Mould for manufacturing special cable

A cable and special-shaped technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as unsuitable for making cables, unfavorable overhead laying, and large outer diameter of optical cables, achieving high mechanical reliability and reducing processes Quantity, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

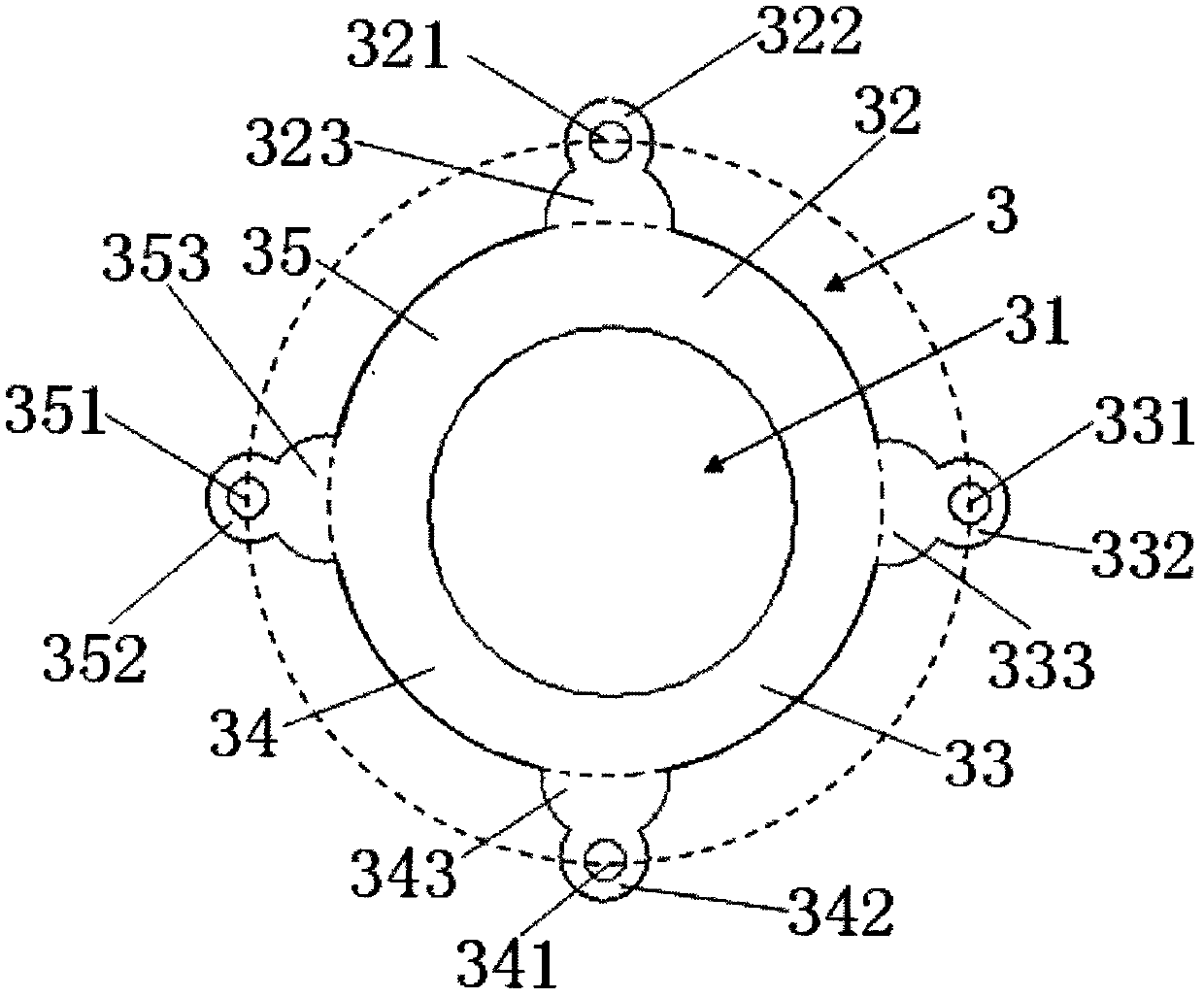

[0048] please see figure 1 and figure 2 , the special-shaped cable 3 is characterized in that it comprises a first special-shaped body, a second special-shaped body, a third special-shaped body, a fourth special-shaped body, a sheath, and a cable core 31; wherein, the first special-shaped body includes: a first reinforced Part 321, the first special-shaped member 322 covering the first reinforcement, the first connecting rib 323 connecting the first special-shaped member and the sheath; the second special-shaped body includes: the second reinforcement 331, covering the second reinforcement The second special-shaped member 332 of the piece, the second connecting rib 333 connecting the second special-shaped member and the sheath; the third special-shaped body includes: the third reinforcement 341, the third special-shaped member 342 covering the third reinforcement, connecting The third connecting rib 343 between the third special-shaped member and the sheath; the fourth spec...

Embodiment 2

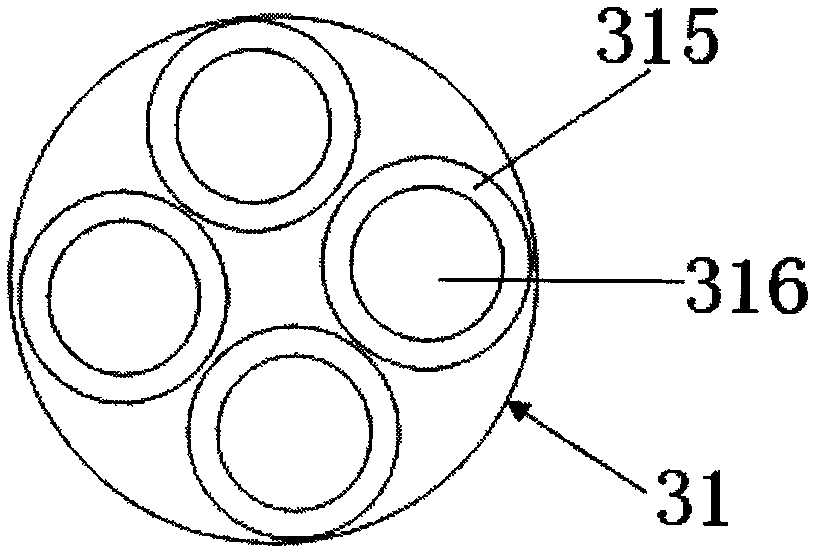

[0052] please see figure 1 and image 3 , special-shaped cable 3, basically the same as the implementation example 1, the difference is that: the cable core is composed of a plurality of insulated wires, the insulated wires are parallel to each other or twisted with each other, and each insulated wire is composed of an inner conductor 316 and a wrapped An insulating layer 315 covering the conductor is formed.

Embodiment 3

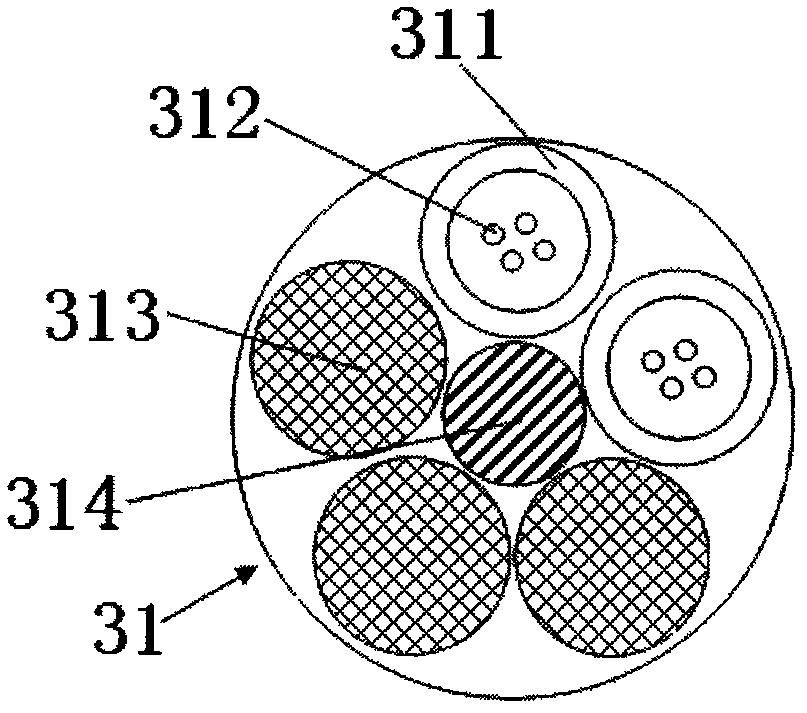

[0054] please see figure 1 and Figure 4 , and refer to figure 2 and image 3 , special-shaped cable 3, which is basically the same as the implementation example 1, except that the cable core is composed of a central strengthening member 314 at the center, a plurality of protective tubes 311 twisted around the central strengthening member, at least two insulated wires and The protective tube is composed of a filling rope 313, and the protective tube has at least one optical fiber 312; the insulated wire is composed of a conductor 316 inside and an insulating layer 315 covering the conductor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com