Water sprinkling device of plant cultivation machine

A technology of sprinkler and cultivator, applied in cultivation, soilless cultivation, botanical equipment and methods, etc., can solve the problem that water droplets cannot reach plants in the distance, the water lifting height and amount are low, and the water level difference of the water platform is small. and other problems, to avoid uneven watering, increase the water lifting height, and improve the water lifting height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

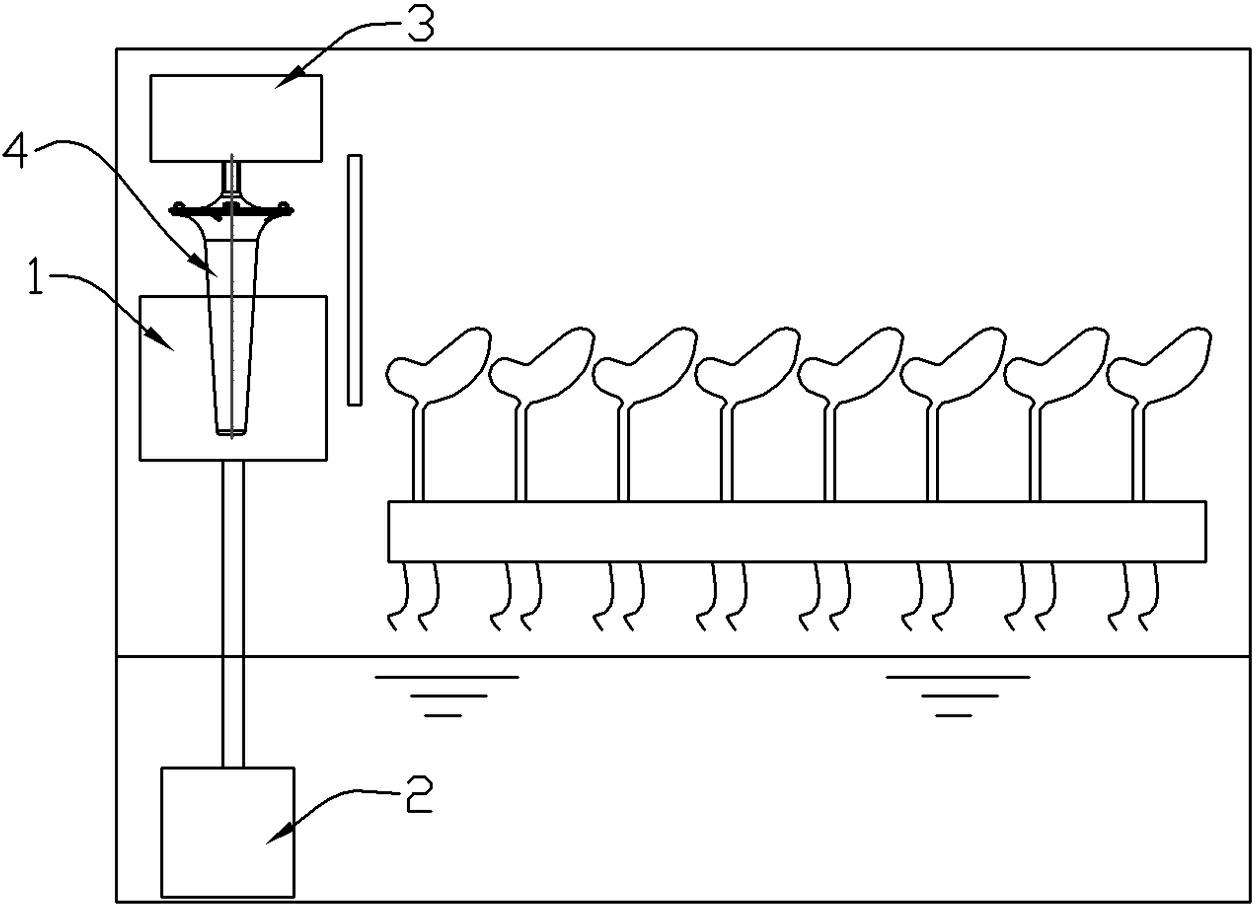

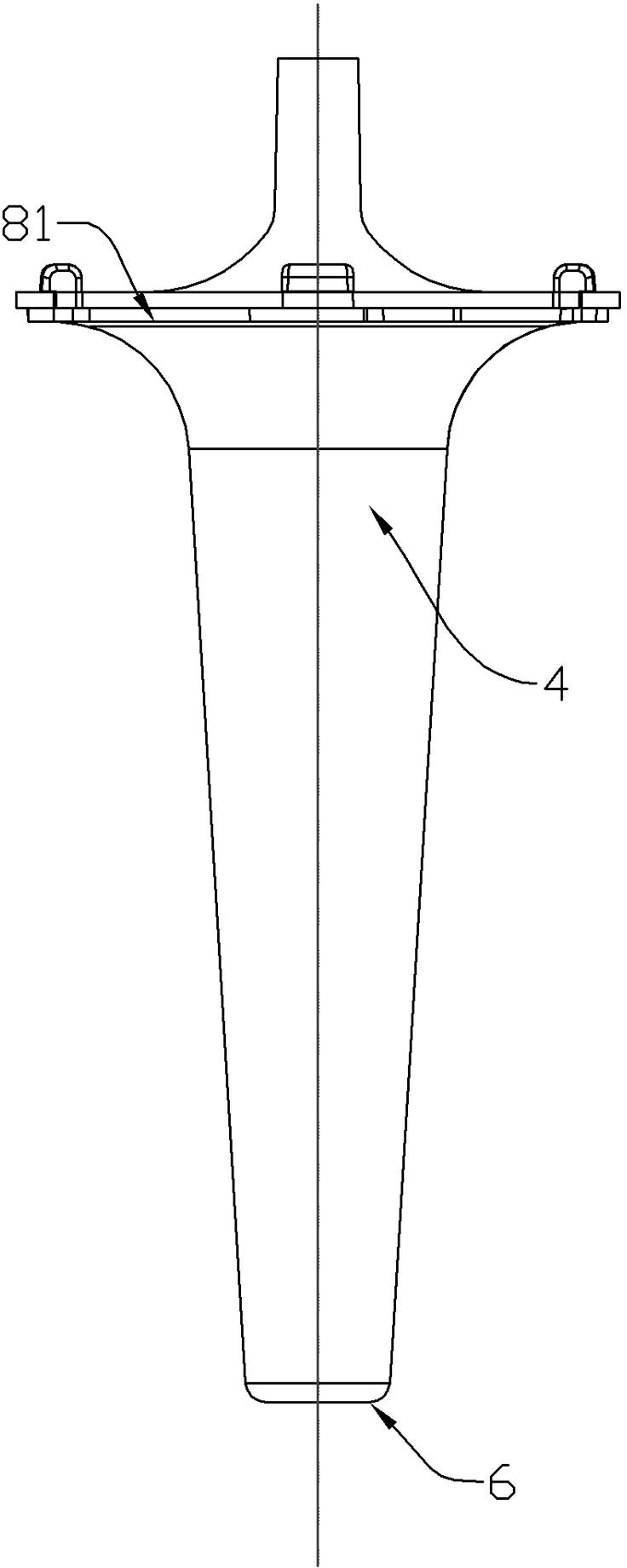

[0017] Example 1, such as figure 2 , The water pump 2 pumps water into the water-carrying platform 1, the cone of the cone 4 is downward and the bottom of the cone is upward, and the cone is inserted under the water surface of the water-carrying platform, and the motor 3 drives the cone to rotate. The cone 4 is provided with a water diversion cavity 5 on the shaft, and the bottom of the water diversion cavity communicates with the cone tip 6 of the cone. The cone tip 6 is provided with a blade 7 that can push water upward into the water diversion cavity 5 when rotating, such as Figure 7 , Picture 9 , There is a sprinkler hole 81 between the cone bottom and the side wall of the cone, and the upper part of the water diversion cavity communicates with the sprinkler hole 81, such as Figure 4 , When the cone rotates, the water in the water diversion cavity can be thrown out through the sprinkler hole.

[0018] When working, the water in the water-carrying container can flow up along...

Embodiment 2

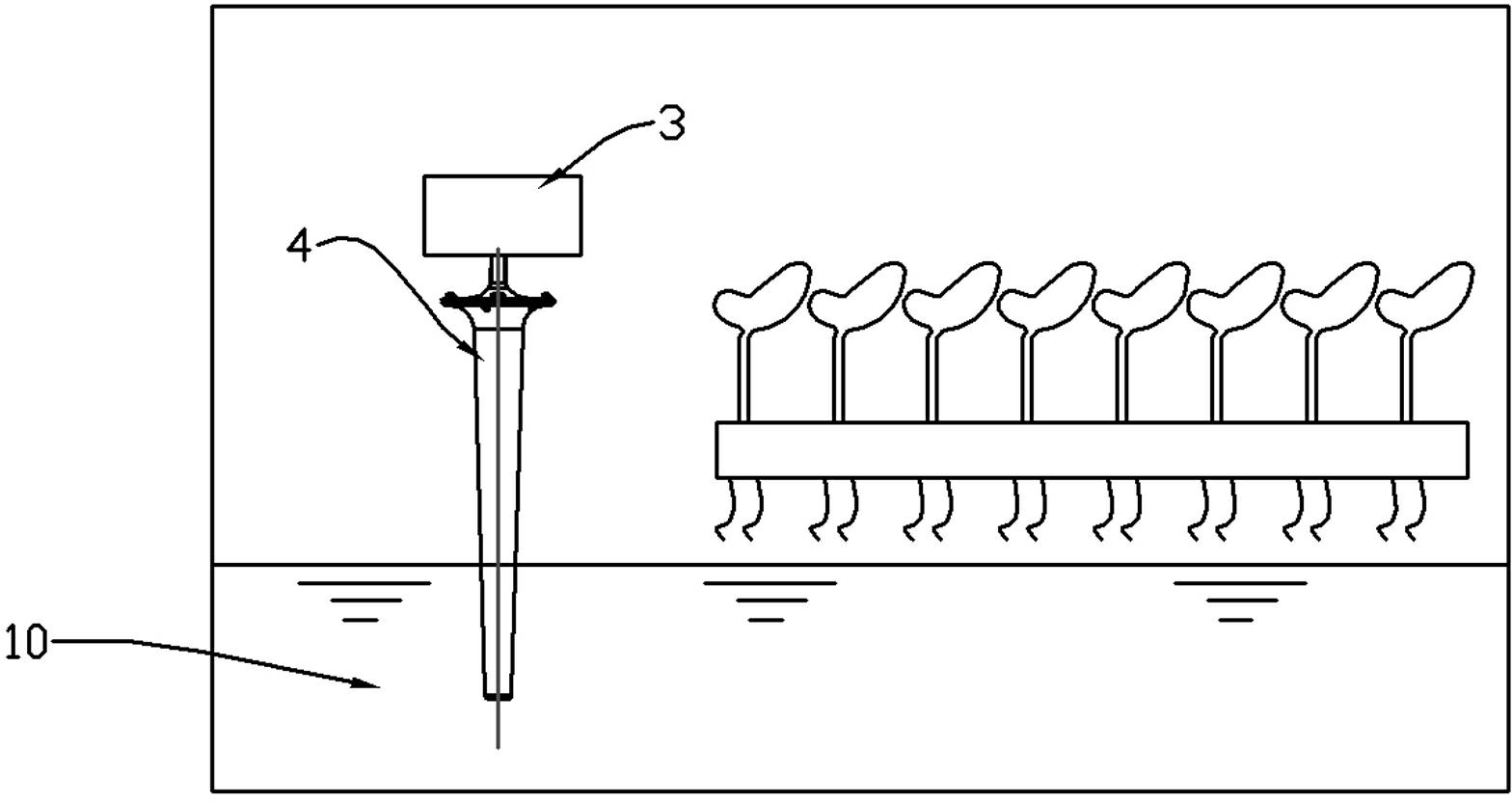

[0019] Example 2, such as image 3 The cone tip of the cone 4 is downward and the cone bottom is upward. The cone tip is directly inserted into the water-carrying container 10 and driven by the motor 3 to rotate. The cone 4 is provided with a water diversion cavity 5 on the shaft. The bottom of the water diversion cavity and the cone The cone tip part 6 is connected, and the cone tip part 6 is provided with a blade 7 that can push water upward into the water diversion cavity 5 when rotating, such as Figure 7 , Picture 9 , There is a sprinkler hole 81 between the cone bottom and the side wall of the cone, and the upper part of the water diversion cavity communicates with the sprinkler hole 81, such as Figure 4 , When the cone rotates, the water in the water diversion cavity can be thrown out through the sprinkler hole.

[0020] In the above embodiment, the cone 4 can also be provided with sprinkler holes 82 on the side wall near the bottom of the cone at the same time, communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com