Pressure plate mechanism used for packing machine

A technology of pressing boards and wood boards, applied in the field of packaging equipment, can solve the problems of unfixable, heavy weight, and low transportation efficiency, and achieve the effect of easy fixing, easy implementation, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

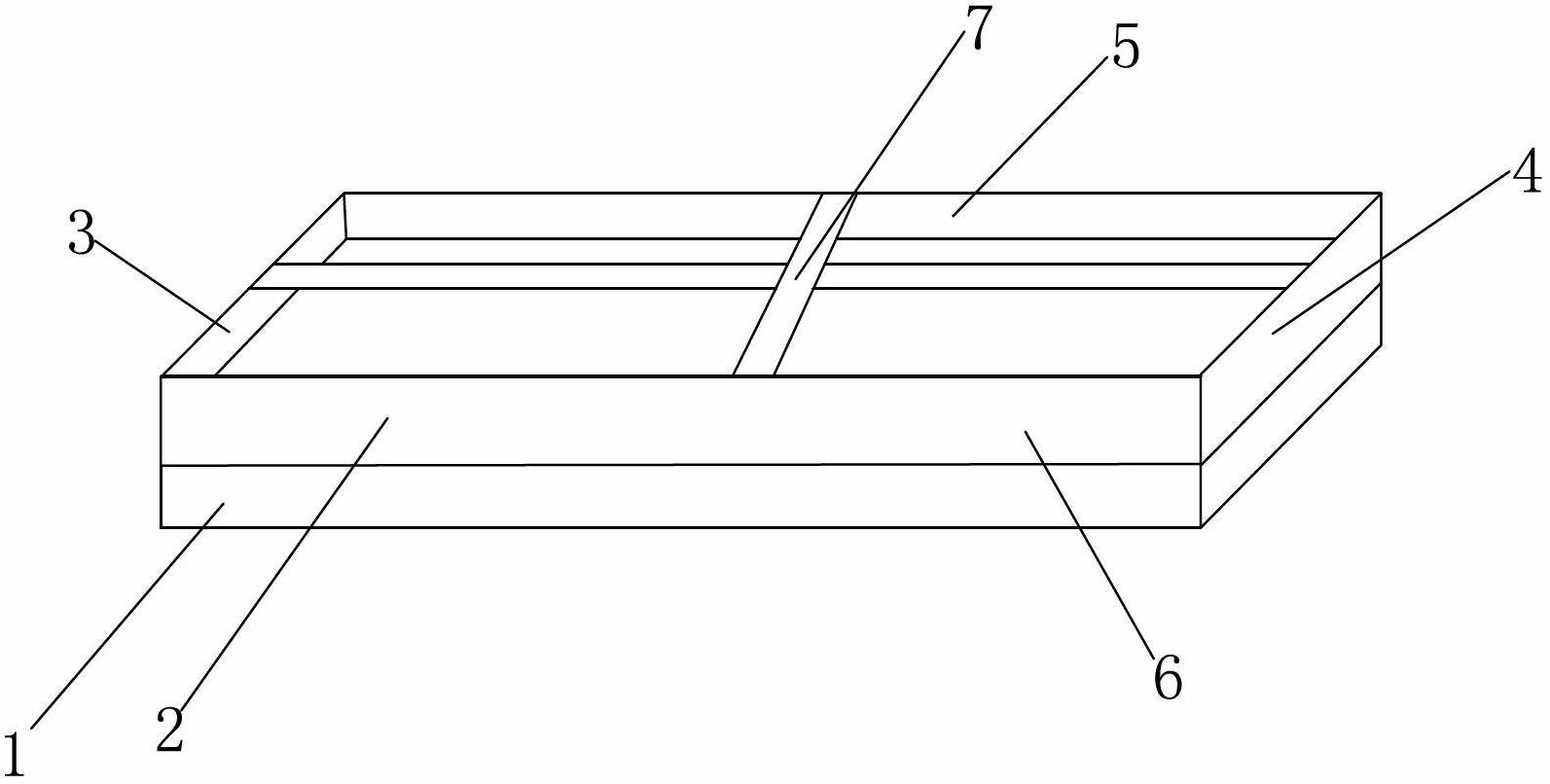

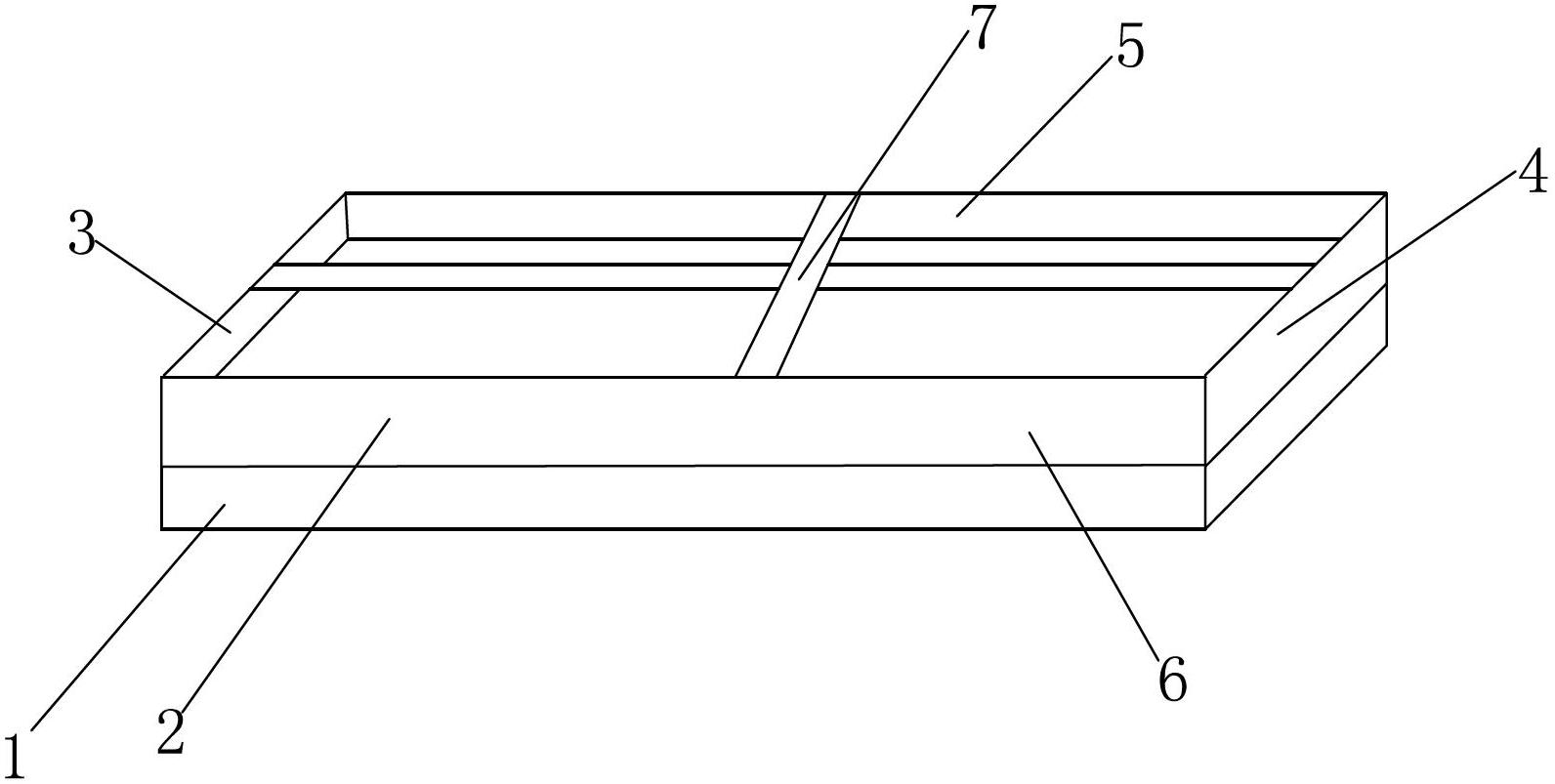

[0013] Embodiment: a kind of platen mechanism for packing machine, as figure 1 As shown, it includes a pressing plate 1 and a metal frame 2, the pressing plate 1 is a wooden board, the pressing plate 1 is located under the metal frame 2 and connected with the metal frame 1 by screws. The metal frame 2 is enclosed by left and right side plates 3, 4 and front and rear side plates 5, 6, and a cross-shaped reinforcement plate 7 is fixedly arranged in the metal frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com