Damping and buffering expansion joint and construction method thereof

An expansion joint and section steel technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of time-consuming and laborious installation, difficult replacement of rubber sealing belts, and restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

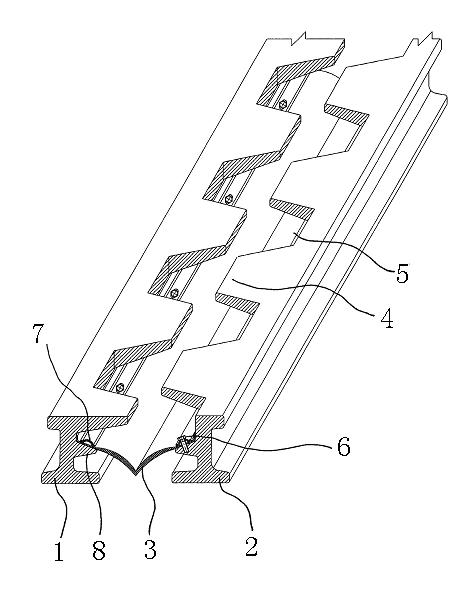

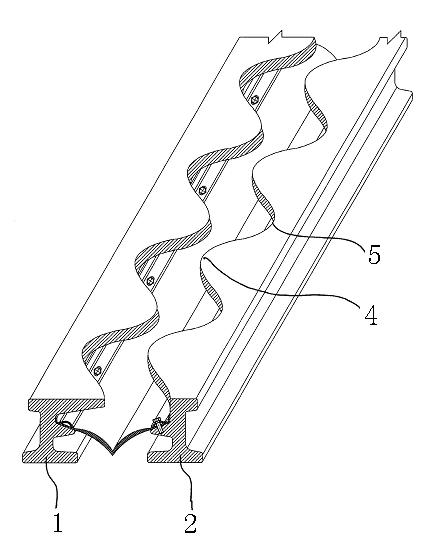

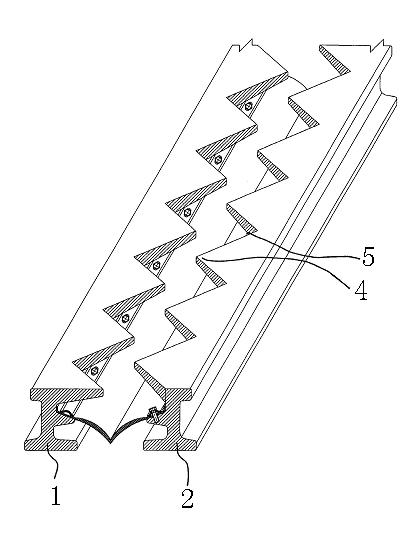

[0016] The structure of the shock-absorbing buffer expansion joint provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the shock-absorbing and buffering expansion joint of the present invention includes profiled steel side beams 1 and 2 arranged in pairs, a rubber sealing belt 3 is arranged between the profiled steel side beams 1 and 2, and the top edge of the inside of the profiled steel side beams 1 and 2 is a protruding tooth 4 , the concave and convex shape of the groove 5 is circularly set, the convex teeth 4 and the groove 5 on the inner top edge of the shaped steel side beams 1 and 2 are trapezoidal, and the rubber sealing belt 3 is fixed to the shaped steel side beams 1 and 2 through bolts 6, and the bolts 6 are set At the groove 5 on the inner side of the shaped steel side beams 1 and 2, a compression elastic strip 7 is arranged on the top of the rubber sealing strip 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com