Novel sealing ring structure for stop valve

A technology of connecting sleeves and sealing rings, which is applied in the field of hydraulic components, can solve the problems of easy leakage of sealing rings and insufficient tightness of the structure, achieve good connection effect and overcome the effect of insufficient tight connection of connecting sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

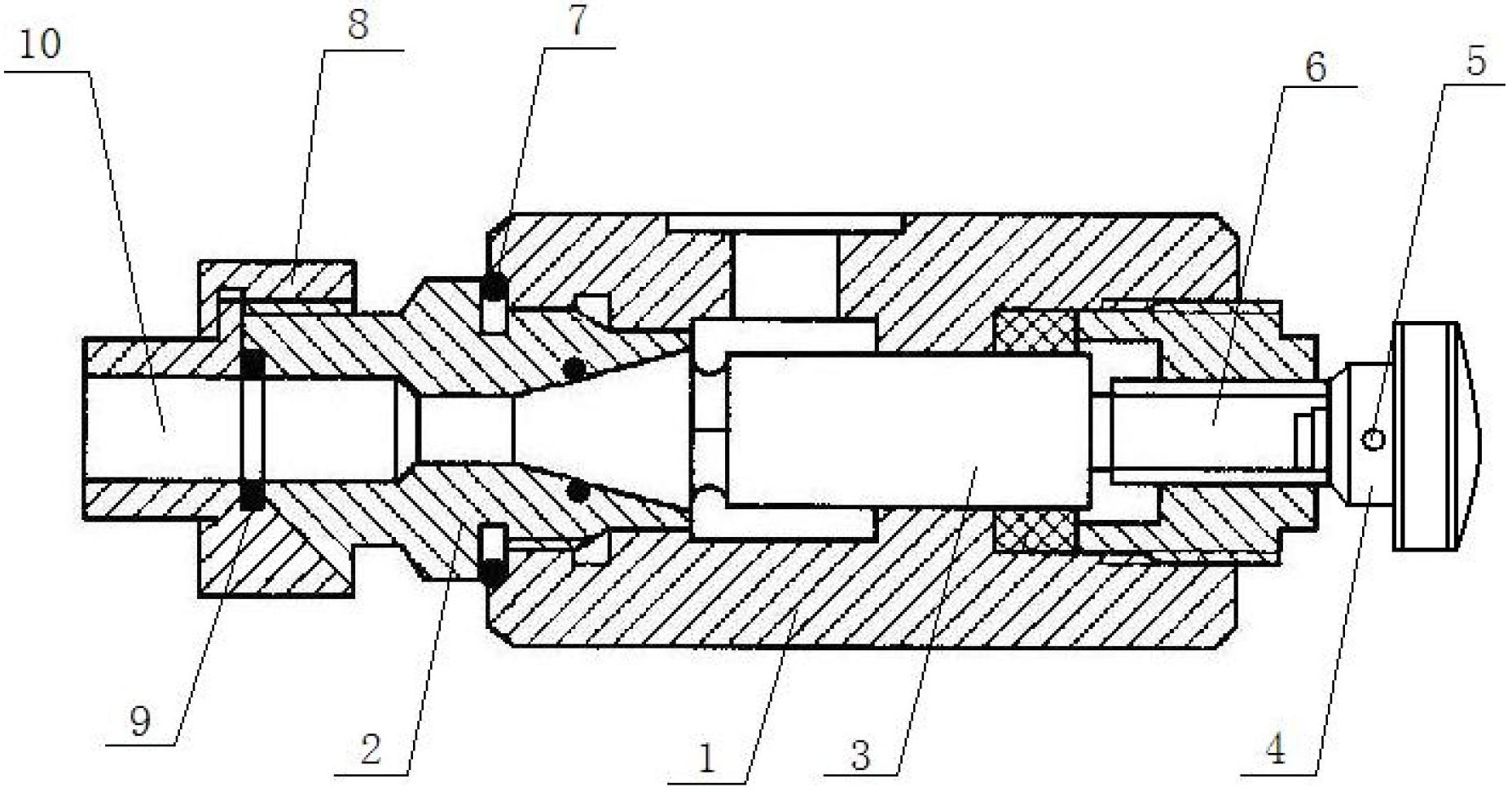

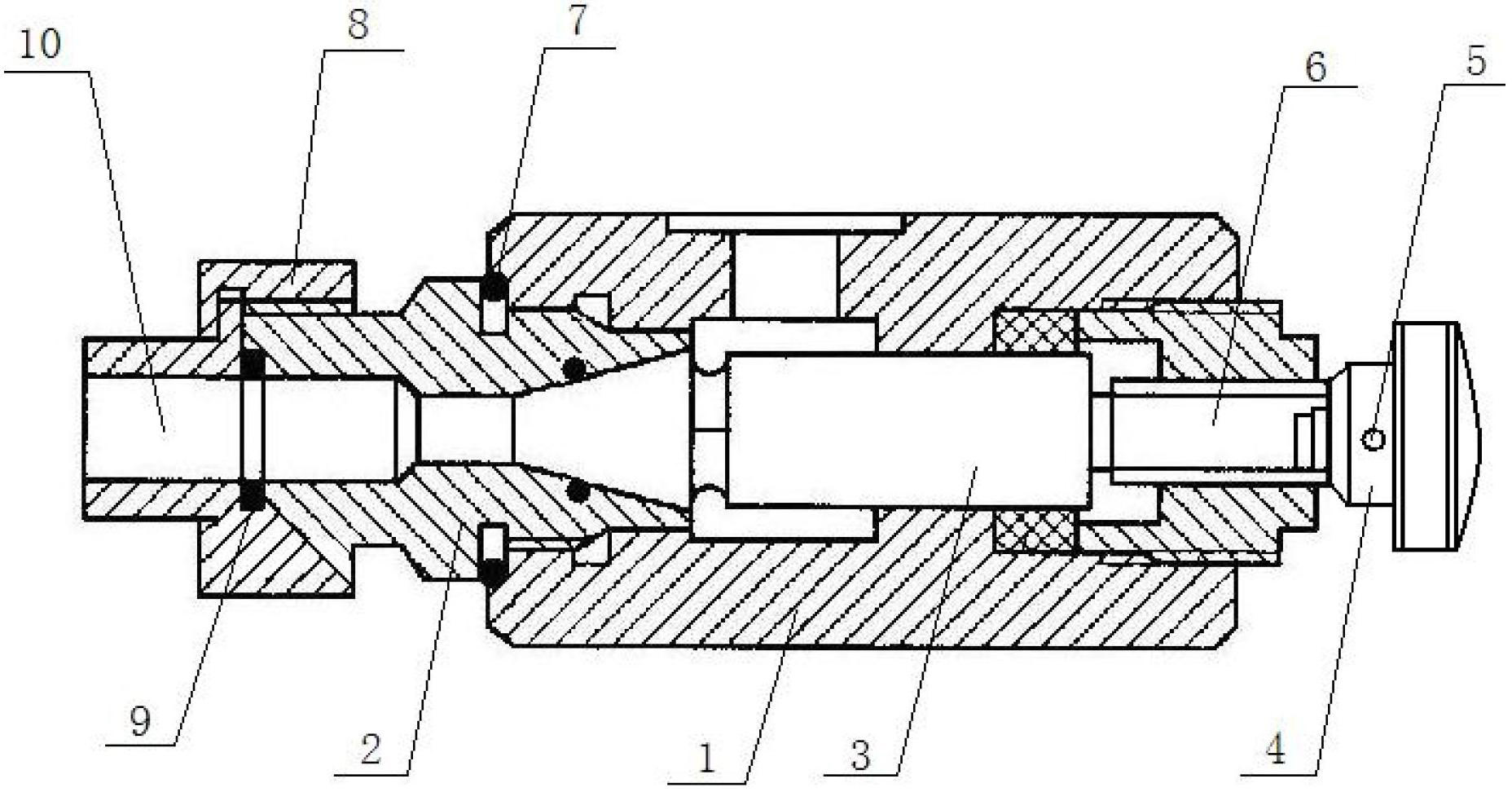

[0009] The sealing ring structure of the connecting sleeve has a valve body (1), a valve seat (2) is connected to the left side of the valve body (1), and a rear sealing ring (7) is arranged between the valve seat (2) and the valve body (1) Sealing; there is an adjustment wheel (4) at the rear end of the valve body (1), and the adjustment wheel (4) is installed on the right end of the valve core (3) through threaded pins (5) and threads (6); on the valve body (1) There is a connecting sleeve (10) on the valve seat (2) at the front end, and the connecting sleeve (10) is installed on the right end of the valve seat (2) through the coupling sleeve (8). A front sealing ring (9) is arranged between the sleeves (8) for sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com