Method for controlling liquid level of four-hold water tank based on phase plane method

A technology of liquid level control and four-capacity water tanks, which is applied in the direction of liquid level control, adaptive control, general control system, etc., and can solve the problem of high model dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

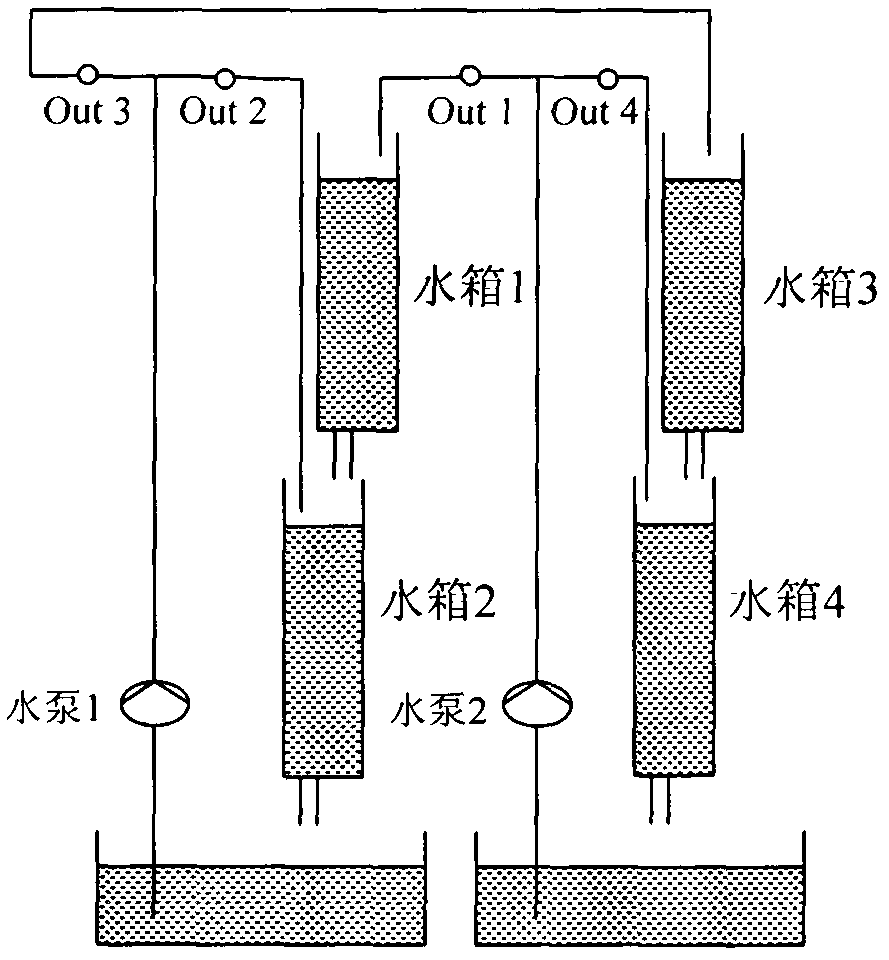

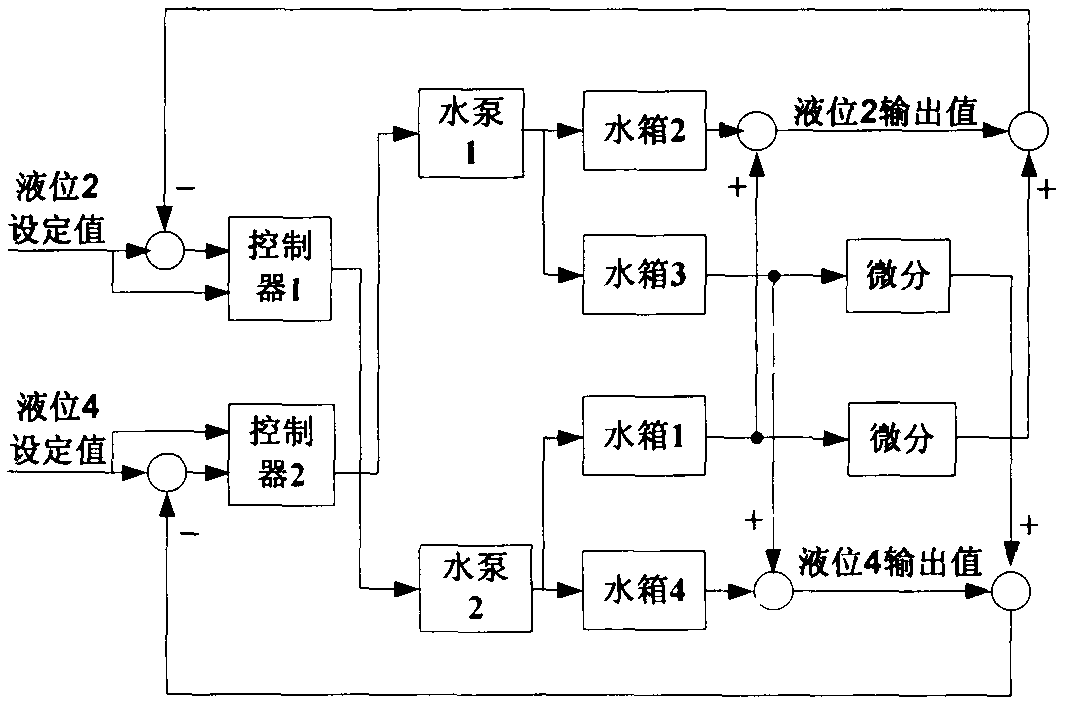

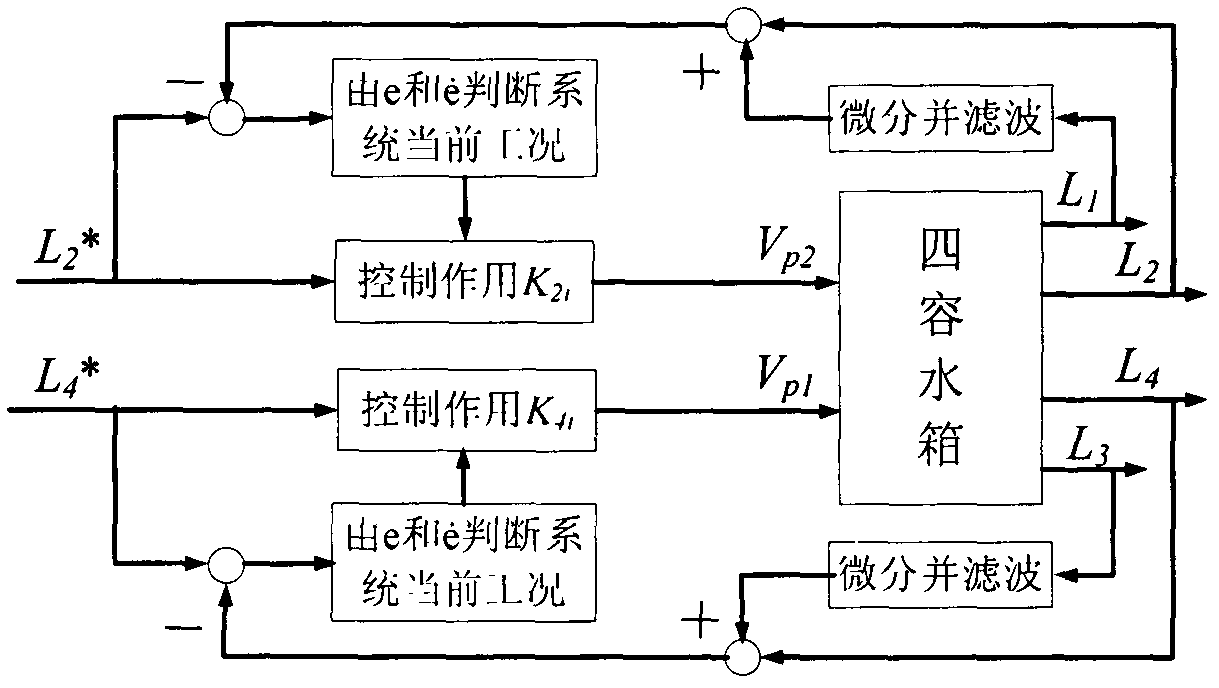

[0021] figure 1 Among them, "out1" to "out4" are four water outlets with adjustable pipe diameters. image 3 Middle V Pi (i=1, 2) is the voltage value output from the controller to the water pump. The liquid level in tank 2 is L 2 , the liquid level of tank 4 is L 4 . They are the liquid level setting values of tank 2 and tank 4 respectively. The liquid level of the upper water tank 1 is L 1 , the liquid level of tank 3 is L 3 . K 2i (i=0, 1±, 2±, 3±, 4±) means L 2 Nine open-loop gains of the loop controller, K 4i (i=0, 1±, 2±, 3±, 4±) means L 4 Nine open-loop gains for the loop controller.

[0022] Step 1: First find out two pairs of input and output combinations with relatively small coupling, and then use two controllers to control them separately. The following steps use one of the controllers as an example.

[0023] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com