A pull-off duplex dlc plug

A plug-and-join technology, applied in the field of pull-off duplex DLC plugs, can solve the problems of inconvenient removal and removal, and achieve the effect of solving the inconvenience of removal and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

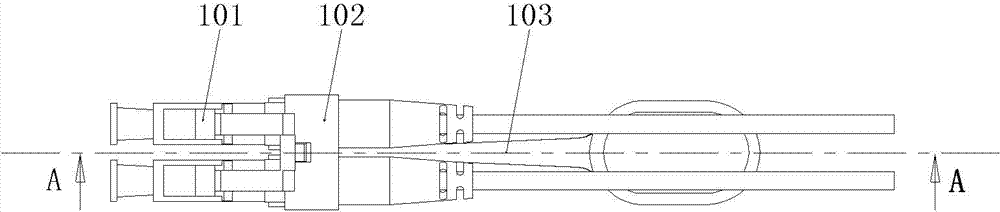

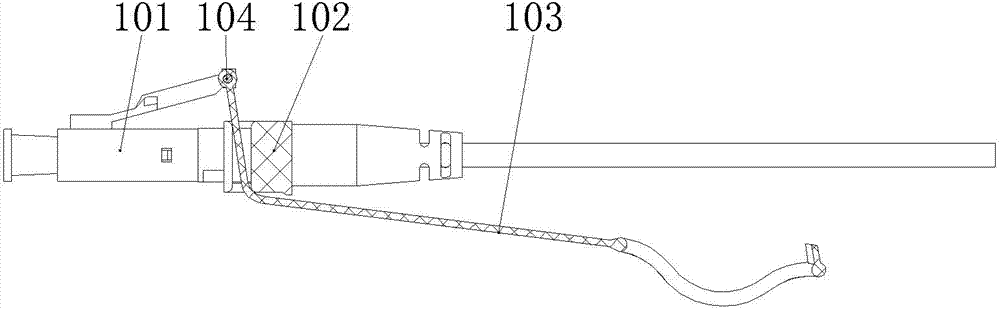

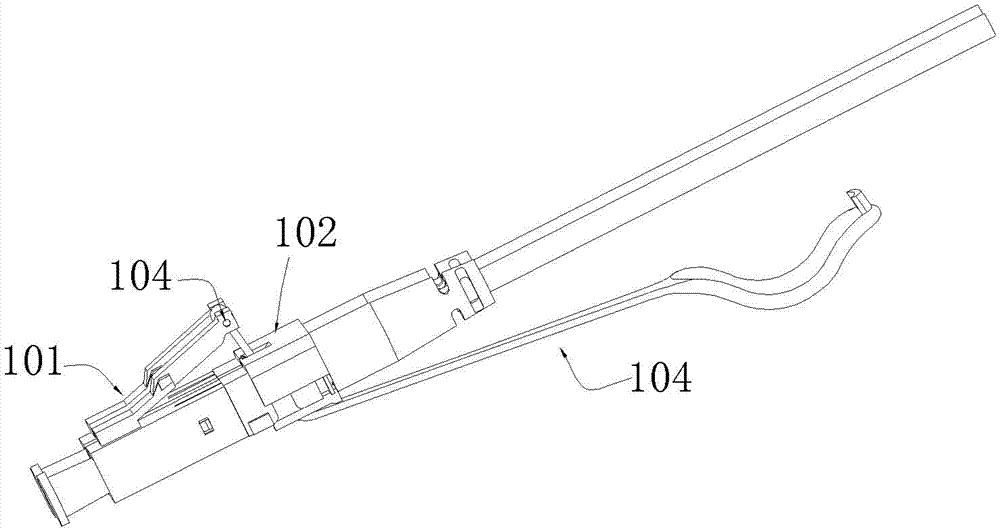

[0021] Pull-off duplex DLC plug embodiment 1 of the present invention, as Figure 1-8 As shown, it consists of two plug units 101 , a positioning housing 102 , a pull cord 103 and a cross bar 104 . The plug unit 101 includes an outer shell 11, a rear sleeve 12 and an optical contact (not shown in the figure) assembled in the outer shell 11. The rear end of the optical contact is connected with a tail cable 13, and the two plug units 101 The outer casings 11 are respectively provided with clips 11-1 on the top surface for clamping with the adapter sockets. The clips 11-1 are elastic, and their front ends are integrally fixed on the corresponding outer casings 11, and their axial ends extend backward and In the process of extending backward, it gradually inclines to the periphery (above) of the plug unit 101. There is a block 11-2 between the two ends of the clip 11-1. The clamping block 11-2 is fitted with an adapted socket; the positioning housing 102 includes a bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com