Drill chuck for perpendicularly drilling holes

A technology of drill chucks and drill clamps, which is applied to drilling/drilling equipment, parts of boring machines/drilling machines, chucks, etc., which can solve the problems of increasing product costs and achieve the effect of improving balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

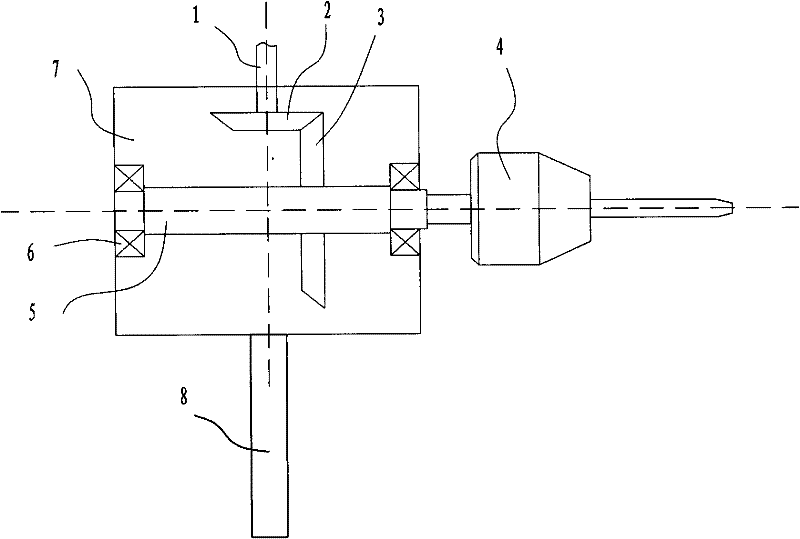

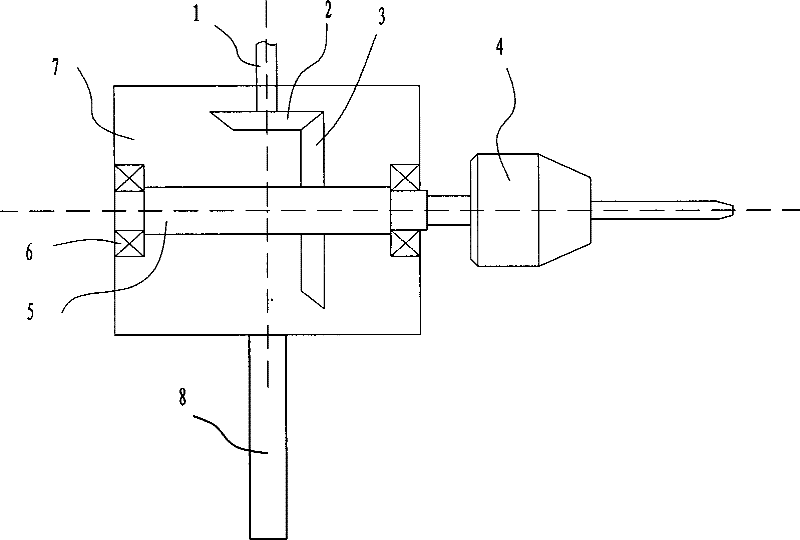

[0009] The invention is like figure 1 As shown, the drill bit clamp 4, the box body 7, the input shaft 1, the output shaft 5, the bevel gear one 2 and the bevel gear two 3 are included. The input shaft 1 and the output shaft 5 are respectively connected to the box body 7 through a bearing 6. They are at an angle of 90° with each other; the bevel gear-2 is fixedly connected to the shaft end of the input shaft 1, the bevel gear-2 is fixedly connected to the middle of the output shaft 5, the bevel gear-2 and the bevel gear-2 3 are engaged with each other; one end of the output shaft 1 extends out of the box body 7, and the end of one end out of the box body 7 is detachably connected to the drill clamp 4.

[0010] The outer wall of the box body 7 is also provided with a handle 8 which is arranged on the opposite surface of the connecting surface of the box body 7 where the input shaft 1 is located.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com