A kind of installation tool suitable for the integral clamp spring of the porcelain cylinder coil

An integrated technology for installing tooling, applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of printed board stress, ceramic cylinder rupture, circlip solder joint disturbance, etc., to achieve stable avoidance, application The effect of low pressure and guaranteed degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

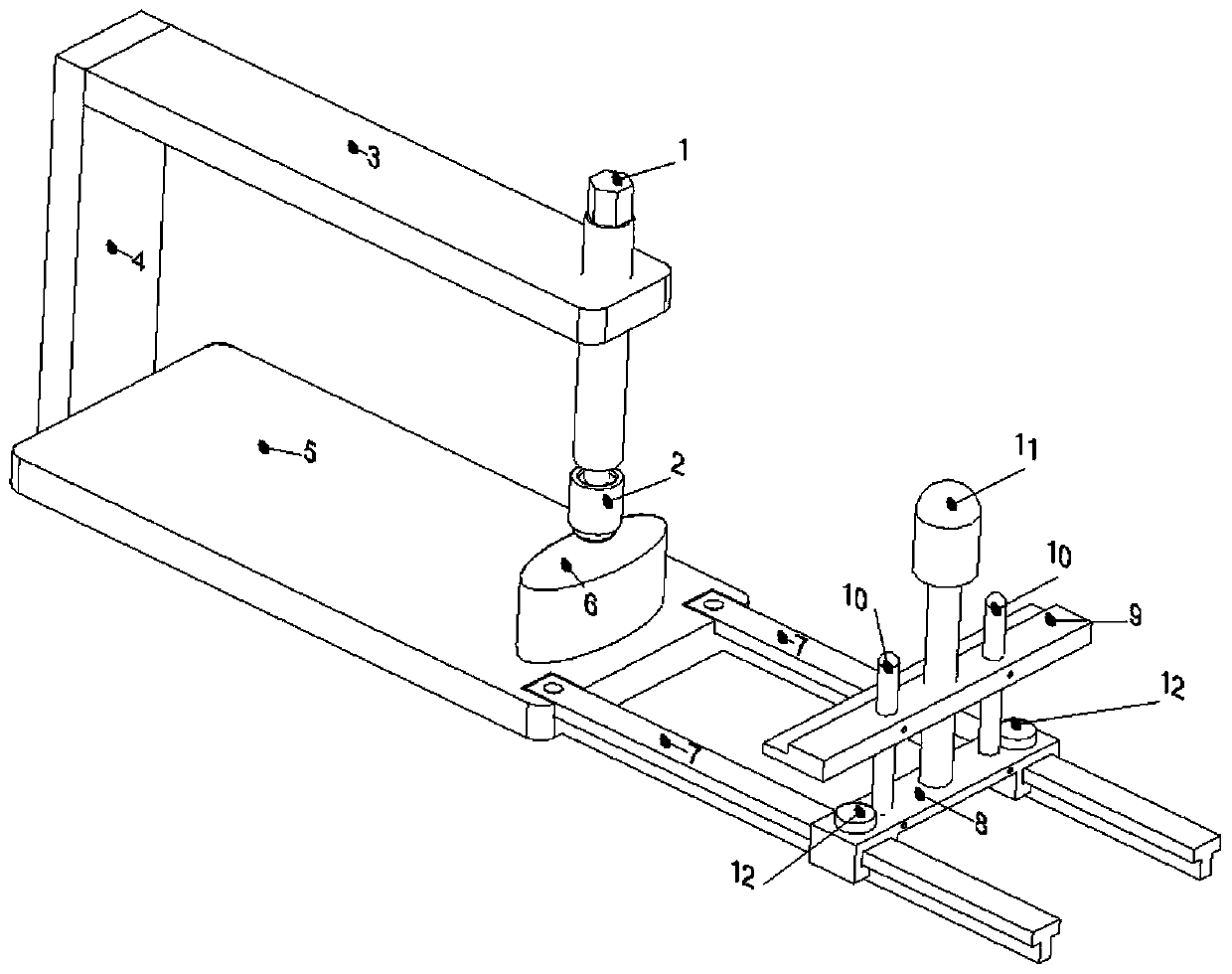

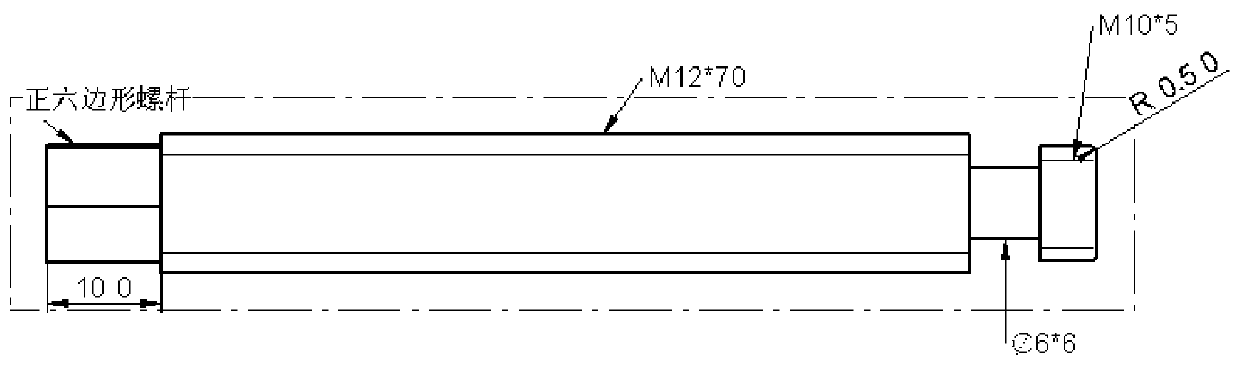

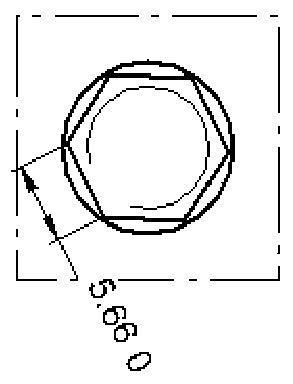

[0045] Figure 2A is the front view of the force screw 1, Figure 2B It is a side view of the force applying screw 1. As shown in the figure, the upper end of the force applying screw 1 is an external hexagonal screw with a length of 10 mm. The middle section of the force applying screw 1 is a long threaded rod with a diameter of 12 mm and a length of 70 mm. The lower end of force screw rod 1 is a small thread, with a diameter of 10mm and a length of 5mm, which is used to fix the force-applying top cap 2. The small thread is connected with a long threaded rod through a polished rod, and the polished rod has a diameter of 6mm and a length of 6mm. Figure 3A It is the front view of Shili top hat 2, Figure 3B is a side view of the force application cap 2, Figure 3CIt is the A-A sectional view of the force application top cap 2. As shown in the figure, the length of the connection section of the force application top hat 2 is 13mm, the diameter is 13mm, the length of the force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com