Gradually-peeling type passive peeling device for photocuring 3D printer

A technology of 3D printer and peeling device, which is applied in the field of 3D printing, can solve the problems that the resin layers cannot be lifted together, printing failure, etc., and achieve the effects of simple structure, reduced peeling force, and improved precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

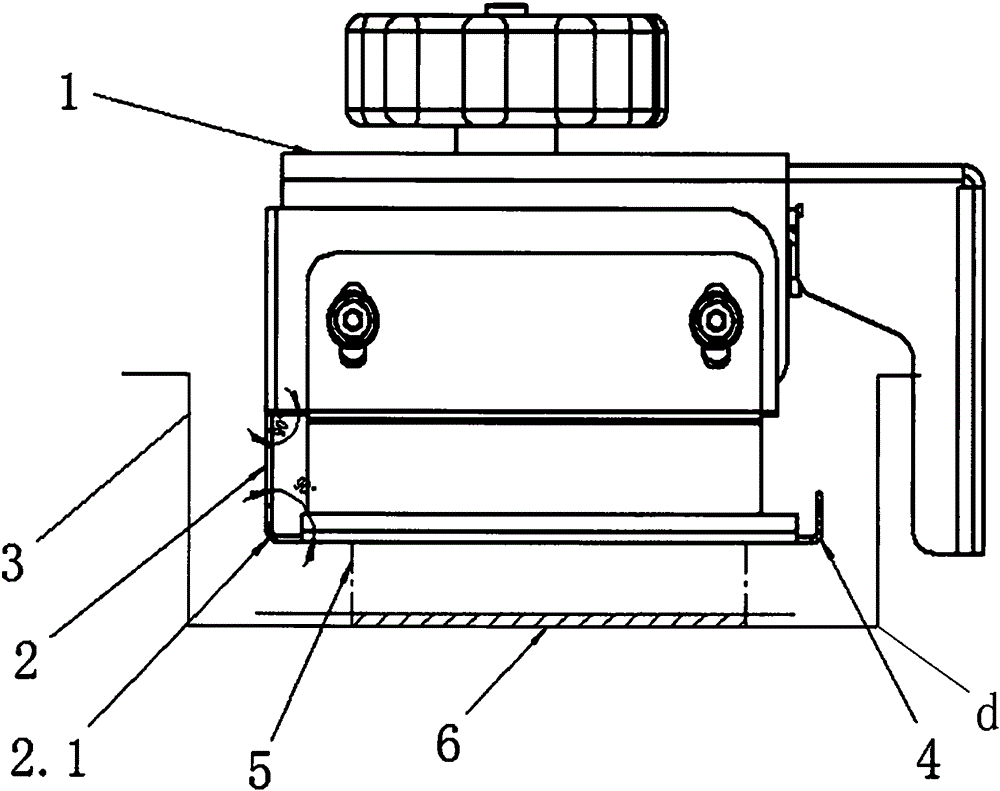

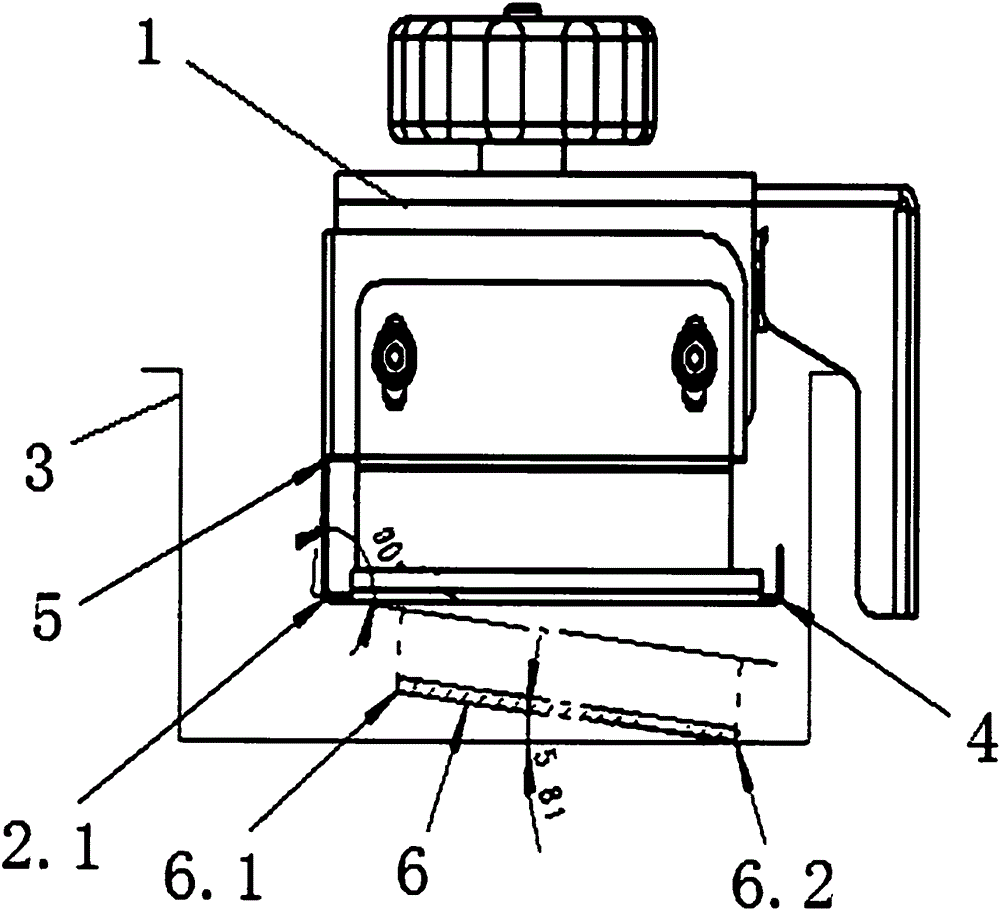

[0021] Embodiment 1: as figure 1 and figure 2 As shown, a light-curing 3D printer gradual-off passive peeling device provided by the present invention includes a printing head 1, and a resin tank 3 is correspondingly arranged under the printing head 1, and is matched with the lower side of the printing head 1. Connect a stripping device, the stripping device adopts the following structure, it includes an L-shaped printing tray 2, the knuckle 2.1 of the printing tray 2 is a right angle, and the end of a side wall of the printing tray 2 is connected to the printing tray 2. On the head 1, the other side wall is a cantilever structure. A flap 4 is provided at the end of the cantilever of the printing tray 2 . The printing tray 2 is made of carbon steel, which maintains good elasticity during long-term bending.

[0022] The L structure of the printing tray 2 utilizes the adhesion force to generate passive deformation, and reasonably converts surface contact peeling into line co...

Embodiment 2

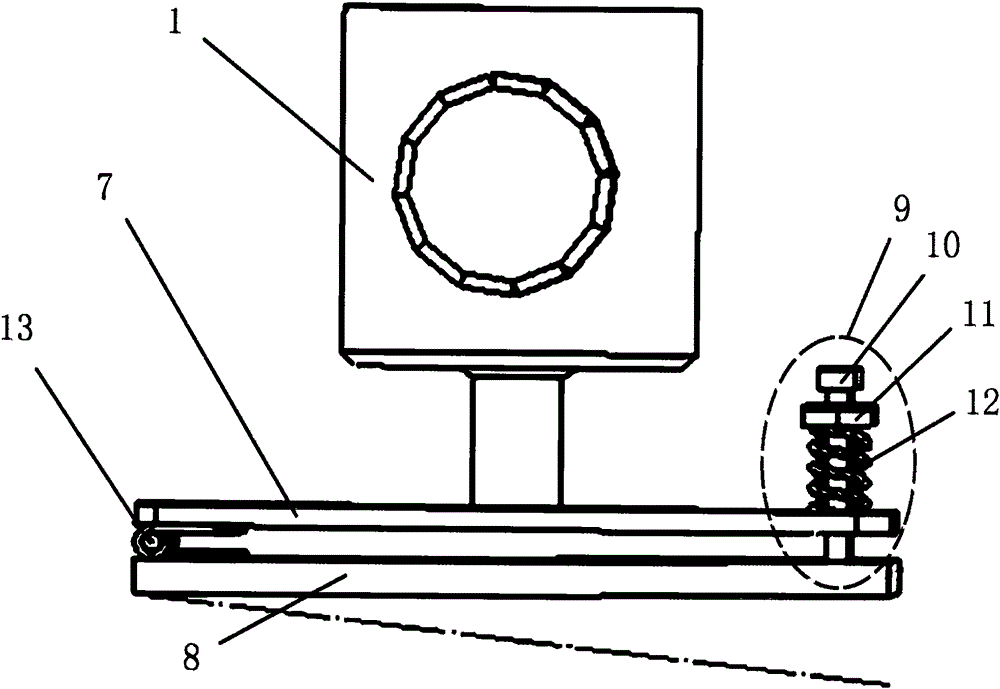

[0025] Example 2: Combining image 3 As shown, the peeling device in Embodiment 1 can also adopt the following structure, which includes a fixed plate 7 fixedly connected to the print head 1, and the peeling plate is hinged and fixed under one side of the fixed plate 7 through a hinge shaft 13 8, the stripping plate 8 can rotate around the hinge shaft 13, and the other side of the fixing plate 7 is movably connected to the other side of the stripping plate 8 through a reset device 9. The resetting device 9 includes a connecting rod 10 with one end fixed on the peeling plate 8, the connecting rod 10 passes through the fixing plate 7, and a stopper 11 is fixed on the connecting rod 10 on the fixing plate 7 upper side. A back-moving spring 12 is also socketed on the connecting rod 10, and the back-moving spring 12 is arranged between the fixed plate 7 and the block 11, and the back-moving spring 12 is always in a compressed state. The connecting rod 10 adopts a bolt, and the stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com