Bidirectional flexible fixture

A technology of flexible fixtures and fixtures, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problem that the fixture is difficult to clamp the workpiece, and achieve the effect of easier clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following examples are only used to illustrate the technical solutions of the present invention.

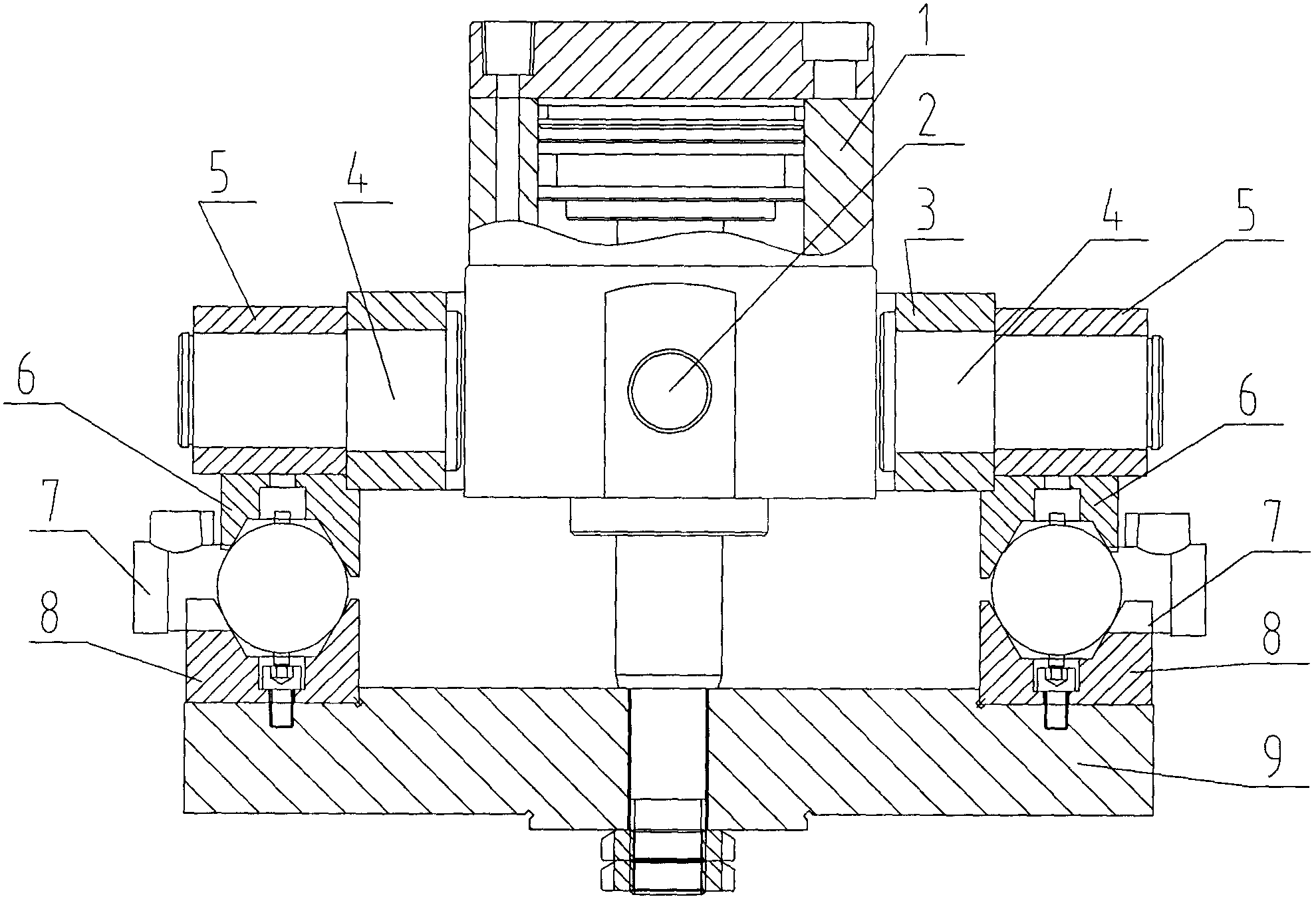

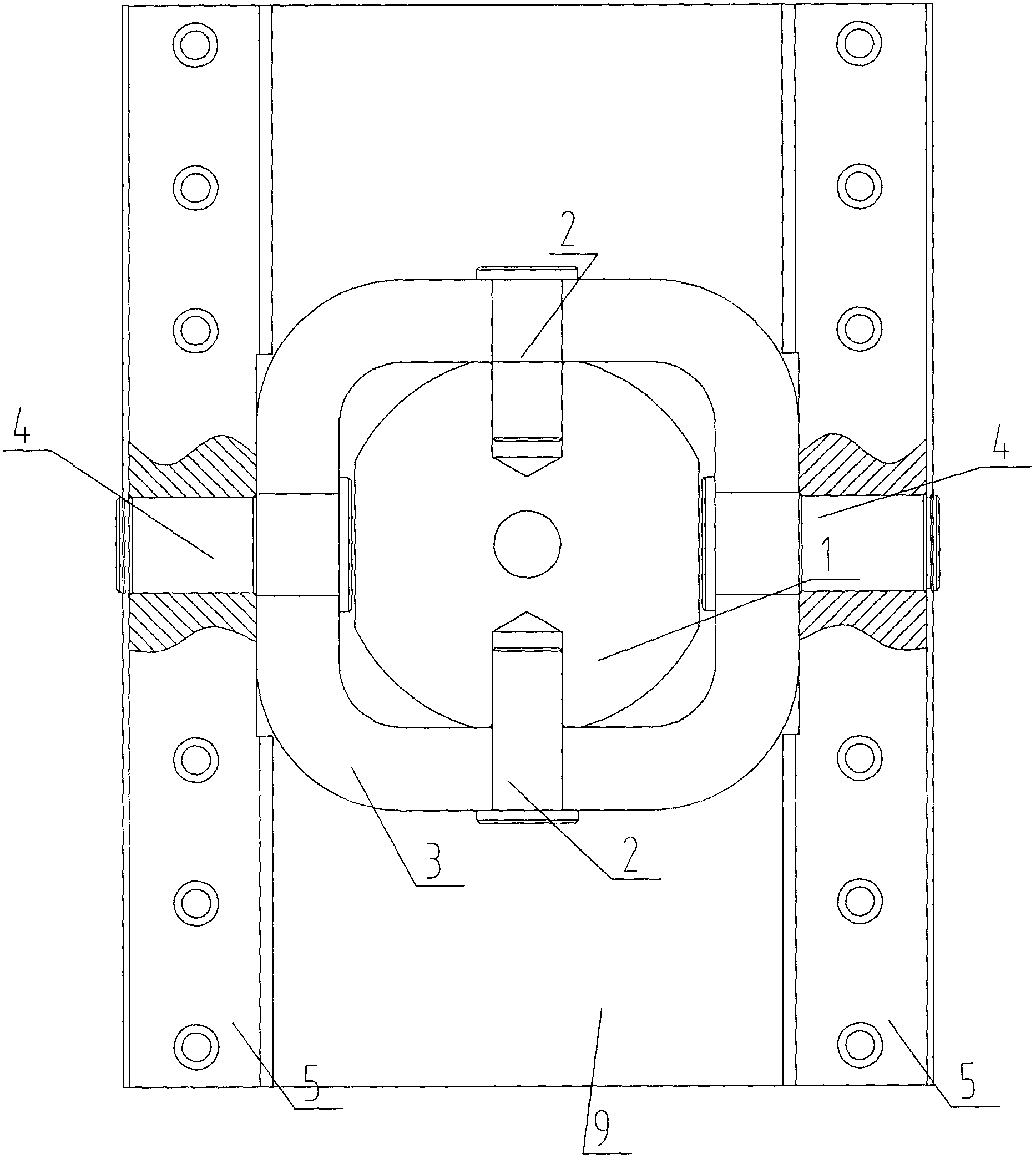

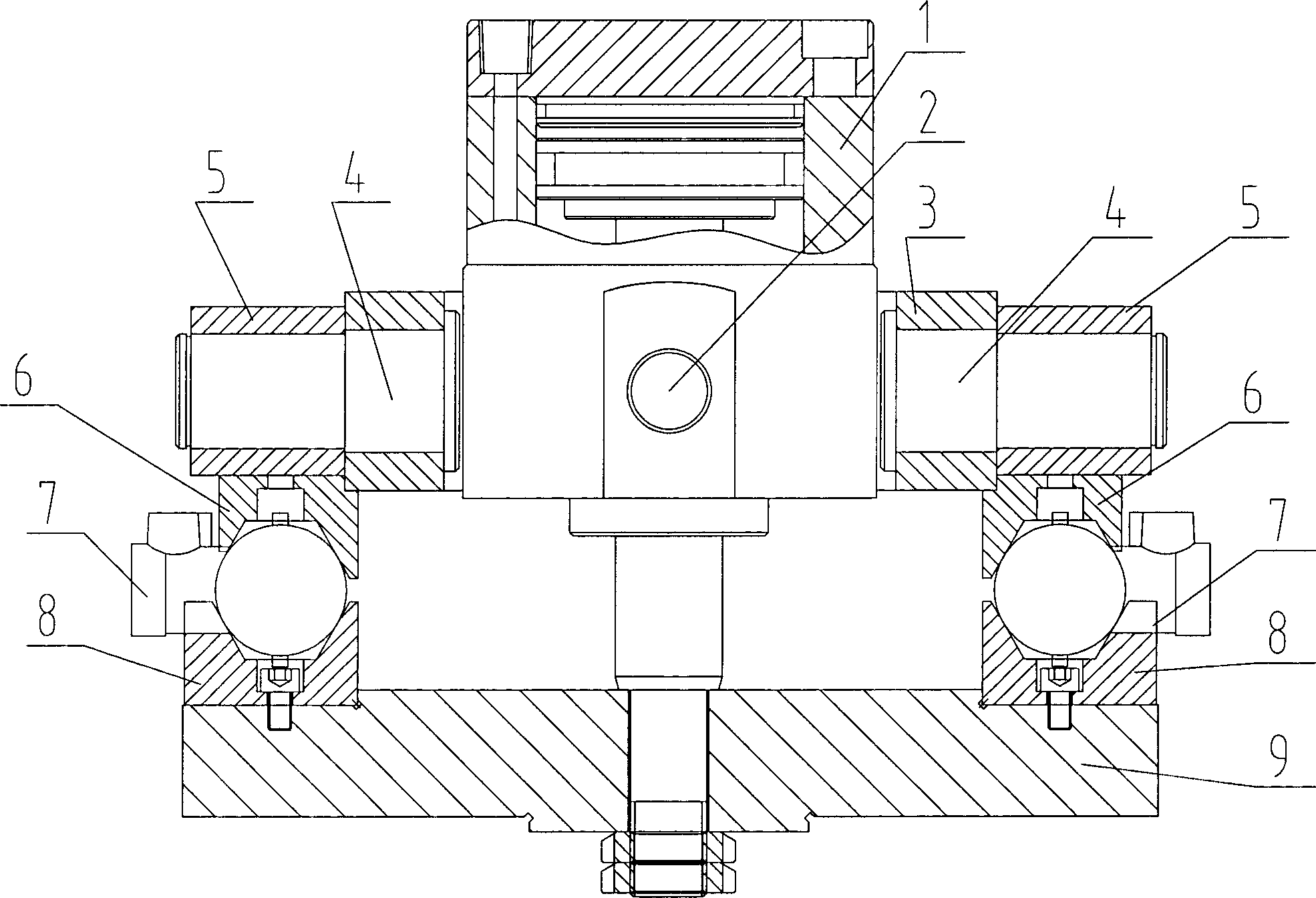

[0009] The two-way flexible fixture is characterized in that it includes an oil cylinder 1, a vertical pin 2, a swing ring 3, a horizontal pin 4, an upper fixture seat 5, an upper fixture 6, a lower fixture 8, and a bottom plate 9. The oil cylinder 1 is equipped with a swing ring 3, The upper fixture seat 5 is installed on the outer two opposite sides of the swing ring 3, the vertical pin 2 makes the oil cylinder 1 and the swing ring 3 become movably connected, the horizontal pin 4 makes the swing ring 3 and the upper fixture seat 5 become movably connected; the upper fixture seat 5 An upper clamp 6 is fixedly installed, and a lower clamp 8 is installed under the upper clamp 6, and the lower clamp 8 is fixedly mounted on the bottom plate 9 below it. During work, the workpiece 7 is installed between the upper clamp 6 and the lower clamp 8, and the lifting cylinder 1 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com