Flat clinch type stapler

A stapler and nail foot technology, which is applied in the directions of staple staple tools, manufacturing tools, etc., can solve the problems of longitudinal bending of the through-end of the staples, guide of the staples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

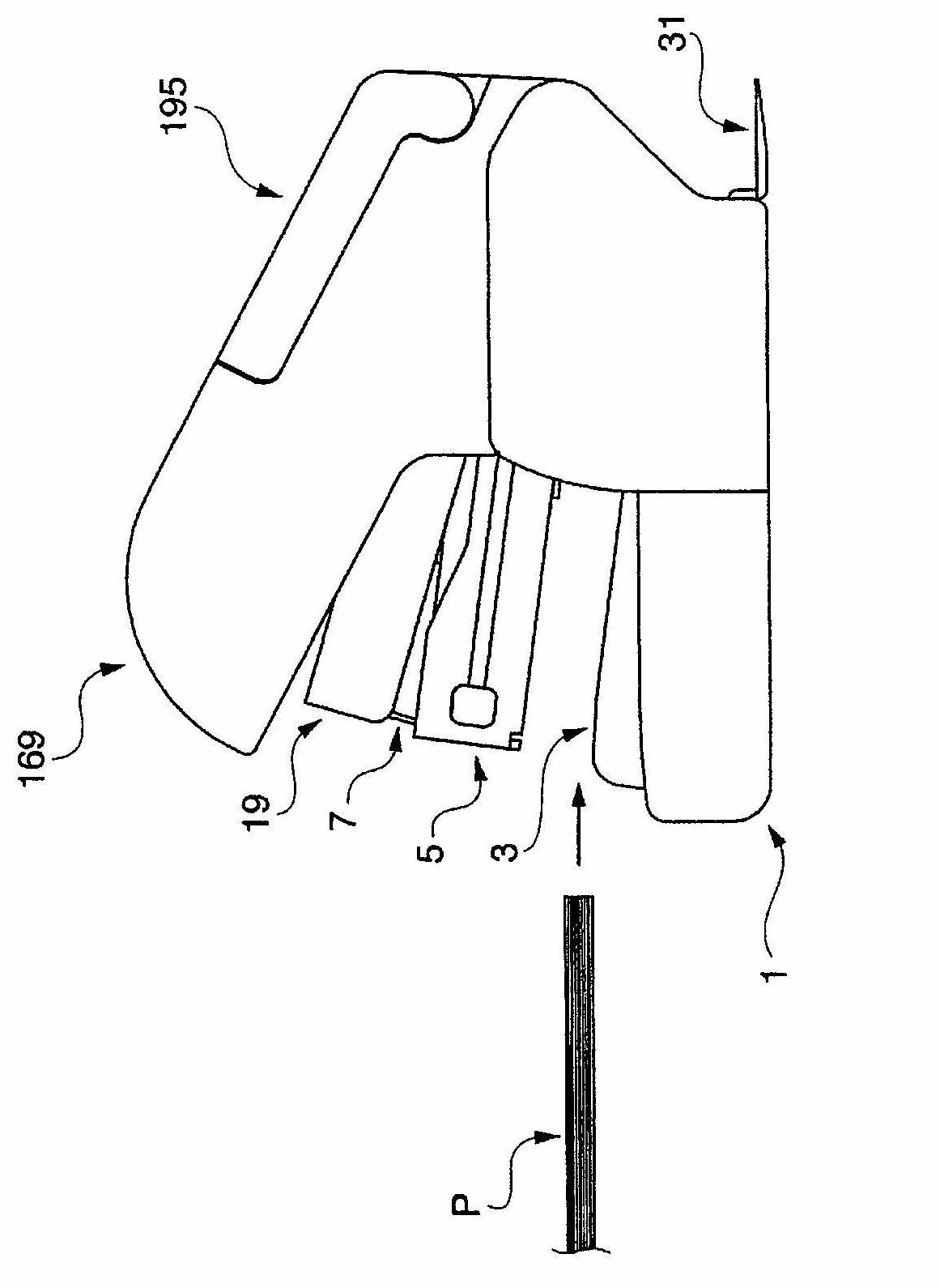

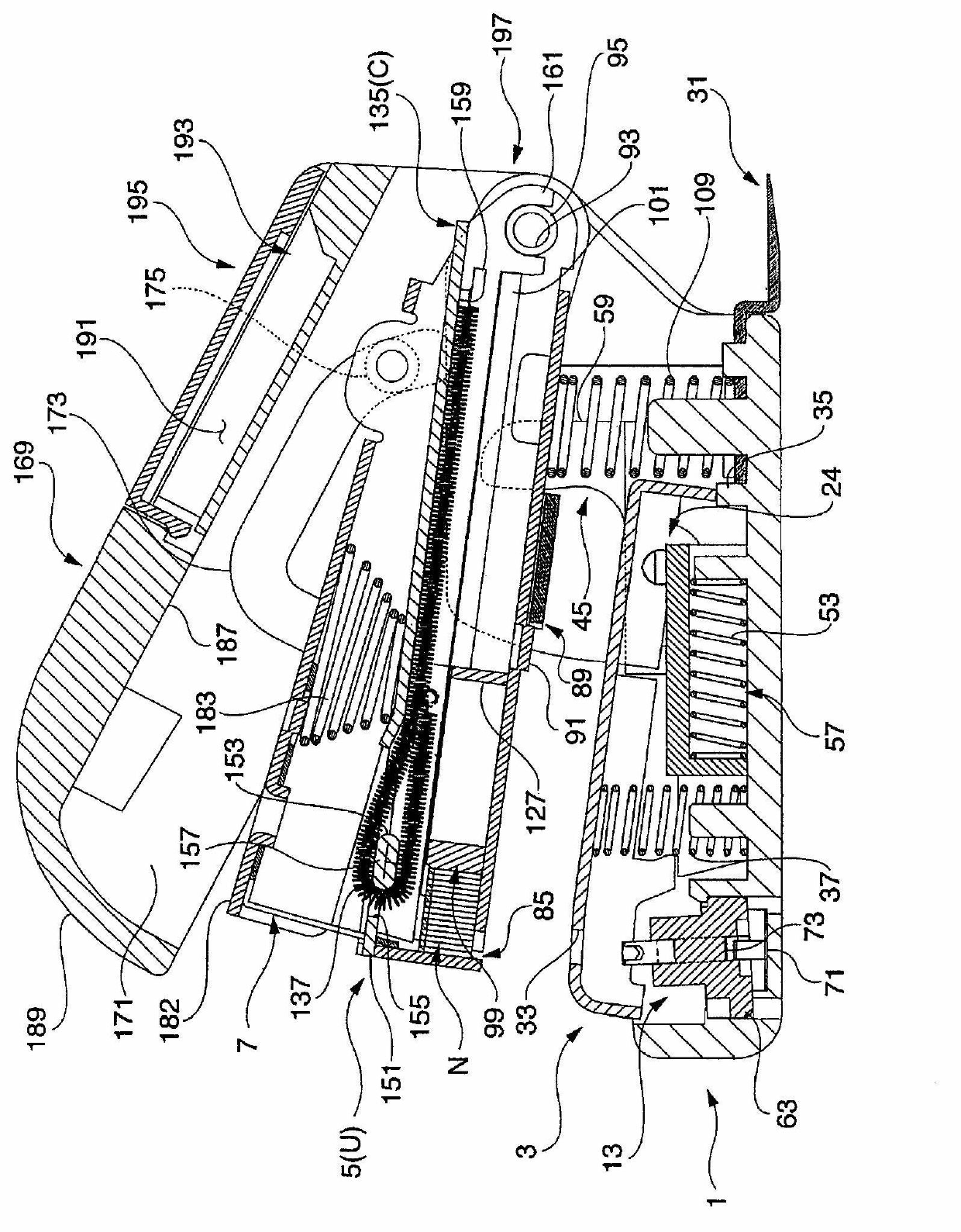

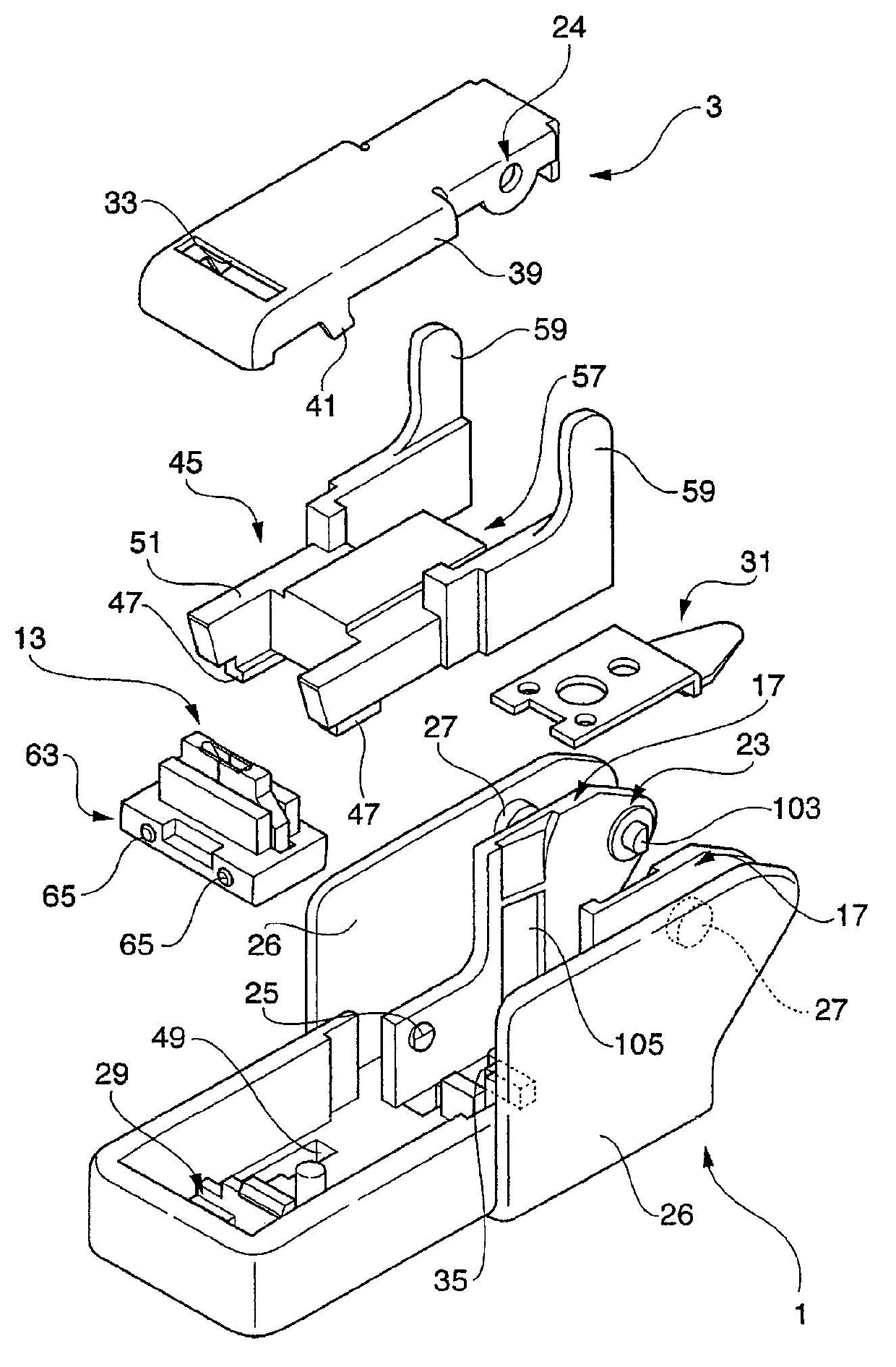

[0037] Below, while referring to the attached Figure 1 One embodiment of the present invention will be described.

[0038] The flat foot type stapler, such as Figure 1 to Figure 15 As shown, it has: a base 1; a paper loading table 3, which is pivotally connected to the base 1, and is used to add paper P to be bound; a staple box 5, which is arranged opposite to the paper loading table 3 and holds staples N; push knife 7, it pushes out the staple N held in the staple box 5 toward the paper carrier 3 direction; anvil 13, it is used to pass through the abutting surface 9 for bending or the abutting surface 11 for forming will be used by the abutting surface 11 The push knife 7 pushes out and bends the penetration end N1 of the staple N that has penetrated the paper P; After being engaged with the abutting surface 9 for bending, it is engaged with the abutting surface 11 for forming.

[0039] base 1 as Figure 1 to Figure 3 as well as Figure 5 As shown, it is molded by syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com