Multifunctional nursing chair bed

A multifunctional, bed and chair technology, applied in the field of patient care appliances, can solve the problems of easy access of the patient outside the basin, affecting the indoor environment, and large equipment investment, so as to improve indoor air quality, reduce labor intensity, and improve quality of life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

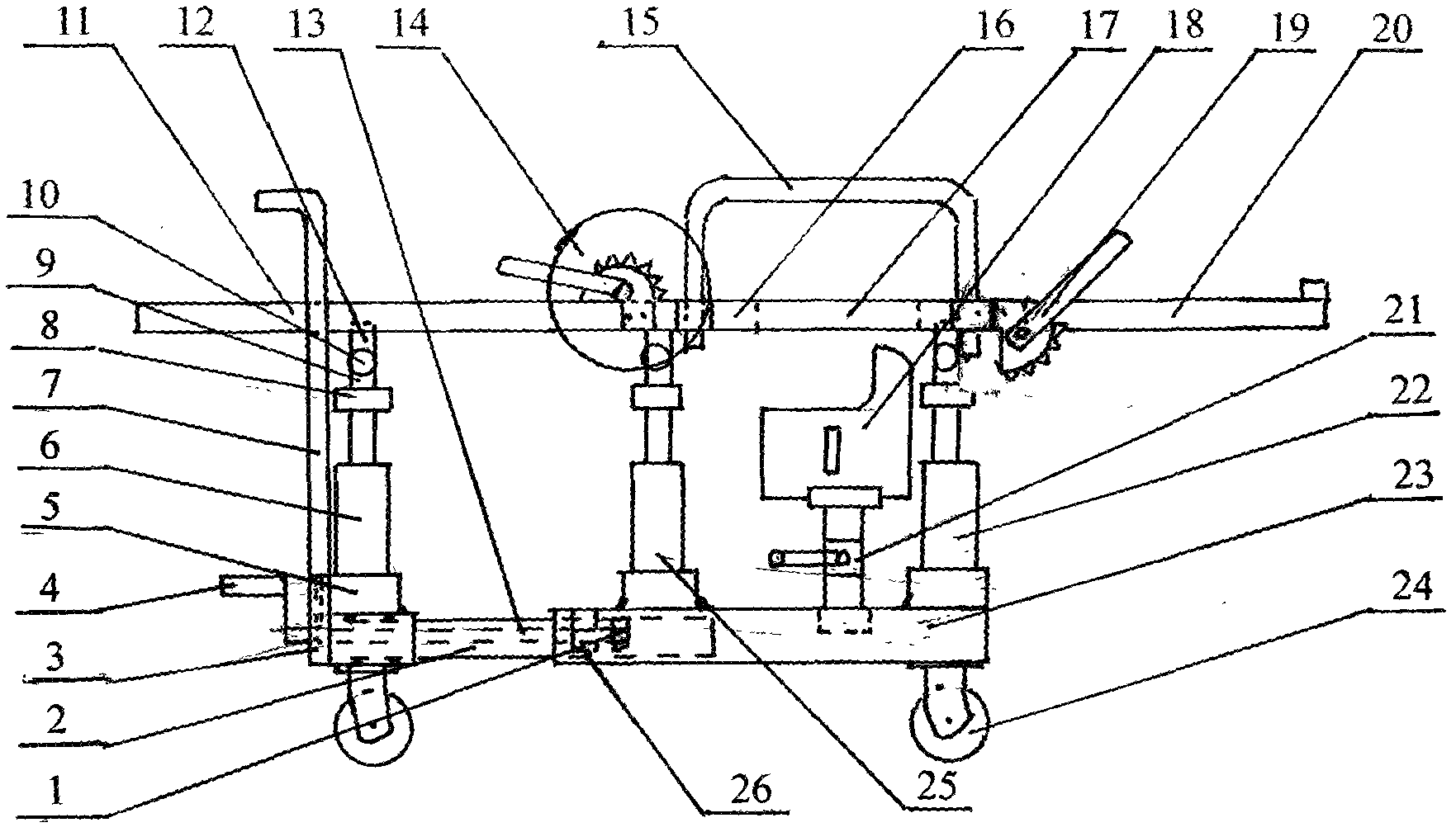

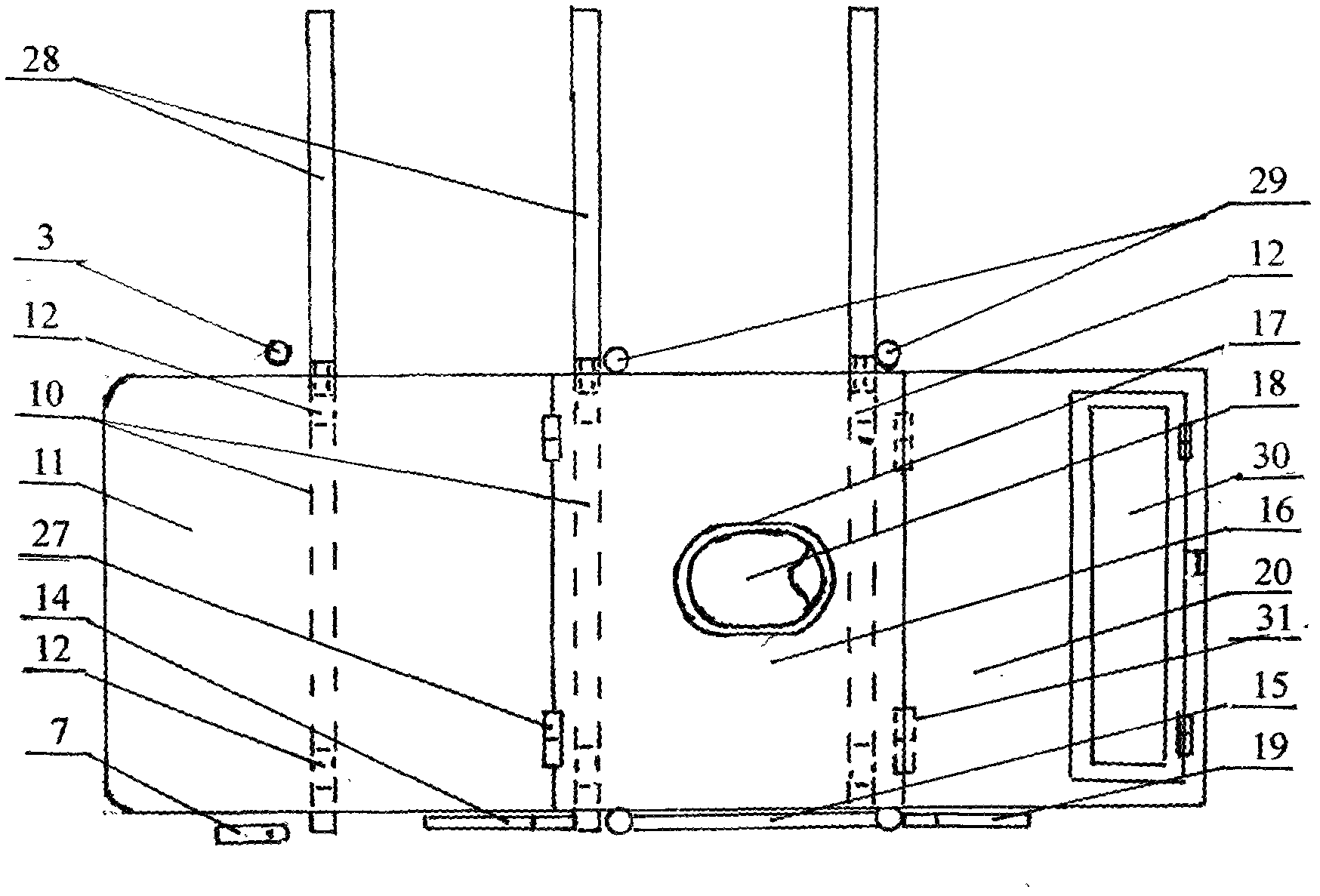

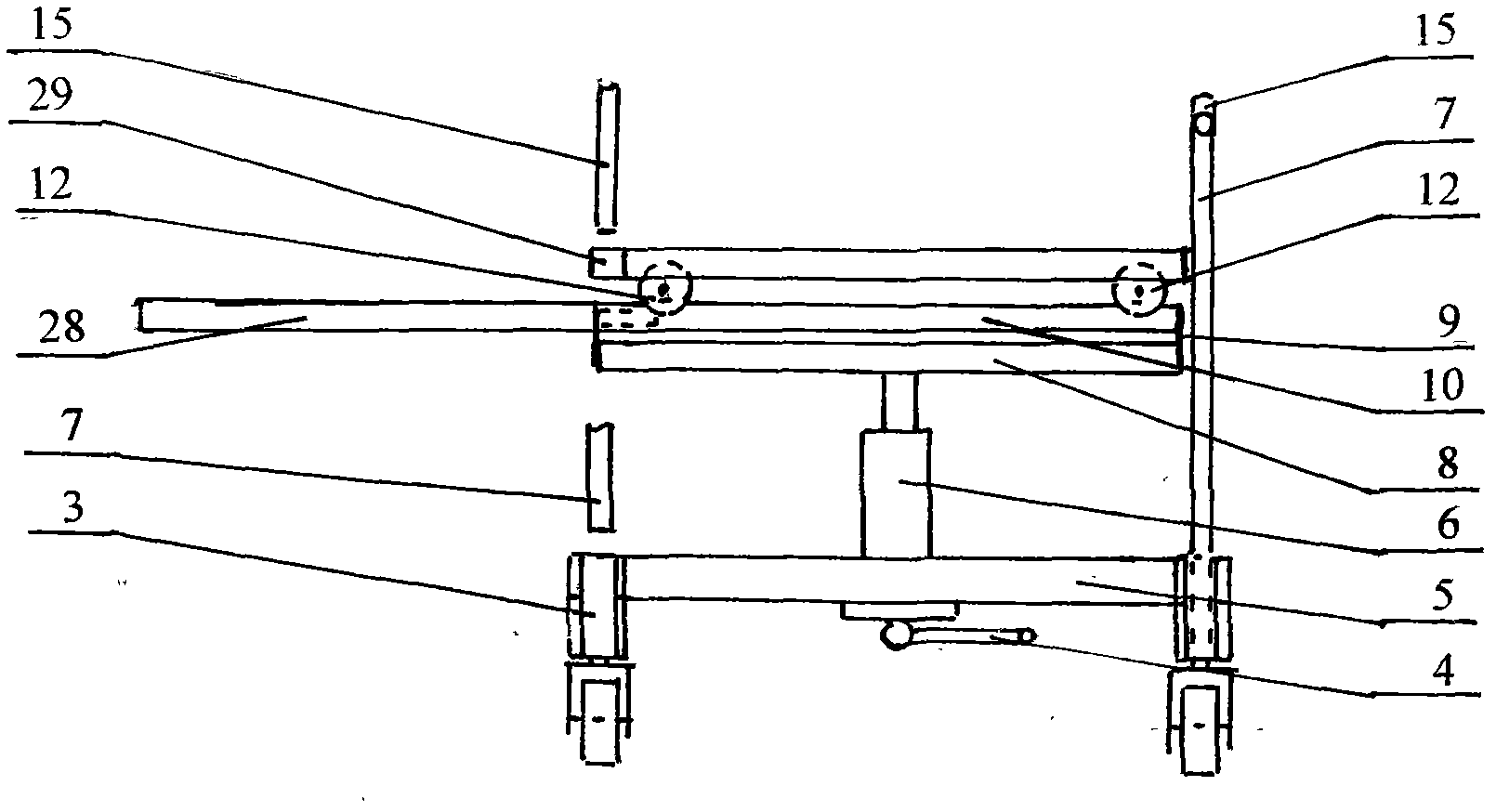

[0006] Specific implementation mode one: (see Figure 1 ~ Figure 4 ) This embodiment consists of a limit block 1, a pull pipe 2, a movable frame 5, a hydraulic cylinder 6, a tubular track 10, a backboard 11, a running wheel 12, a screw 13, a backrest angle regulator 14, a seat board 16, Knee bend angle regulator 19, calf plate 20, c hydraulic cylinder 22, fixed frame 23, b hydraulic cylinder 25; a hydraulic cylinder 6 is fixed on the movable frame 5, b hydraulic cylinder 25 and c hydraulic cylinder 22 are fixed on the fixed frame 23, the tops of a hydraulic cylinder 6, b hydraulic cylinder 25 and c hydraulic cylinder 22 are fixed below the middle part of the bracket 8, the upper ends of the bracket 8 are fixed with track brackets 9, and the top of the track bracket 9 is provided with a tubular track 10 , the two ends of the movable frame 5 are fixed with a drawing tube 2, the other end of the drawing tube 2 is arranged in the two ends of the fixed frame 23, the middle part of ...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see Figure 1 to Figure 5 ) The difference between this embodiment and the specific embodiment one is that a hydraulic cylinder 6, b hydraulic cylinder 25 and c hydraulic cylinder 22 are fixed on the lower frame 32, and two ends of the lower frame 32 are provided with two bed heads 35, two The root cross arm 33 is fixedly connected with the inner sides of the middle and upper parts of the two headboards 35, the cross arm 33 is provided with a cross arm guardrail jack 34, the guardrail 15 is inserted in the cross arm guardrail jack 34, and the base of the scissor lifter 21 is fixed. on the lower frame 32 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0008] Specific implementation mode three: (see Figure 1 to Figure 7 ) The difference between this embodiment and the second embodiment is that the c hydraulic cylinder 22 is fixed on the lower frame 32, a branch pipe 37 is fixed above the bracket 8, and horizontal support rods 36 are fixed on the inside of the two cross arms 33, and the backrest Plate 11 is fixed with backboard bushing 40, seat board 16 is fixed with seat board bushing 41, backrest board bushing 40 and seat board bushing 41 are provided with shaft 39, and the two ends of shaft 39 are covered with limit sleeve 38, The two ends of axle 39 are fixed on two cross arms 33. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com