Diesel engine cylinder head

A cylinder head and diesel engine technology, applied in the direction of cylinder head, cylinder, mechanical equipment, etc., can solve the problems of harsh working conditions of the engine cylinder head, failure to meet the cooling requirements, increase the difficulty of manufacturing, etc., to optimize the direction of water flow, improve economical, The effect of reducing the probability of scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

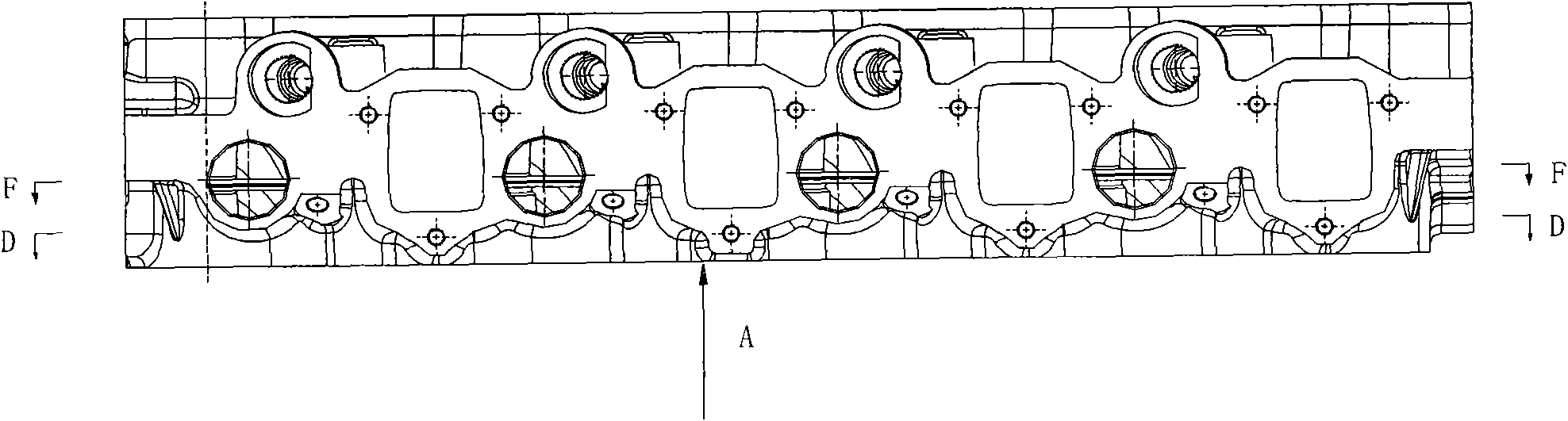

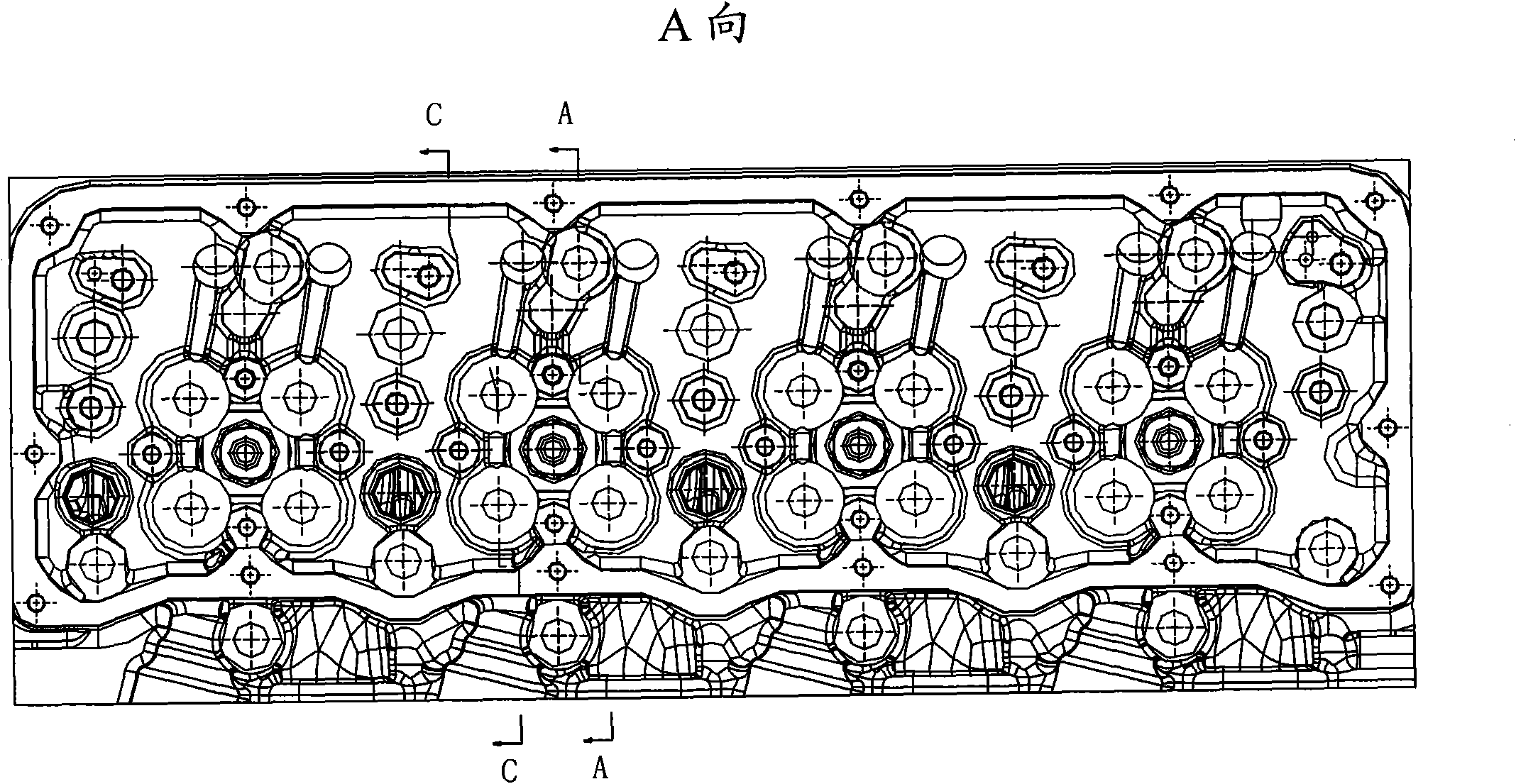

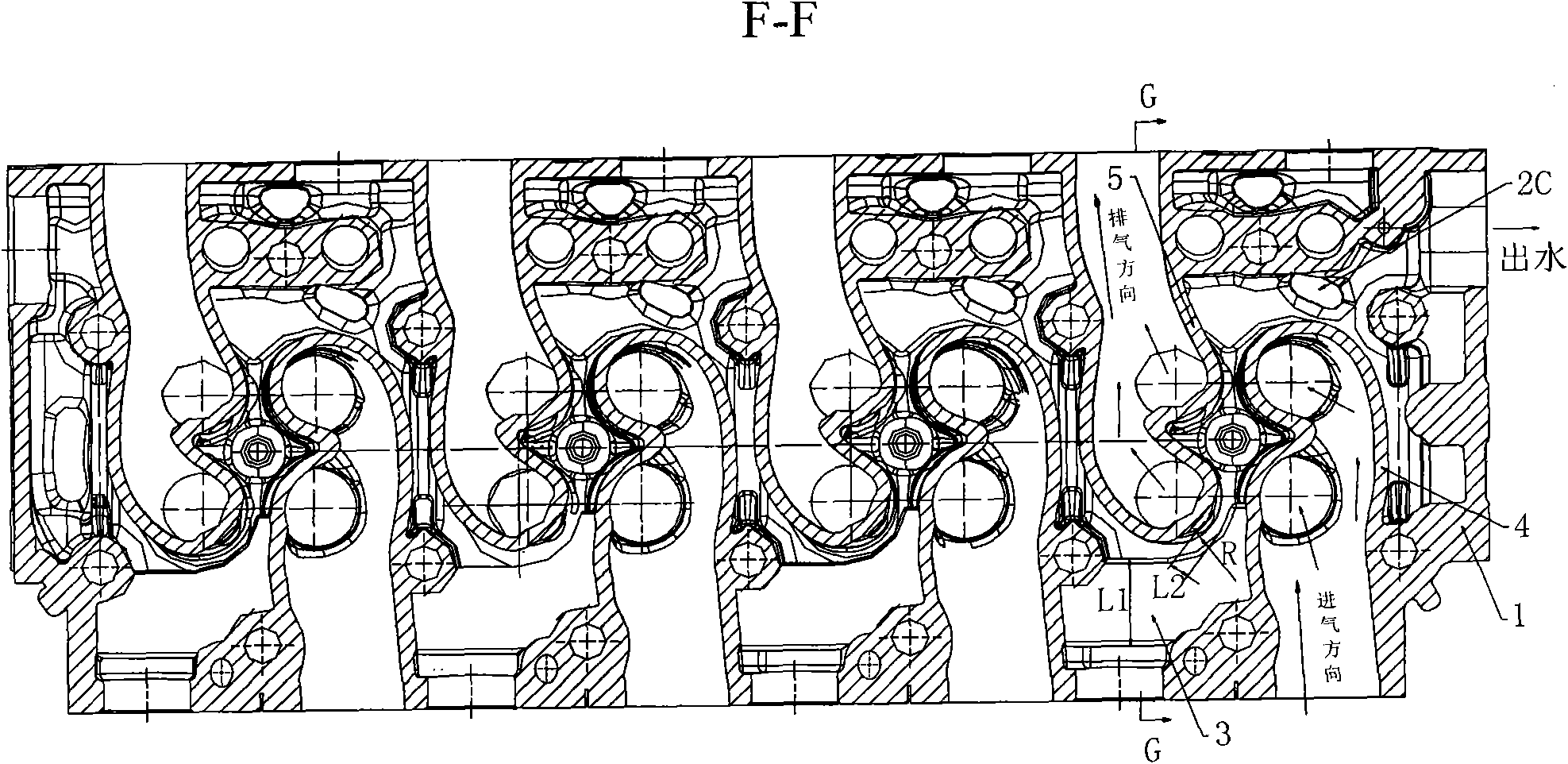

[0026] Such as figure 1 Shown is the front view of the cylinder head of the four-valve diesel engine of the present invention; figure 2 for figure 1 A view from direction A. Such as Figure 3-6 As shown, the cylinder head body 1 is provided with an upper water hole 2 (including an upper water hole 2a, an upper water hole 2b, an upper water hole 2c, and an upper water hole 2d), an air inlet wall 4, an exhaust wall 5, The upper water hole 2 is provided with a water baffle 3 above the air intake side (such as image 3 , 4 As shown), there is a deflector 6 between the bottom of the cylinder head body 1 and the water baffle 3, the water baffle 3 is connected with the two inlet walls, and the thickness of the water baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com