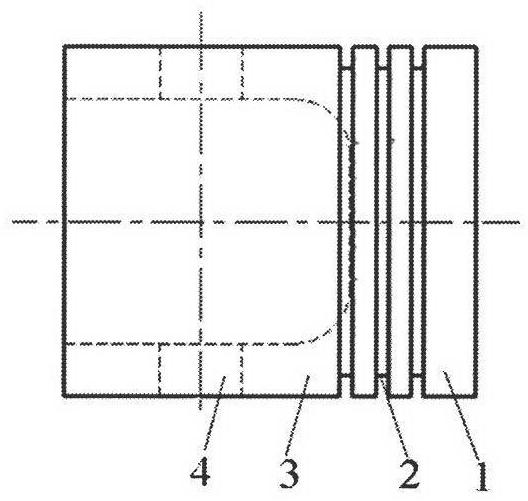

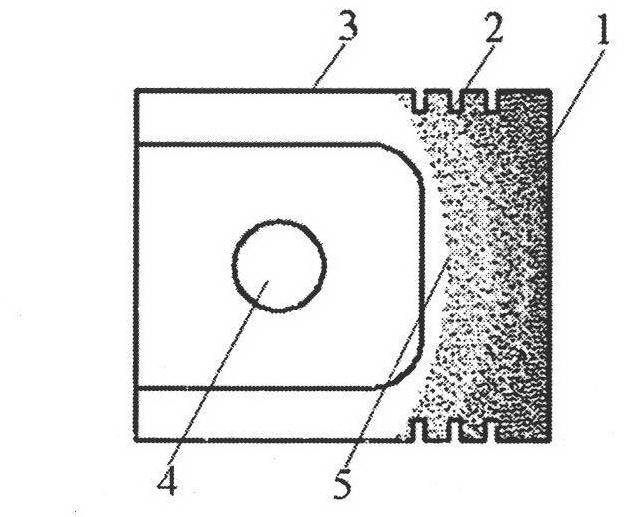

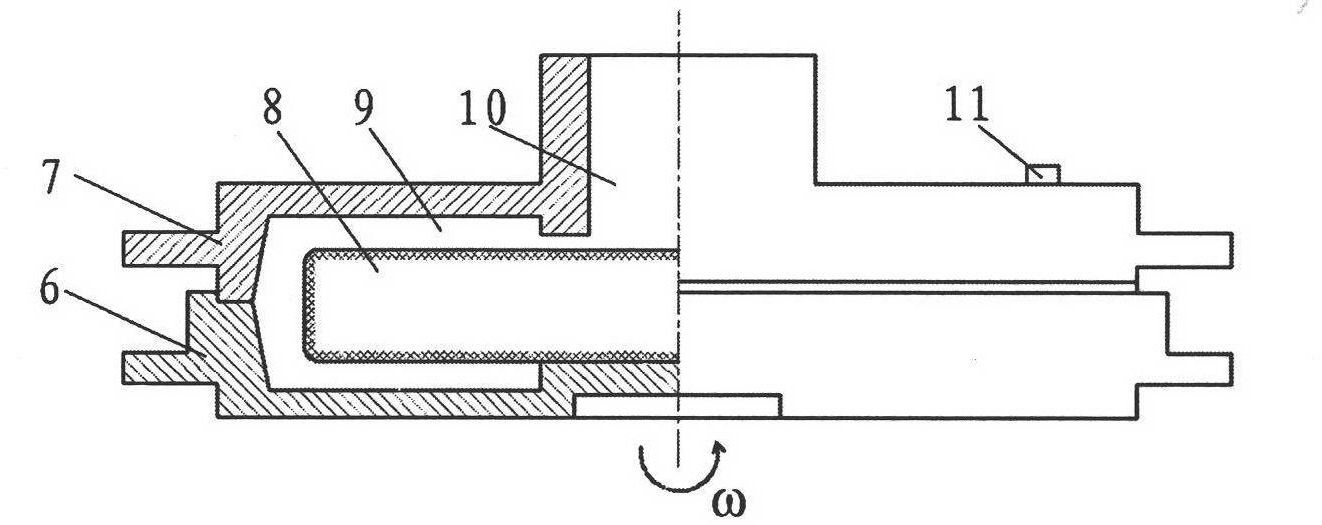

Al-Si-Ti composite local reinforcement piston and preparation method thereof

A technology of al-si-ti and composite materials, applied in the field of locally reinforced pistons of Al-Si-Ti composite materials and its preparation, can solve the problems of composite materials without primary reinforcement phase, and achieve good comprehensive mechanical properties, Excellent mechanical properties, smooth and continuous transition of structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The alloy composition is Al-15Si-5Ti, the hardness of the reinforced area is higher than HRB60, and it has excellent wear resistance.

Embodiment 2

[0029] The alloy composition is Al-15Si-10Ti, and the hardness and wear resistance of the reinforced area in this embodiment are better than those in the first embodiment.

Embodiment 3

[0031] The alloy composition is Al-15Si-15Ti, and the hardness and wear resistance of the reinforced area of this embodiment are better than those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com