Electric shaver

An electric shaver and shaver technology, applied in the field of shaving tools, can solve the problems of poor portability and large size of electric shavers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

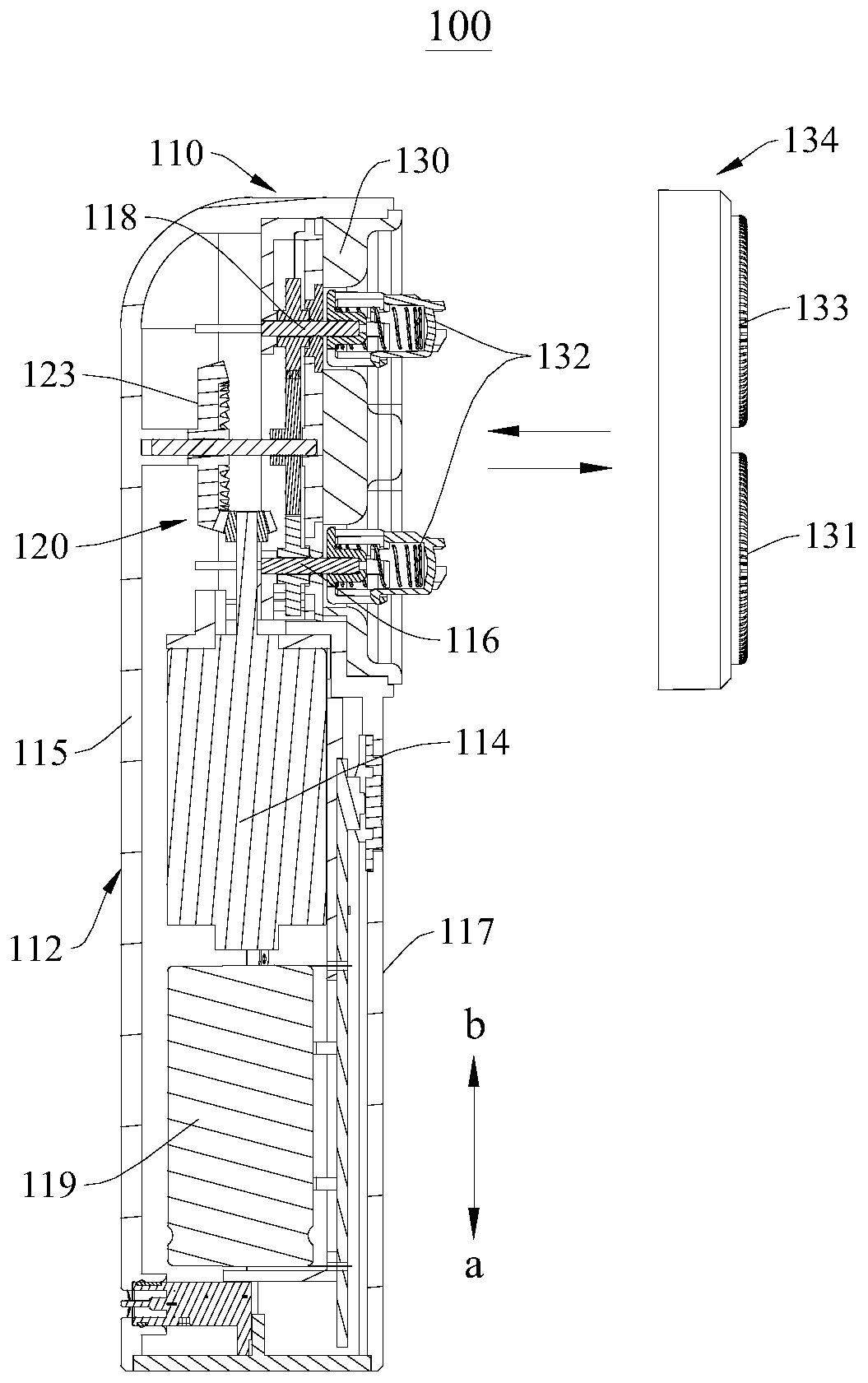

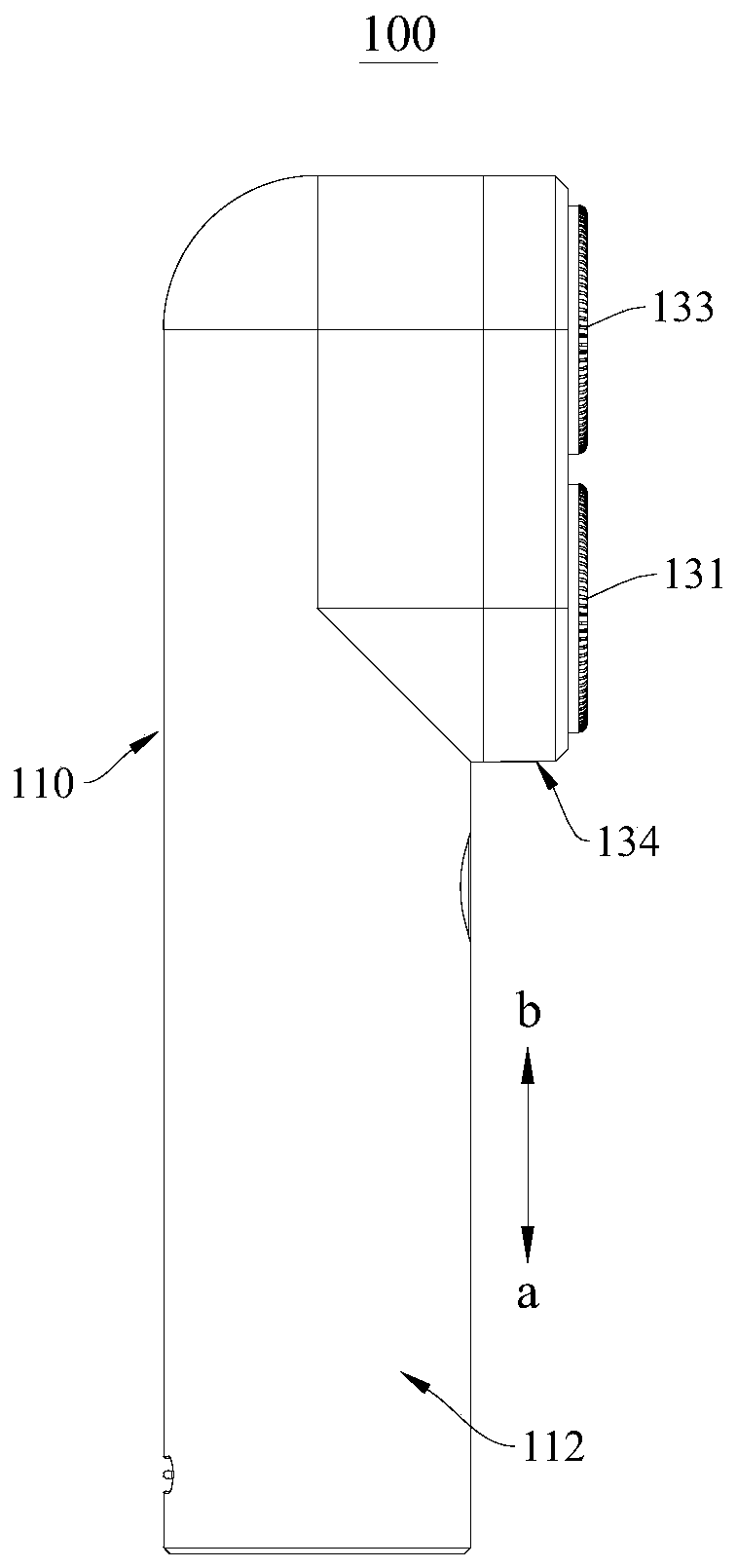

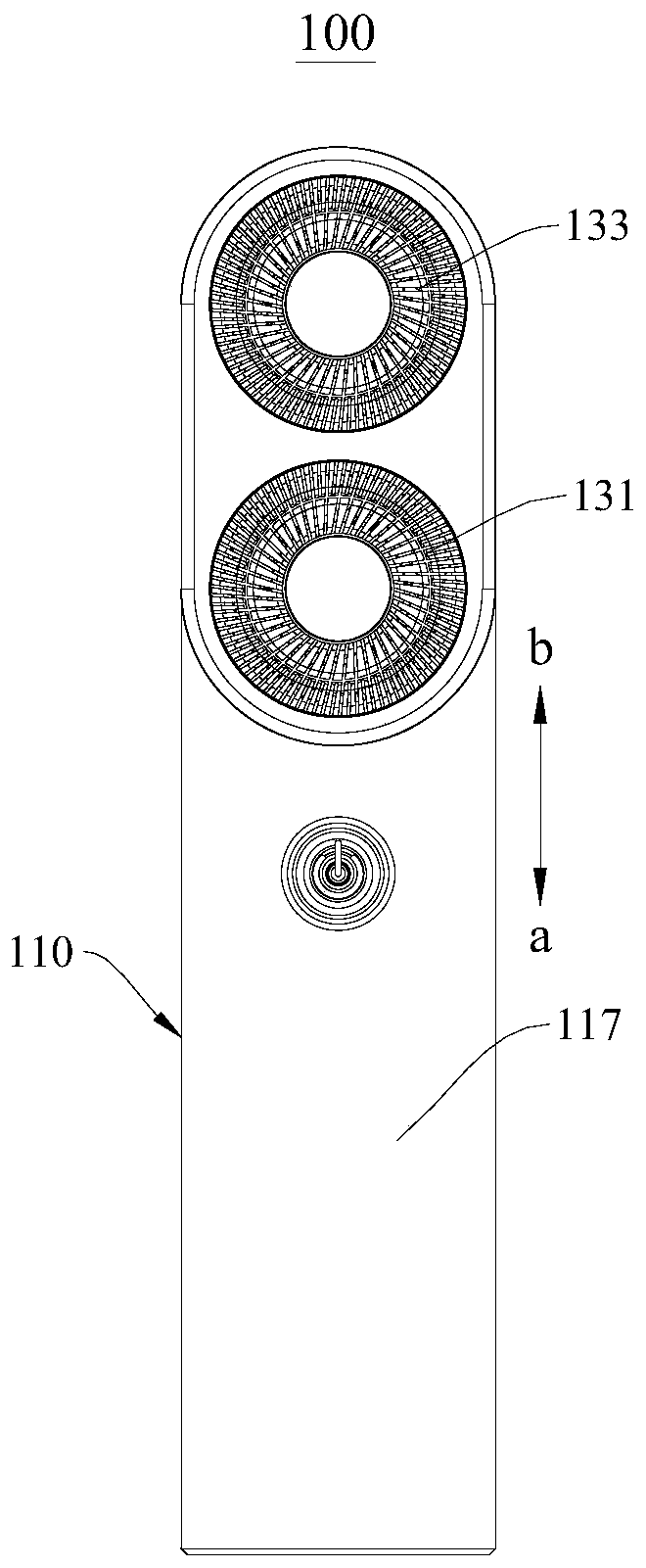

[0034] Please refer to figure 1 In order to reduce the peripheral size of the shaver to solve the above-mentioned portability problem, this embodiment provides an electric shaver 100, the electric shaver 100 includes a shaver body 110 and a first The first knife group and the second knife group. The shaver body 110 includes a housing 112 , a motor 114 disposed in the housing 112 , and a first rotating shaft 116 and a second rotating shaft 118 respectively rotatably connected to the housing 112 . The motor 114 is in drive connection with the first rotating shaft 116 and the second rotating shaft 118 at the same time, and the motor 114 is used to drive the first rotating shaft 116 and the second rotating shaft 118 to drive the first knife group and the second knife group to rotate respectively. The output shaft 113 of the motor 114 extends along the length direction of the casing 112 , and there are angles between the output shaft 113 of the motor 114 and the first rotating sha...

no. 2 example

[0050] This embodiment provides an electric shaver 100, its overall structure, working principle and achieved technical effects are basically the same as those of the first embodiment, the difference lies in:

[0051] The electric shaver 100 is a three-head shaver. At this time, on the basis of the structure of the electric shaver 100 in the first embodiment, the electric shaver 100 also includes a third cutter set assembled on the shaver body 110, and the cutter head assembly 134 also includes a third cutter net, The third knife net is used to cover the outside of the third knife group. Please refer to Figure 6 , The shaver body 110 further includes a third shaft 140 rotatably connected to the casing 112 . The motor 114 is in transmission connection with the third rotating shaft 140 for driving the third knife set to rotate.

[0052] In this embodiment, the output shaft 113 of the motor 114 and the third rotating shaft 140 are perpendicular to each other. In other embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com