Device for analyzing static contact characteristic of electrical appliance contact material

A contact material and characteristic analysis technology, applied in the direction of measuring devices, material resistance, instruments, etc., can solve the problem of no electrical contact pressure and contact resistance change rules, and achieve the effect of simple structure, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

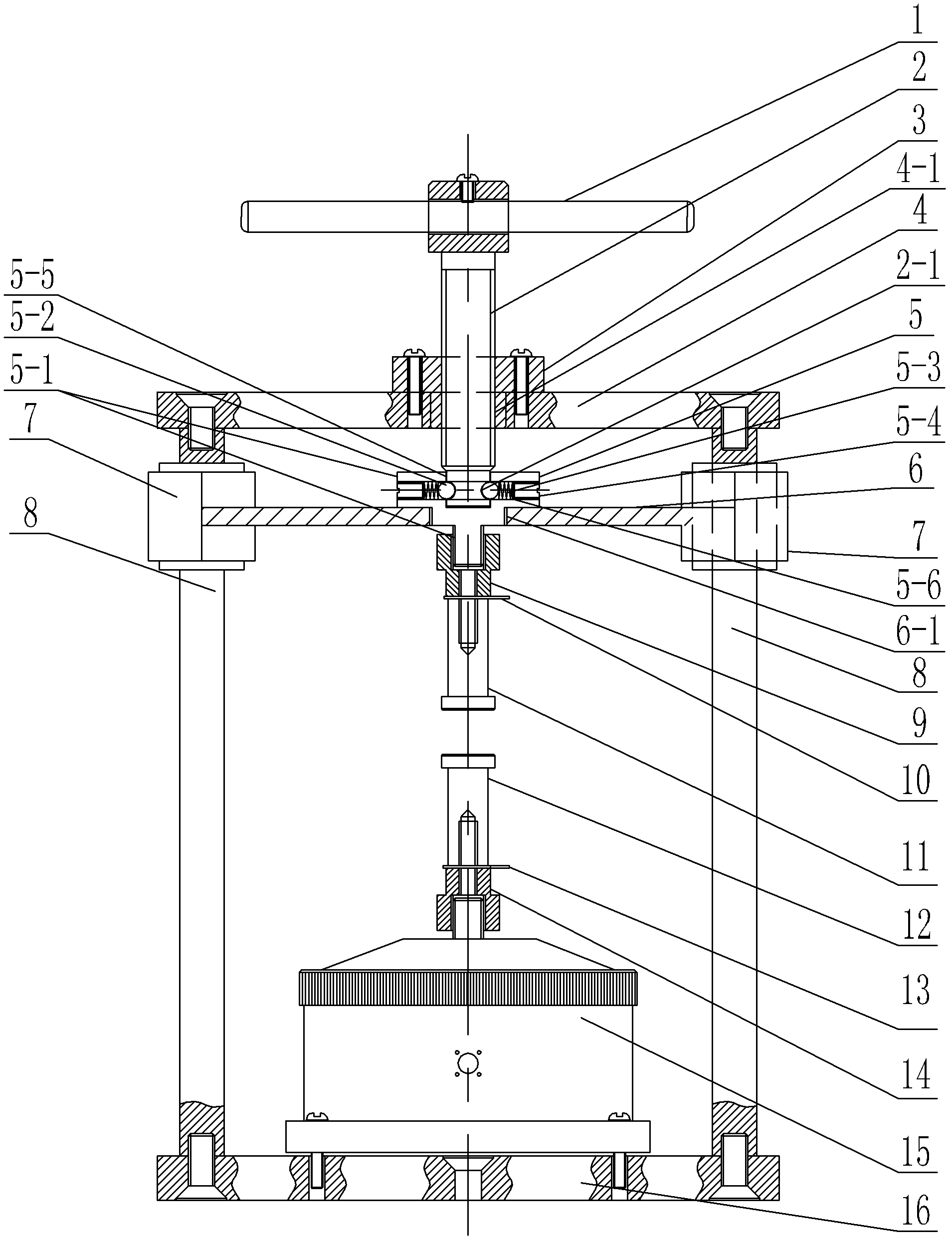

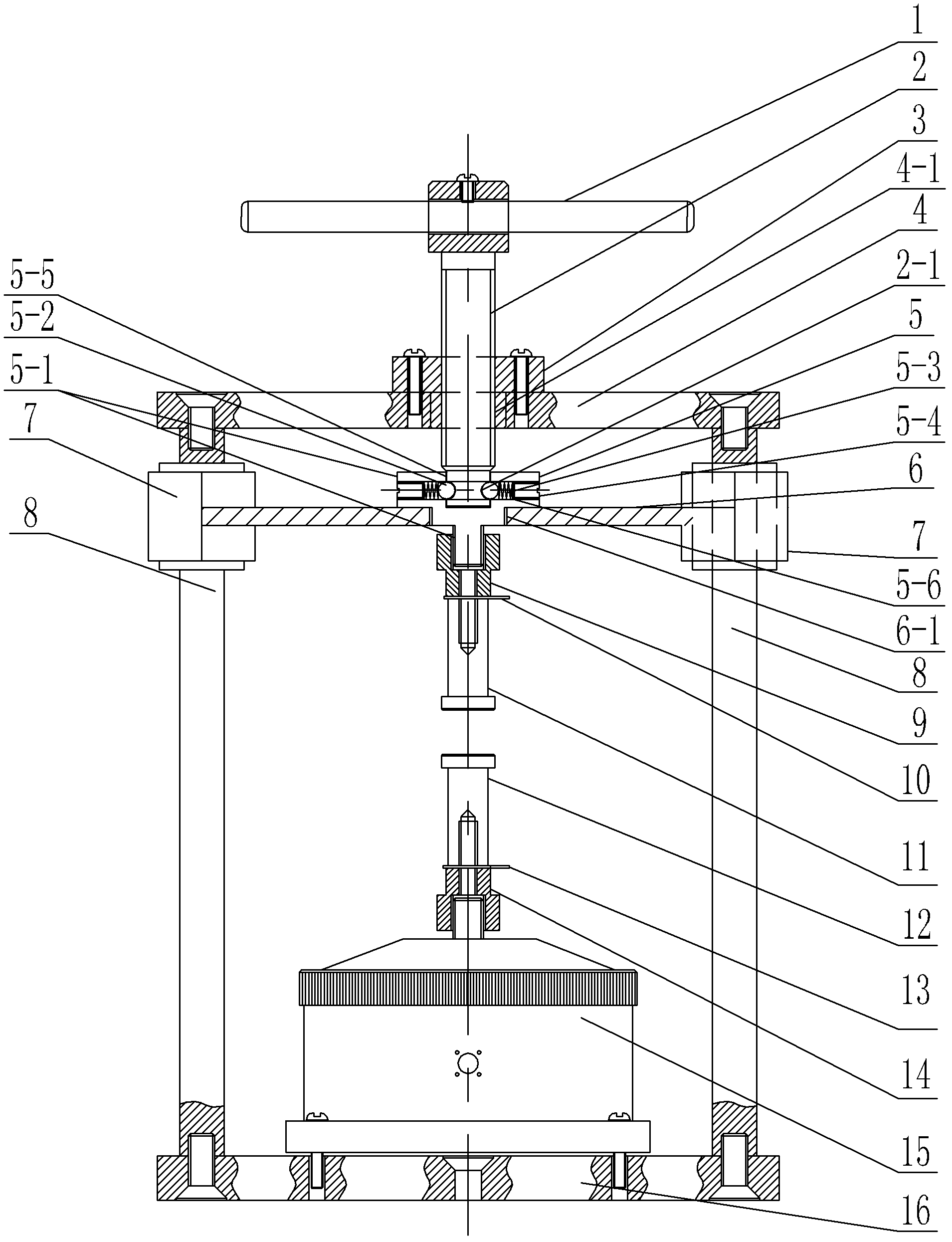

[0010] Specific implementation mode one: as figure 1 As shown, the device for analyzing static contact characteristics of electrical contact materials in this embodiment includes a rotating rod 1, a screw 2, an upper support plate 4, a screw positioning device 5, a middle pressure plate 6, an upper insulating sleeve 9, and a first terminal piece 10, second terminal piece 13, lower insulating sleeve 14, pressure sensor 15, bottom plate 16, two linear bearings 7 and two guide rails 8, and the two guide rails 8 are vertically fixed on the upper end surface of the bottom plate 16 , the pressure sensor 15 is fixed on the upper end surface of the bottom plate 16 and is located between the two guide rails 8, the upper support plate 4 is horizontally fixed on the upper ends of the two guide rails 8, and the upper support plate 4 is processed with Threaded through hole 4-1, the screw 2 is threadedly connected with the threaded through hole 4-1 of the support plate 4, the rotating lever...

specific Embodiment approach 2

[0012] Specific implementation mode two: as figure 1 As shown, the length of the guide rail 8 in this embodiment is 170-200 mm. With this design, the distance between the middle pressure plate 6 and the pressure sensor 15 is increased, thereby increasing the flexibility of selecting the shape and type of the contact material. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: as figure 1 As shown, the analysis device in this embodiment further includes a wire sleeve 3, which is threadedly connected with the lead screw 2 and fixed on the upper end surface of the threaded through hole 4-1 of the upper support plate 4. With such a design, the thread lead of the lead screw 2 can be increased, thereby enhancing the mechanical strength of the lead screw 2 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com