Full-diameter shale reservoir core bedding fracture hydration strength experimental evaluation method

A technology for full-diameter cores and shale reservoirs, applied in the direction of strength characteristics, using stable tension/pressure to test material strength, sampling, etc. Problems such as the theory of stimulation and transformation of shale reservoirs, unfavorable shale reservoir stimulation, etc., to achieve the effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

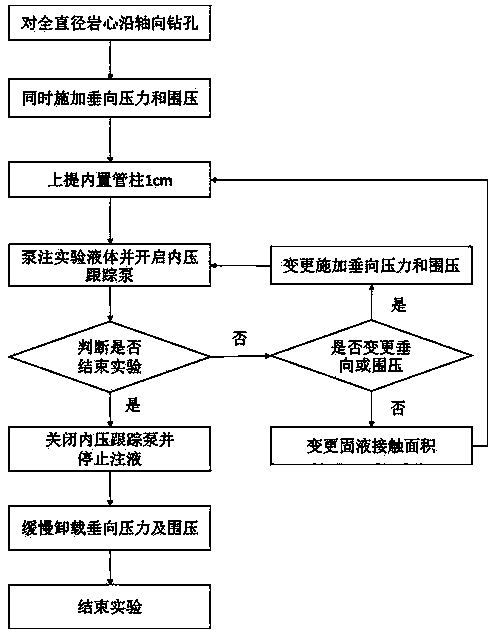

[0031] An experimental evaluation method for the hydration strength of bedding fractures in a full-diameter shale reservoir core, comprising the following steps:

[0032] a. Select a full-diameter rock core with a length of 12 cm and grind the end face of the rock core;

[0033] b. Use air cooling to drill the full-diameter core in the axial direction, the hole diameter is 2.5cm, and the distance between the drilling depth and the bottom of the core is 5cm; clean the debris residue in the hole and make the hole wall smooth and clean;

[0034] c. Put the stainless steel pump liquid pipe covered with sealing rubber sleeve into the hole, confirm the distance between the stainless steel pump liquid pipe and the bottom of the hole according to the scale of the stainless steel pump liquid pipe, and calculate whether the solid-liquid contact area meets the requirements of the experimental plan;

[0035] d. Slowly pressurize the annulus of the stainless steel pump liquid pipe and the ...

Embodiment 2

[0045] An experimental evaluation method for the hydration strength of bedding fractures in a full-diameter shale reservoir core, comprising the following steps:

[0046] a. Select a full-diameter rock core with a length of 13 cm and grind the end face of the rock core;

[0047] b. Use air cooling to drill the full-diameter core in the axial direction, the hole diameter is 2.5cm, and the distance between the drilling depth and the bottom of the core is 8cm; clean the debris residue in the hole and make the hole wall smooth and clean;

[0048] c. Put the stainless steel pump liquid pipe covered with sealing rubber sleeve into the hole, confirm the distance between the stainless steel pump liquid pipe and the bottom of the hole according to the scale of the stainless steel pump liquid pipe, and calculate whether the solid-liquid contact area meets the requirements of the experimental plan;

[0049] d. Slowly pressurize the annulus of the stainless steel pump liquid pipe and the ...

Embodiment 3

[0059] An experimental evaluation method for the hydration strength of bedding fractures in a full-diameter shale reservoir core, comprising the following steps:

[0060] a. Select a full-diameter rock core with a length of 15 cm and grind the end face of the rock core;

[0061] b. Use air cooling to drill the full-diameter core in the axial direction, the hole diameter is 2.5cm, and the distance between the drilling depth and the bottom of the core is 10cm; clean the debris residue in the hole and make the hole wall smooth and clean;

[0062] c. Put the stainless steel pump liquid pipe covered with sealing rubber sleeve into the hole, confirm the distance between the stainless steel pump liquid pipe and the bottom of the hole according to the scale of the stainless steel pump liquid pipe, and calculate whether the solid-liquid contact area meets the requirements of the experimental plan;

[0063] d. Slowly pressurize the annulus of the stainless steel pump liquid pipe and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com