Suction cup

A suction cup and sealing area technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve problems such as shell damage and user injury, and achieve the effects of simple installation, improved operation, and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following description of the present invention, the same reference numerals indicate the same or comparable parts.

[0027] The features disclosed in the previous specification, claims and drawings are of great significance to the realization of different design solutions of the present invention not only individually but also in any combination.

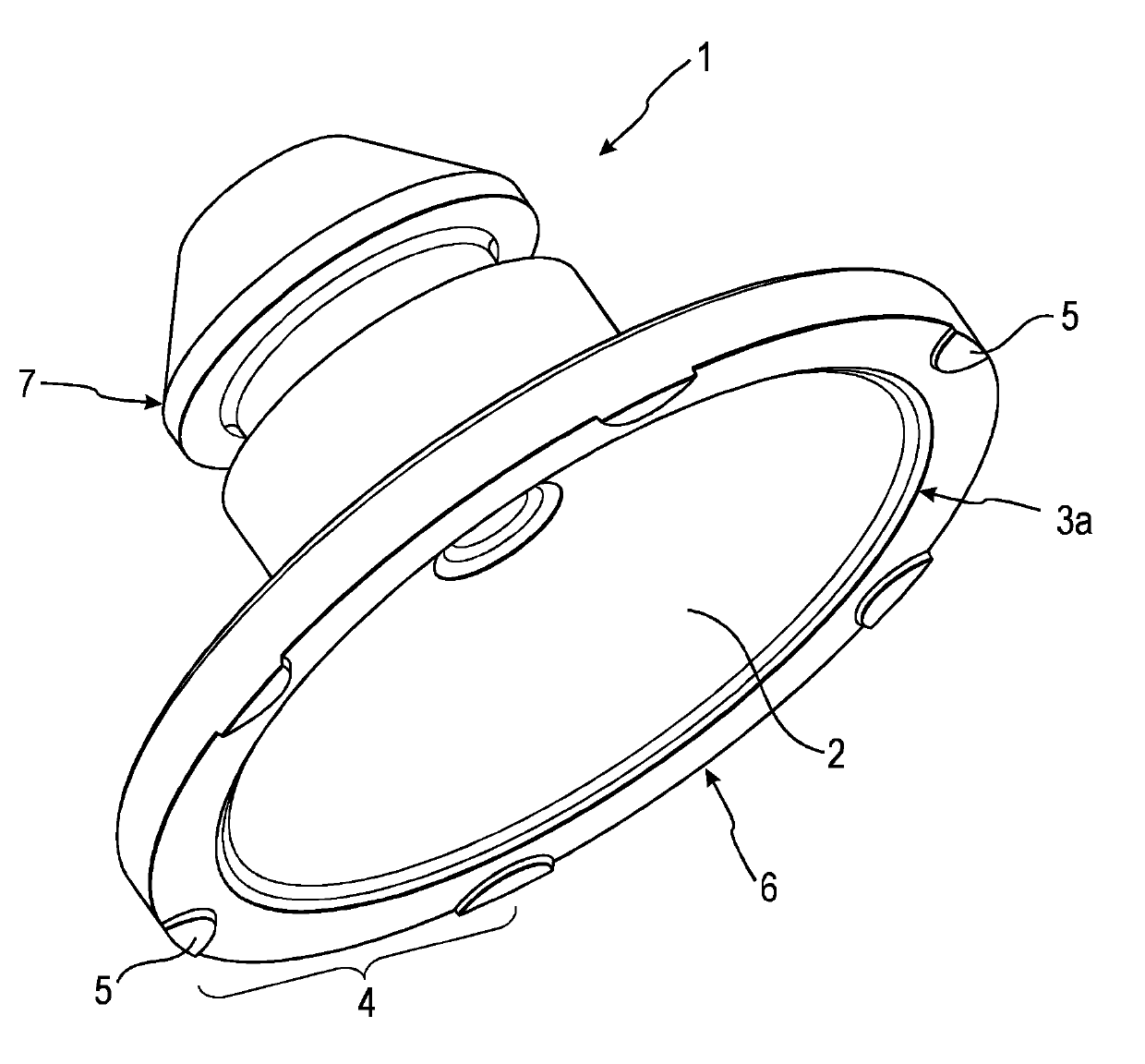

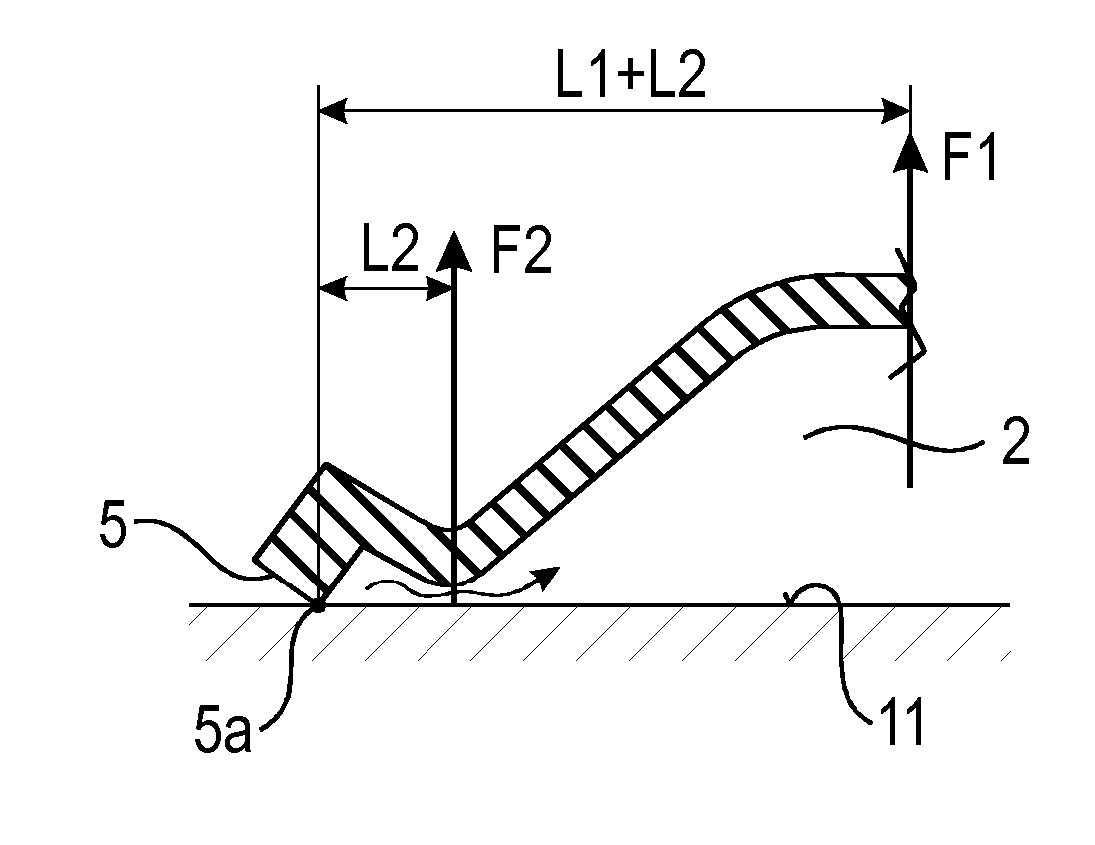

[0028] figure 1 A suction cup according to the invention is shown. The suction cup 1 includes a negative pressure chamber or suction housing 2 and a sealing area 3. The suction cup is usually pressed against the contact surface 11, and the air can escape from the negative pressure chamber by the applied pressing force. The suction cup 1 is made of an elastic-flexible material, especially rubber, so that the negative pressure chamber 2 can be deformed, so that air can be discharged. After the air escapes from the negative pressure chamber, a vacuum is formed, which can be maintained with respect to the environment by means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com