Weld detecting method and weld detecting apparatus

A detection method and weld area technology, which is applied in the field of weld area detection and weld area detection devices, can solve problems such as excessive time, and achieve the effect of reducing time spent and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

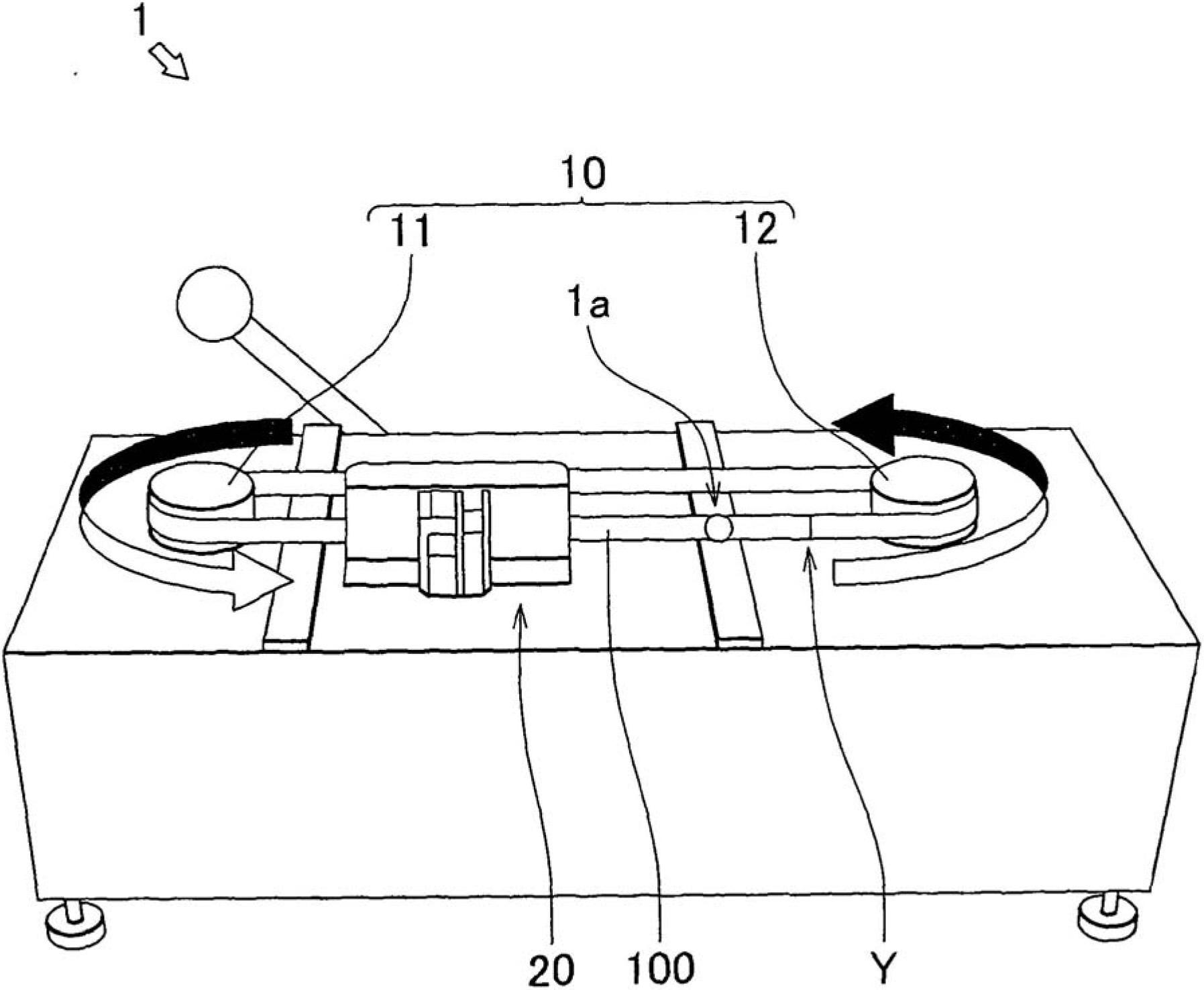

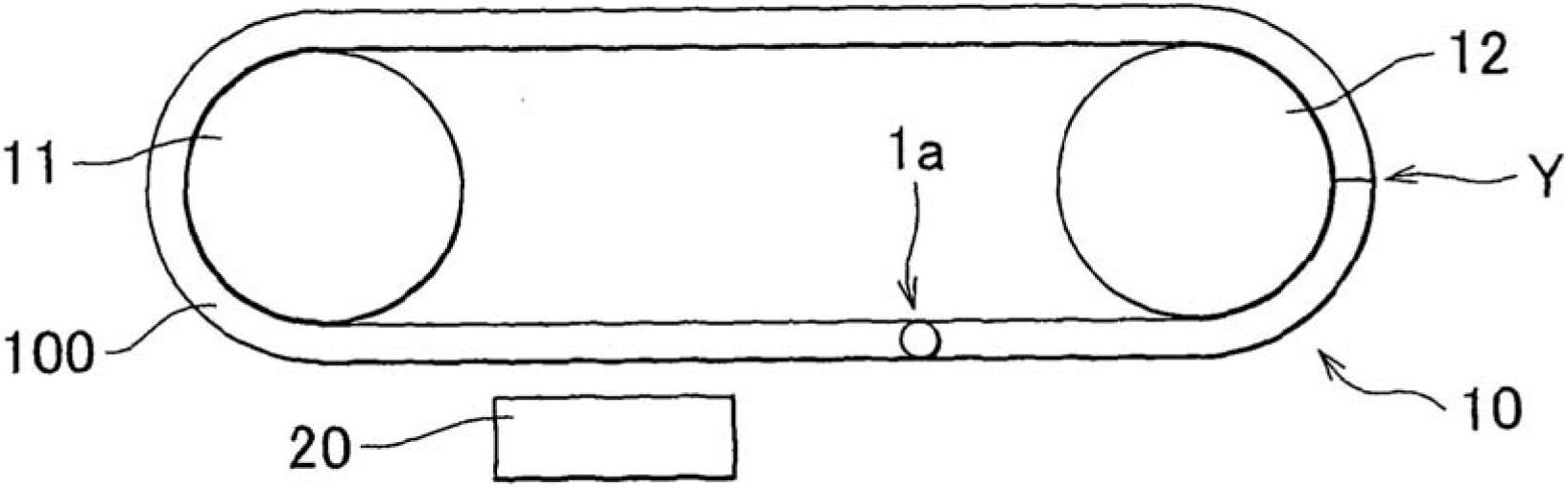

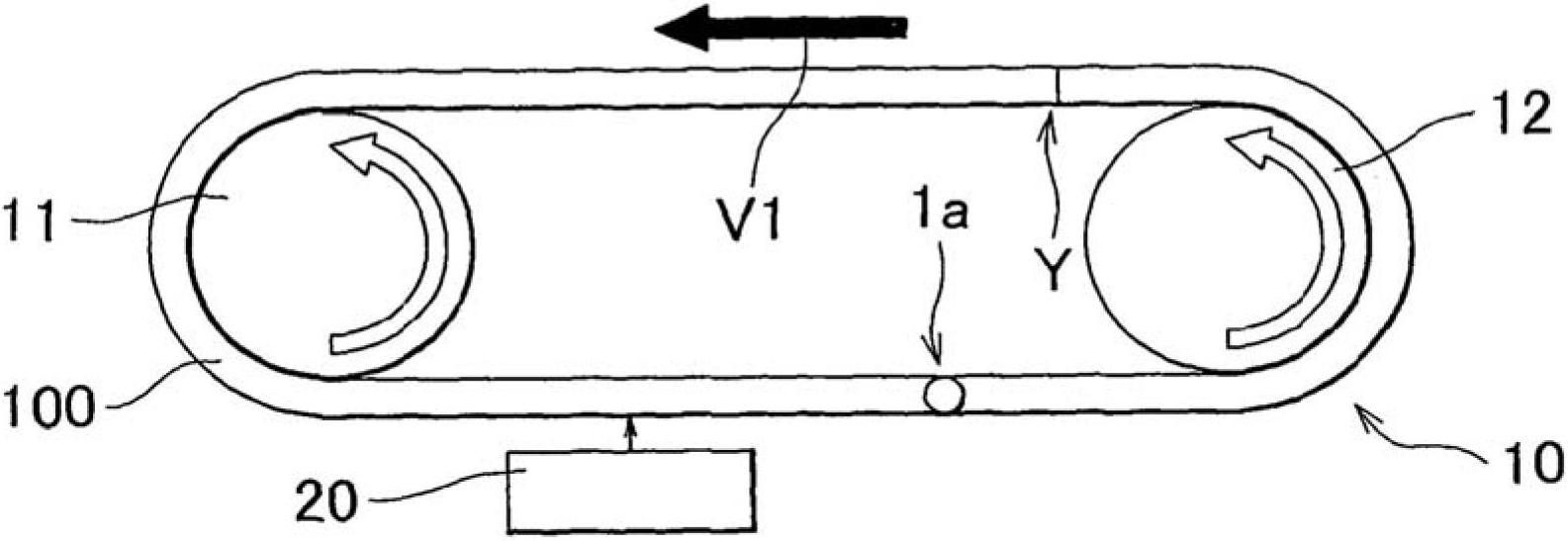

[0035] Hereinafter, a weld zone detection device 1 for detecting a weld zone Y using the weld zone detection method according to the first exemplary embodiment will be described with reference to the drawings.

[0036] Such as Figure 1 to Figure 10 As shown, the bead region detecting device 1 detects the bead region Y on the work that is elongated after being welded by performing rolling, circumferential adjustment, etc. after welding. Some examples of such workpieces 100 are: a metal ring in which both ends of a band-shaped metal plate have been joined together by welding; and a joined metal strip in which ends of a plurality of band-shaped metal plates have been joined together by welding.

[0037] Incidentally, when detecting a weld zone on a workpiece formed in a ring shape such as a metal ring, the weld zone detecting device 1 structure is different.

[0038] Hereinafter, explanation will be given of the weld zone detecting device 1 when detecting the weld zone Y on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com