Abnormal-shaped seal ring, lamp casing and lamp

A special-shaped seal and lamp technology, applied in the field of lighting, can solve the problems of difficult lamps and O-shaped sealing rings, etc., and achieve the effects of labor-saving assembly, reduced frictional resistance, and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

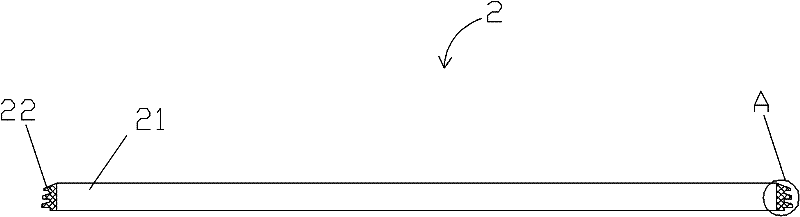

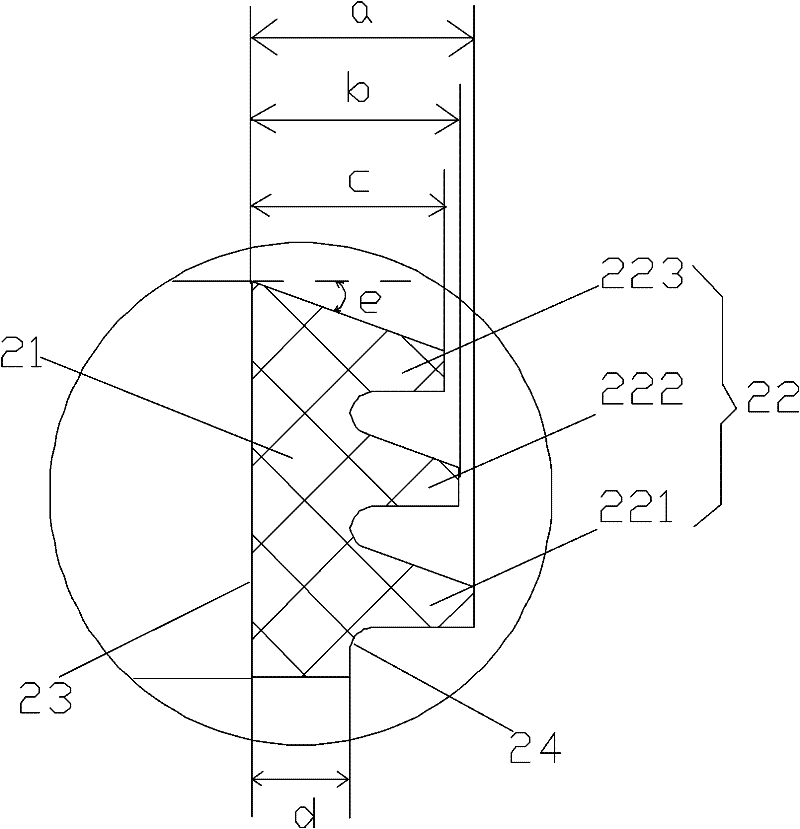

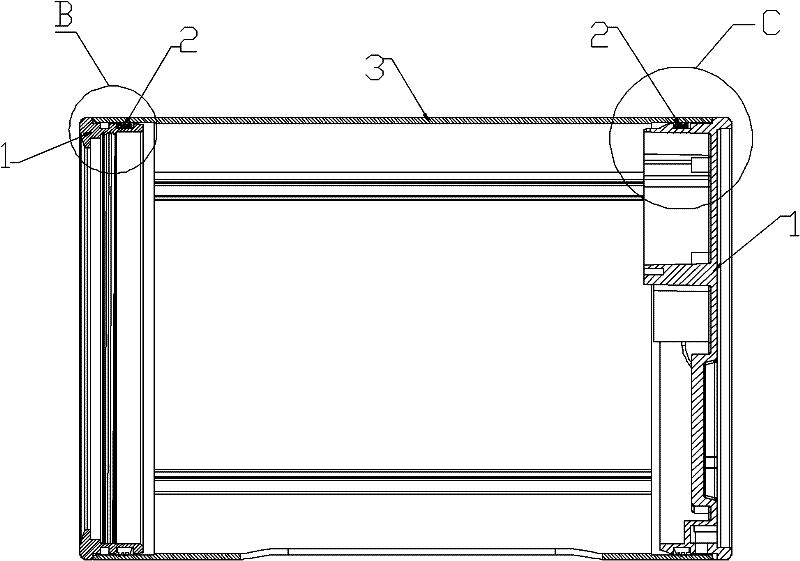

[0026] The cross-sectional structure of the special-shaped sealing ring in the preferred embodiment of the present invention is as follows: figure 1 shown, see also figure 2 , image 3 , Figure 4 and Figure 5 , The special-shaped sealing ring 2 is used to be placed in the sealing groove 11 of any end cover 1 on the lamp, and is pressed by the inner surface of the lamp housing 3 to realize the sealing of the lamp. The special-shaped sealing ring 2 includes an annular base 21 , and the annular base 21 includes an inner surface 23 for press fit with the bottom surface of the sealing groove 11 , and an outer surface 24 for press fit with the inner surface of the housing 3 . Wherein, a plurality of protrusions 22 are arranged on the outer surface 23 of the annular base 21, and the distance between the top end of each protrusion 22 and the inner surface of the annular base 21 gradually increases sequentially, and the plurality of protrusions 22 all move toward the top end to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com