Sanitary outlet unit

A sanitation and discharge port technology, applied in the direction of engine components, ventilation devices, multi-way valves, etc., can solve the problems of incompletely overcome, sealing, etc., and achieve the effect of simple formation and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

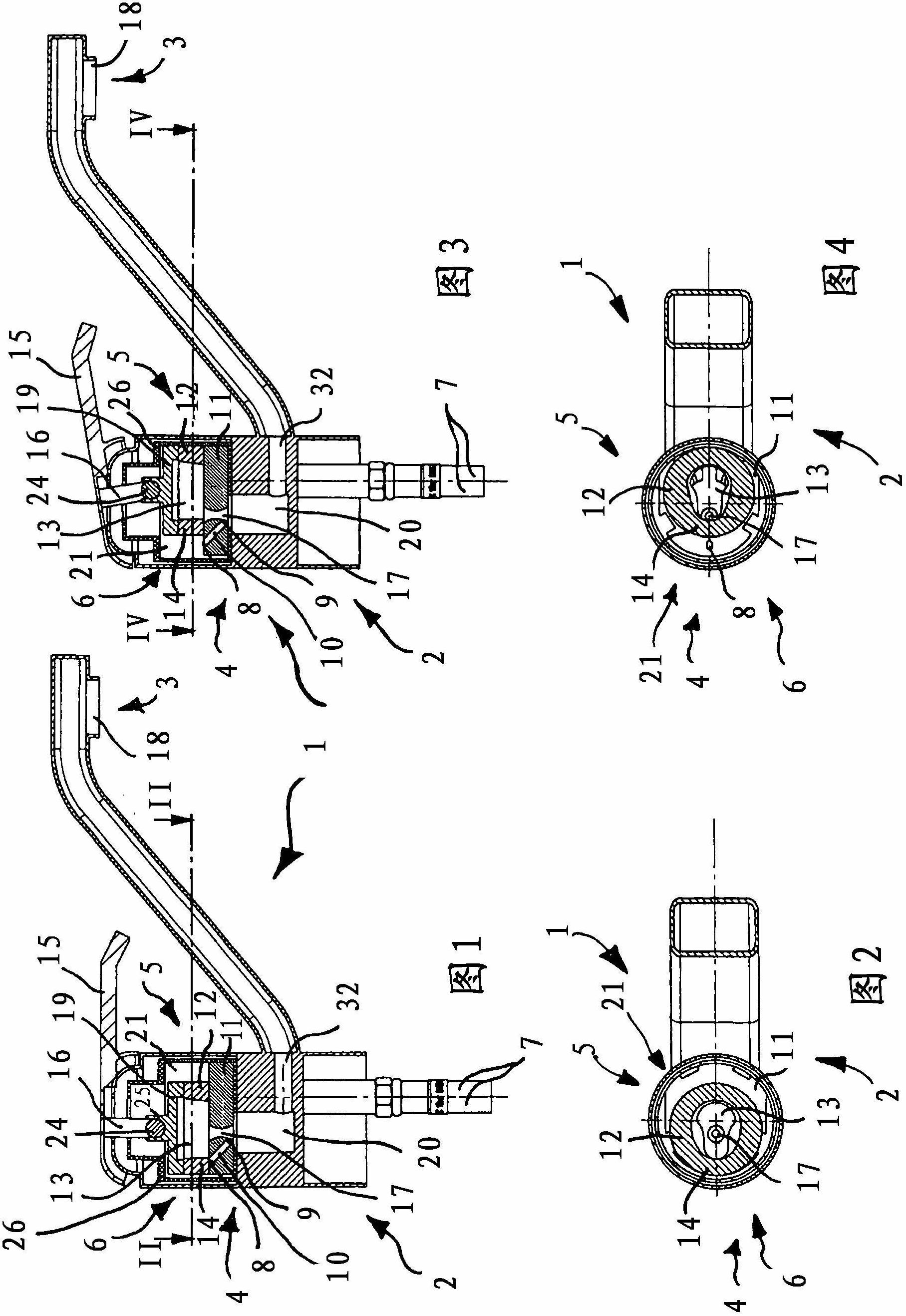

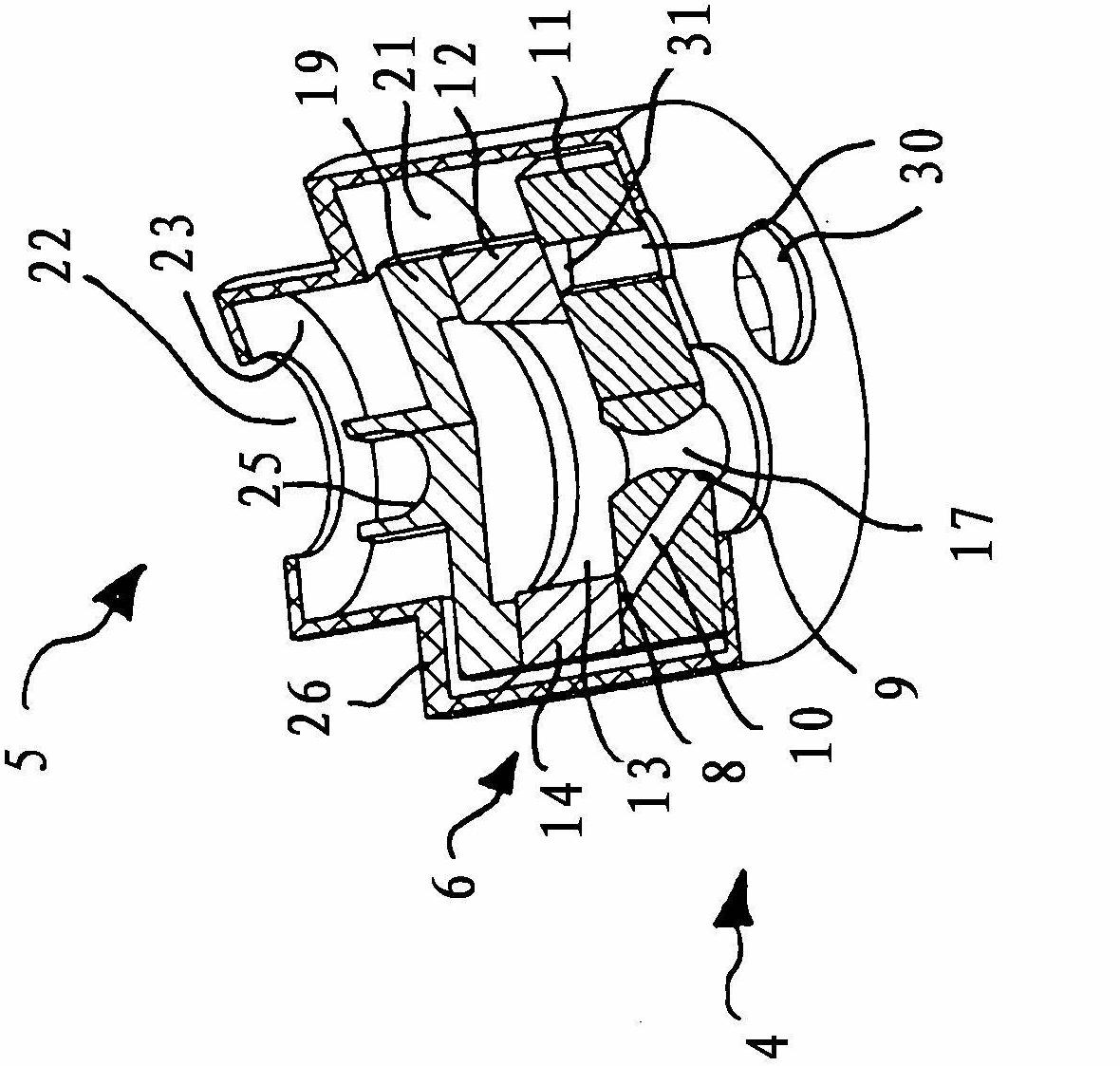

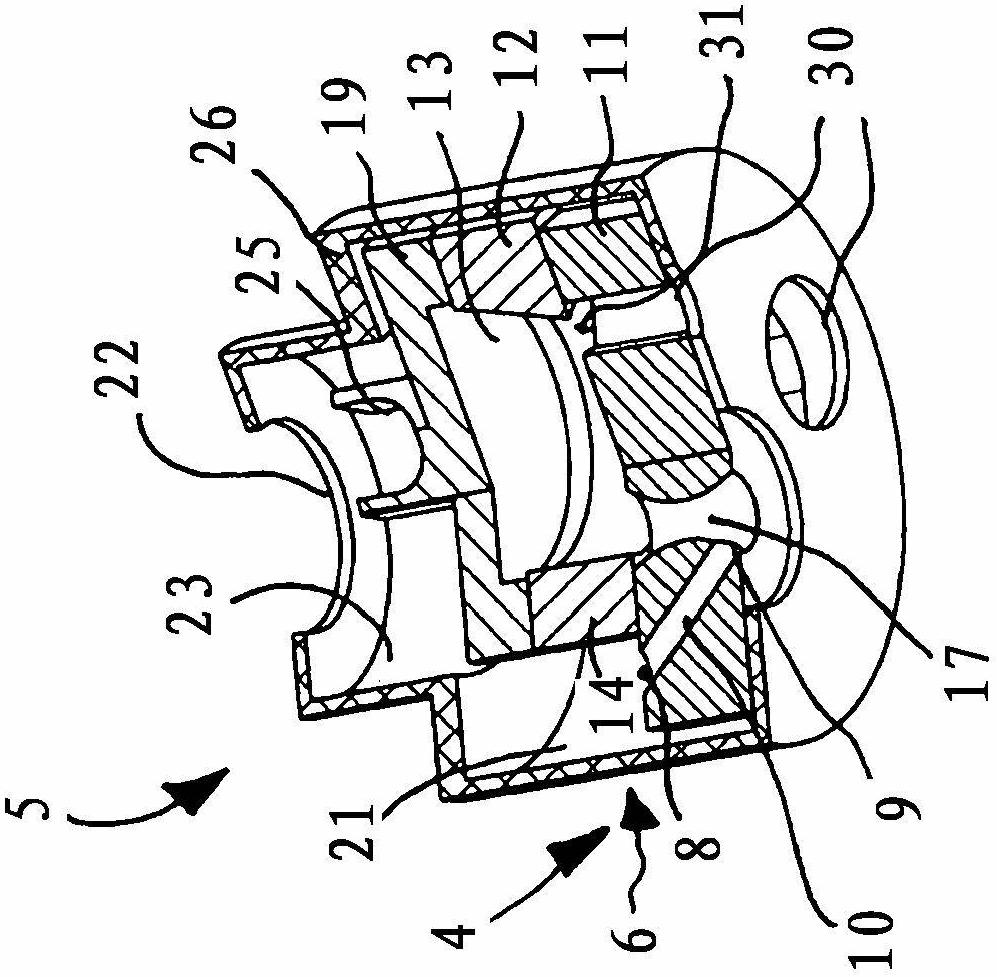

[0035] exist Figures 1 to 4 In the figure, a sanitary discharge unit with a water valve 2 can firstly be seen as a whole, which has a water outlet 3 which, due to the section along II-II and IV-IV, is not in the figure 2 and 4 shown in . as from figure 1 and 3 It can be seen from the figure that the inflow of water can be supplied to the valve member 5 through the water pipe 7, and the outflow of water from the water outlet can be adjusted through the valve member 5. To aerate the water jets, an aeration device 4 is arranged on the discharge unit 1 , which is located at a distance in the direction of flow in front of the discharge of the water outlet 3 .

[0036] as in figure 1 and 3 As seen in , the filling device 4 of the discharge unit 1 is received in the valve member 5 and is provided with an actuator 6 whose movement between an open position and a closed position changes the flow of ambient air to the interior of the valve member 5 Supply in the water jet. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com