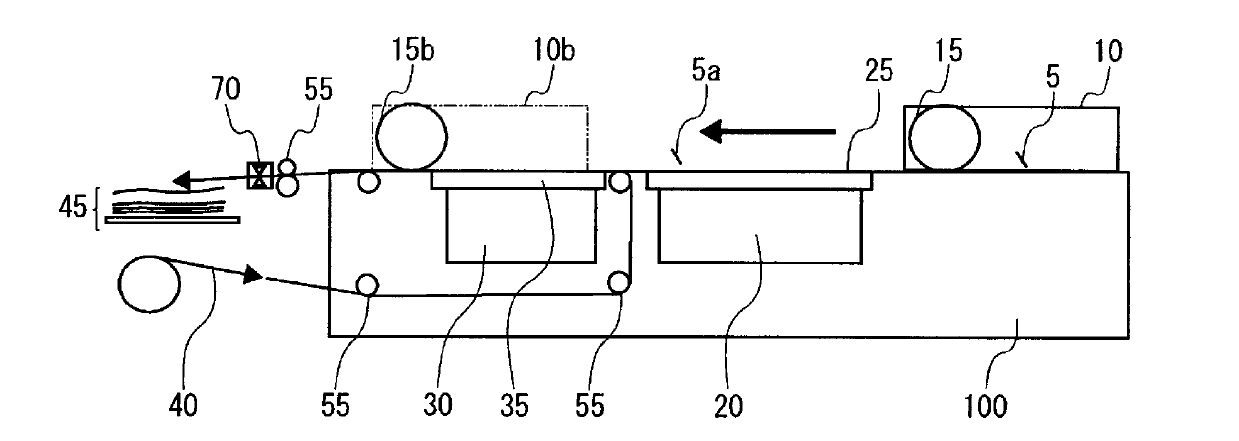

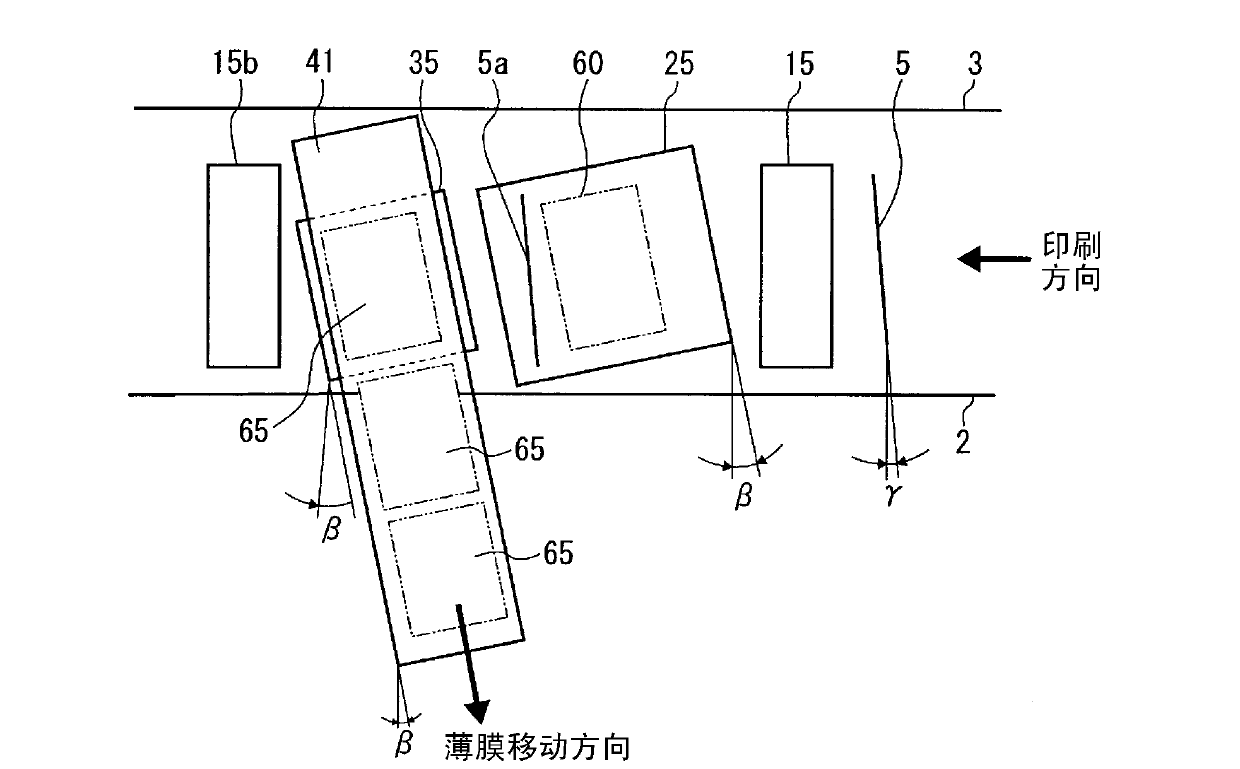

[0040] Next, preferred embodiments of the fine pattern printing apparatus of the present invention will be described with reference to the drawings. Figure 1A And 1B shows the first embodiment of the fine pattern printing device of the present invention. Figure 1A is a top view, Figure 1B are side views, and they show the schematic structure of the device. In addition, the same code|symbol is attached|subjected to the same member as the conventional offset printing apparatus 1 shown in FIG. 3, and description is abbreviate|omitted.

[0041]The fine-pattern printing apparatus 100 according to the first embodiment of the present invention is an offset printing apparatus, and as shown in the figure, the doctor blade 5 is installed obliquely with respect to the printing direction indicated by the arrow in plan view. The attachment angle -α of the squeegee 5 is an angle inclined clockwise with respect to a line perpendicular to the printing direction (a fourth inclination angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com