Soy bottle cover

A technology for bottle caps and soy sauce, applied in the field of bottle caps, can solve the problems affecting the color, nutrition, taste of soy sauce, contact between soy sauce and air, and oxidation of soy sauce, etc., and achieve the effects of preventing continuous oxidation, being convenient to manufacture, and maintaining nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

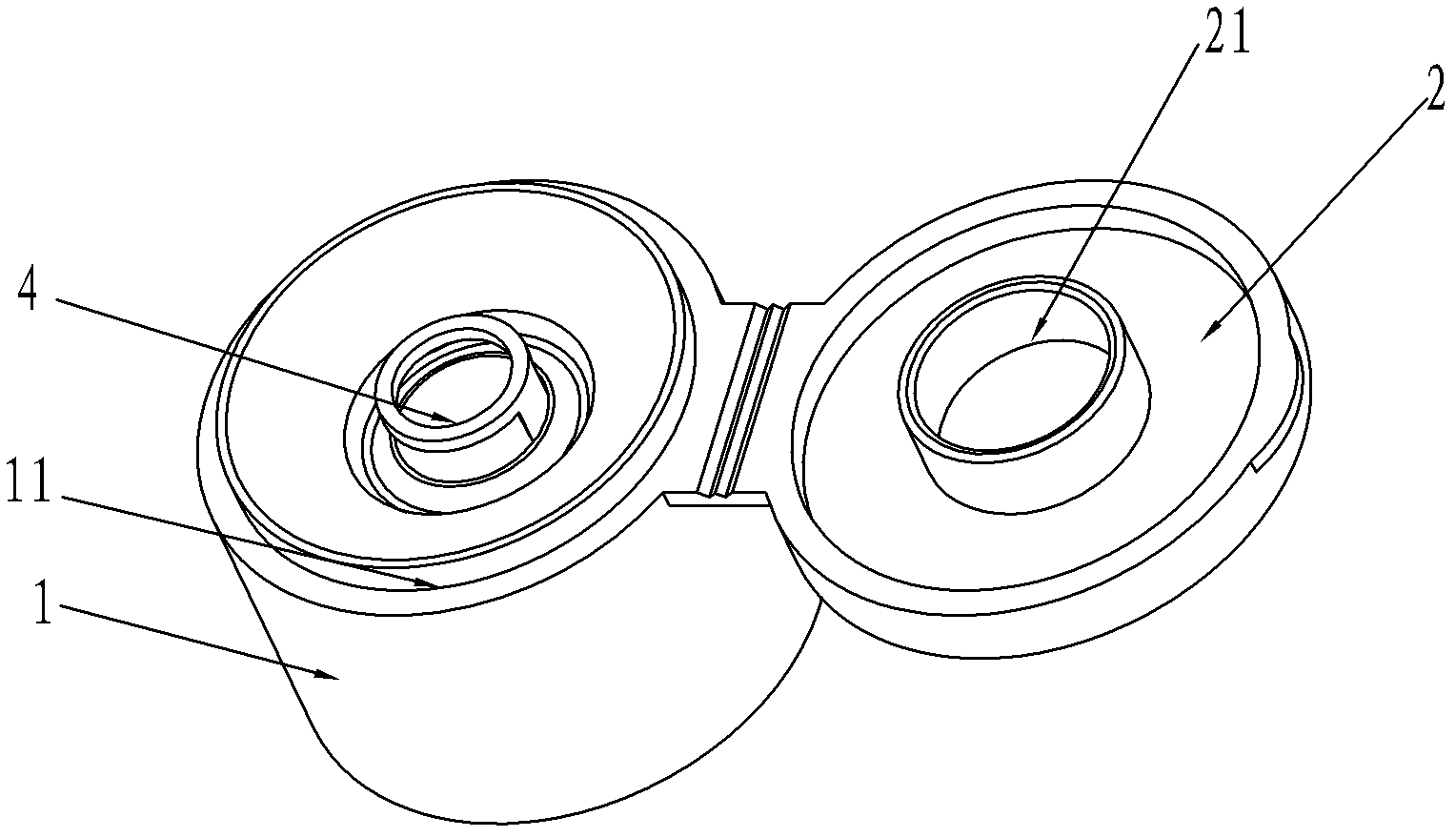

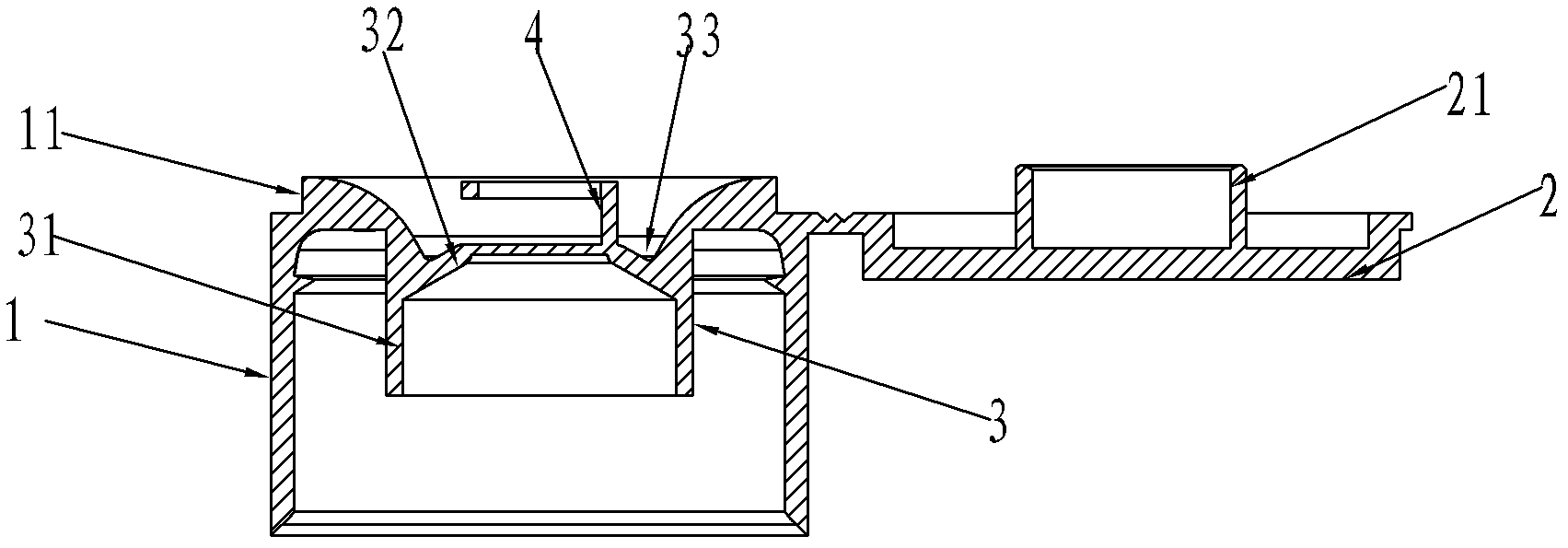

[0014] like figure 1 , 2 Shown, the soy sauce bottle cap of the present invention comprises bottle cap body 1, loam cake 2, loam cake 2 is connected with the outer wall of bottle cap body 1, and the top of bottle cap body 1 is provided with annular flange 11, and the inwall of loam cake 2 is connected with The annular flange 11 cooperates, and the upper cover 2 can be fastened on the annular flange 11 of the bottle cap body 1 . The inner side of the bottle cap body 1 is provided with an annular seal 3, the annular seal 3 includes a cylindrical outer cylinder 31 and a tapered sealing ring 32, the top and bottom of the outer cylinder 31 are open, the top of the outer cylinder 31 is connected to the annular flange 11 Connection, the outer edge of the tapered sealing ring 32 is connected to the upper part of the outer cylinder 31, an annular sealing groove 33 is formed between the outer cylinder 31 and the tapered sealing ring 32, the inner edge of the tapered sealing ring 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com