Arm tension spring structure of awning

An awning and arm technology, applied in the field of awning arm tension spring structure, can solve problems such as inconvenient disassembly and assembly, and achieve the effects of convenient and simple disassembly and assembly, convenient manufacturing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

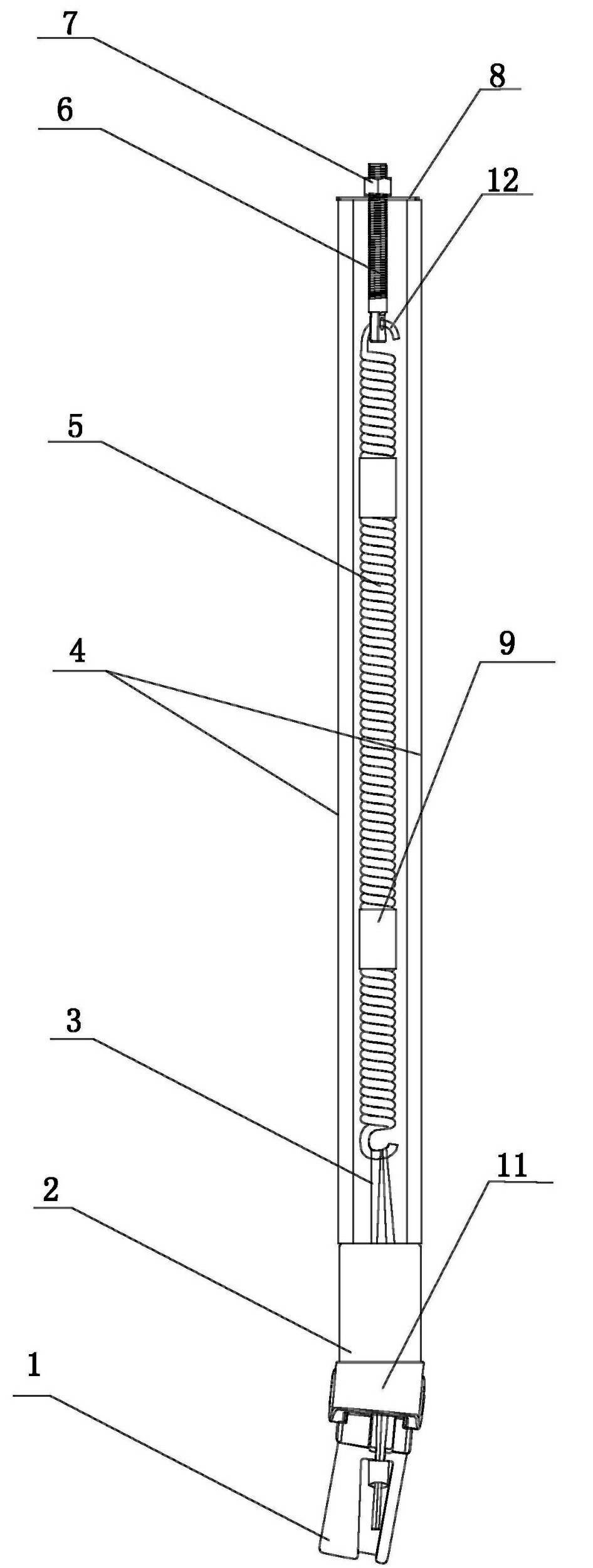

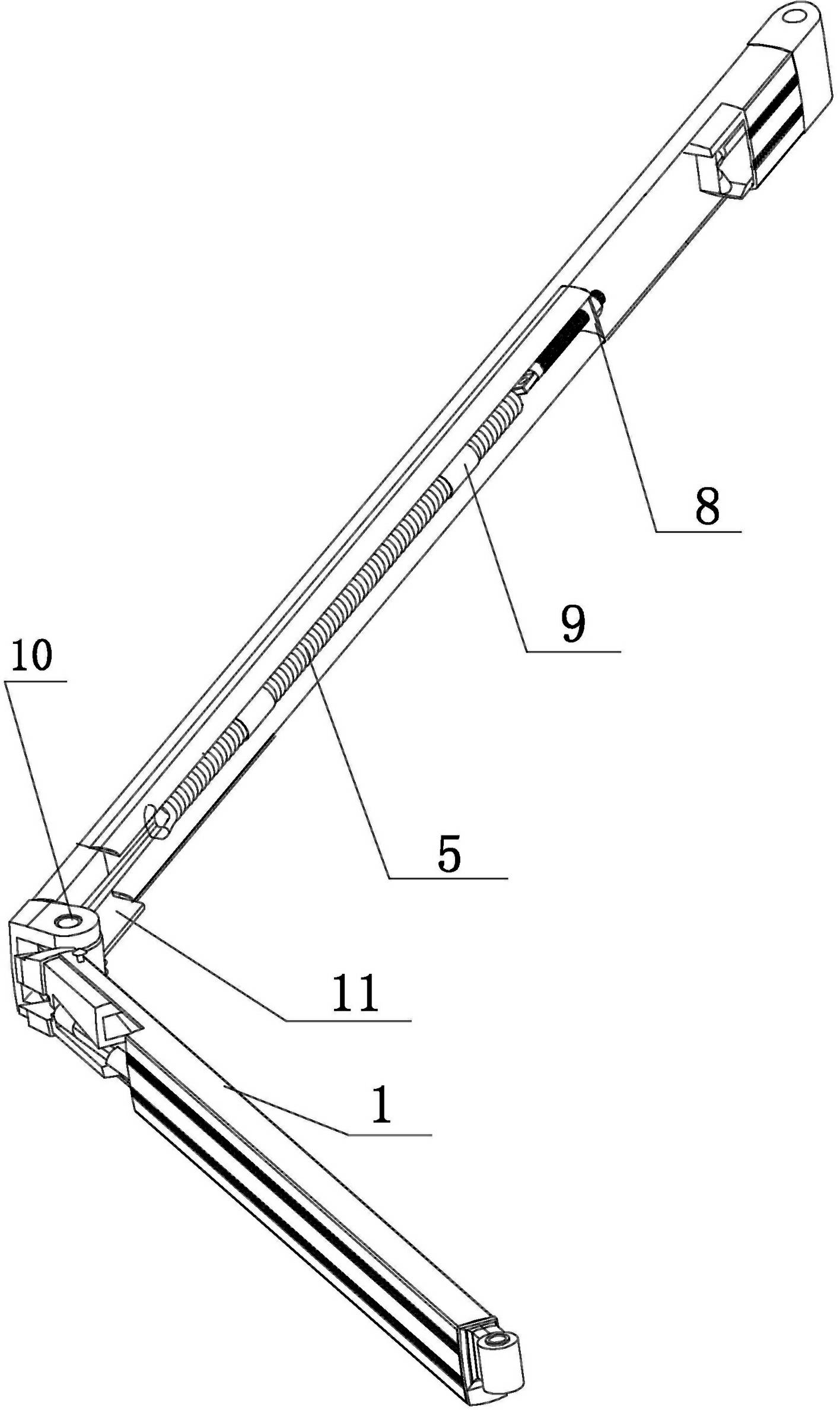

[0019] Example 1: Such as figure 1 As shown, a tension spring structure for an awning arm includes a tension spring 5. One end of the tension spring is connected to an adjusting screw 6, and the other end of the tension spring is connected to a wire rope 3. The adjustment screw is provided with a hexagon nut 7, and the wire rope is fixed on the forearm On the hinge base 2, one end of the fixed sleeve 4 is fixedly connected to the forearm hinge base, the other end is fixedly connected to the gasket 8, and the forearm hinge base is connected to the forearm hinge 1.

[0020] The fixed sleeve is a support sleeve rod, two support sleeve rods are provided, and the tension spring, the adjusting screw and the steel wire rope are arranged between the two support sleeve rods.

[0021] The tension spring is provided with three sections, and each two sections of the tension spring are fixedly connected by a connecting sleeve 9. The section connecting the tension spring and the adjusting screw ...

Embodiment 2

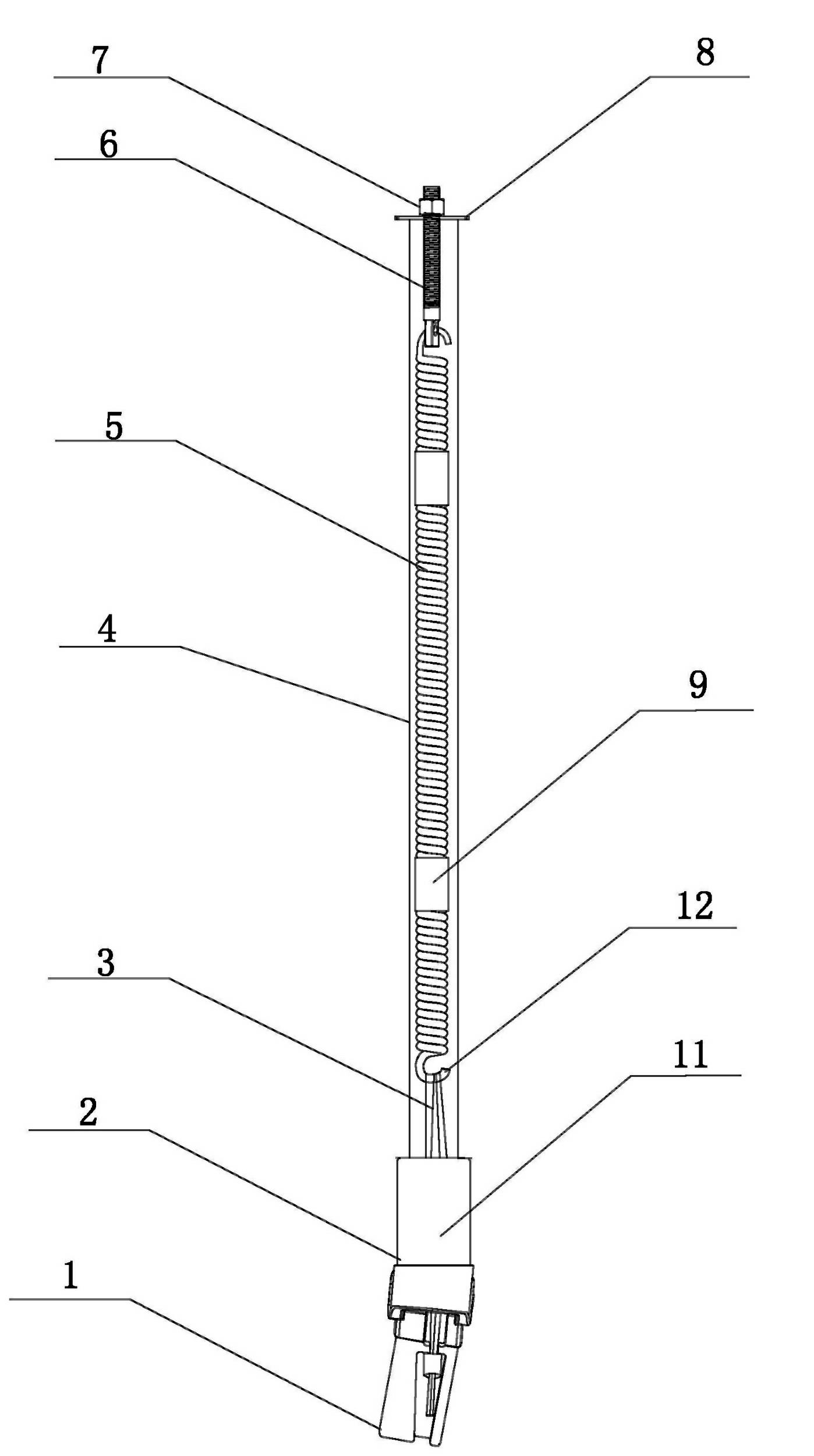

[0024] Example 2: Such as figure 2 As shown, a tension spring structure of an awning arm, the fixed sleeve is an iron sleeve, and the tension spring, the adjusting screw and the steel wire rope are arranged in the iron sleeve. The other structure is the same as the first embodiment.

[0025] The invention adopts the connection mode of the fixed sleeve, that is, the fixed connection mode of the iron sleeve or the supporting sleeve rod, which changes the fixed connection of the traditional tension spring, makes disassembly and assembly more convenient and simple, and also makes the force of the tension spring adjustable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com