Relay and assembly method thereof

A relay and mounting frame technology, applied in the field of relays and their assembly, can solve the problems of small structure of lead pieces and lead pins, small welding space for welding parts, and easy occurrence of false welding during welding, so as to achieve convenient assembly, solve the problem of false welding, Stable plug-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0033] Please refer to Figure 1-Figure 6 , the relay of the present invention, it comprises:

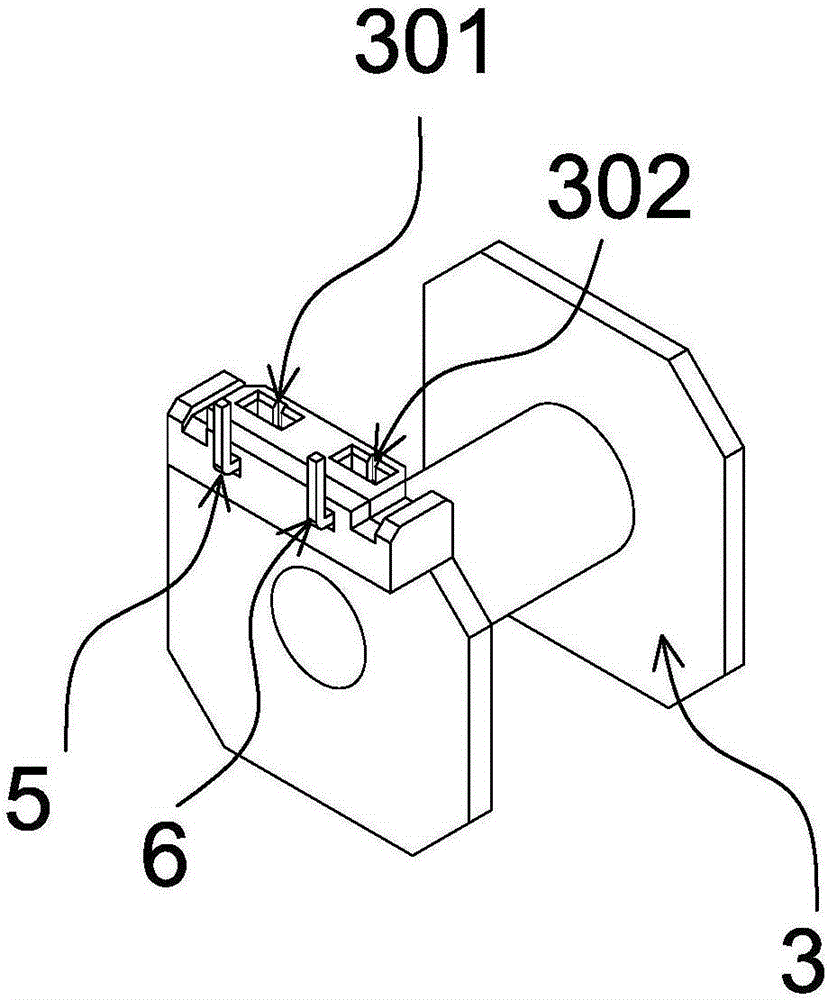

[0034] Coil frame 3;

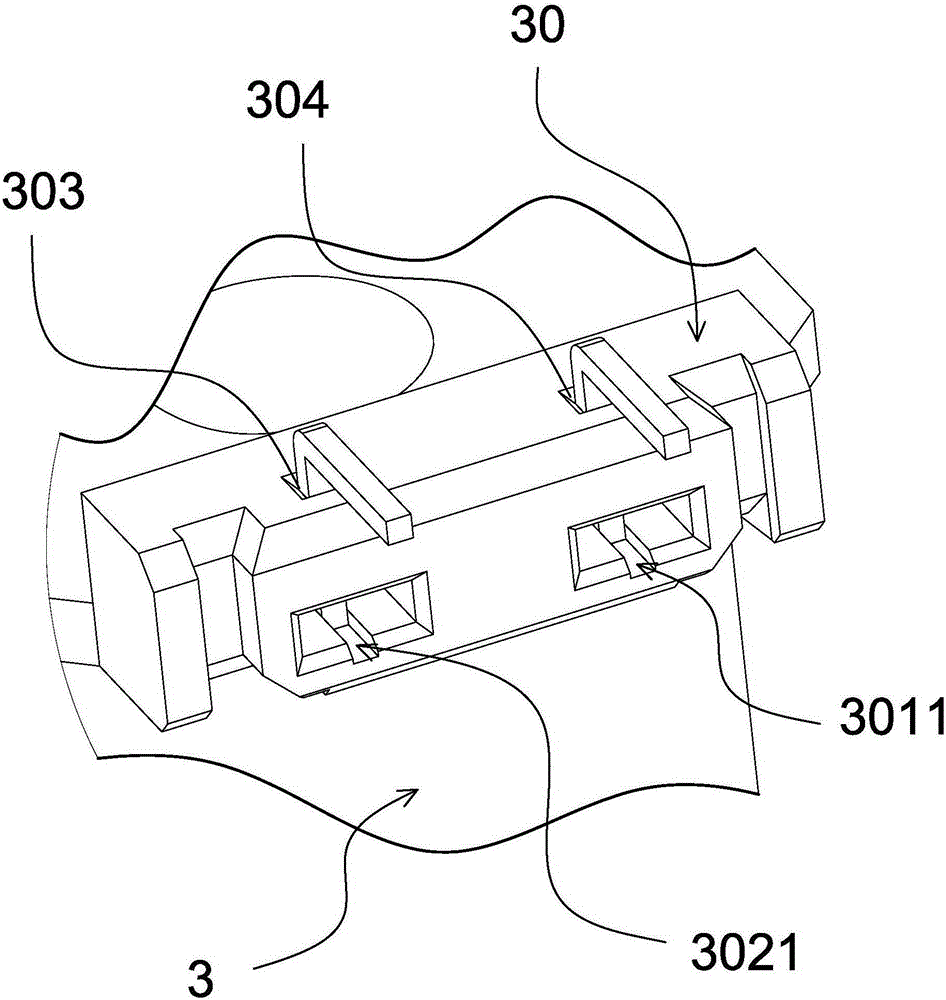

[0035] The mounting frame 30 is arranged on the coil frame 3; the outer surface of the mounting frame is formed with lead wire sockets (303, 304), and the top surface is formed with lead sheet sockets (301, 302), and the lead wire sockets and corresponding lead sheet sockets connected;

[0036] Lead wire needles (5, 6), partly inserted in the lead wire needle sockets (303, 304);

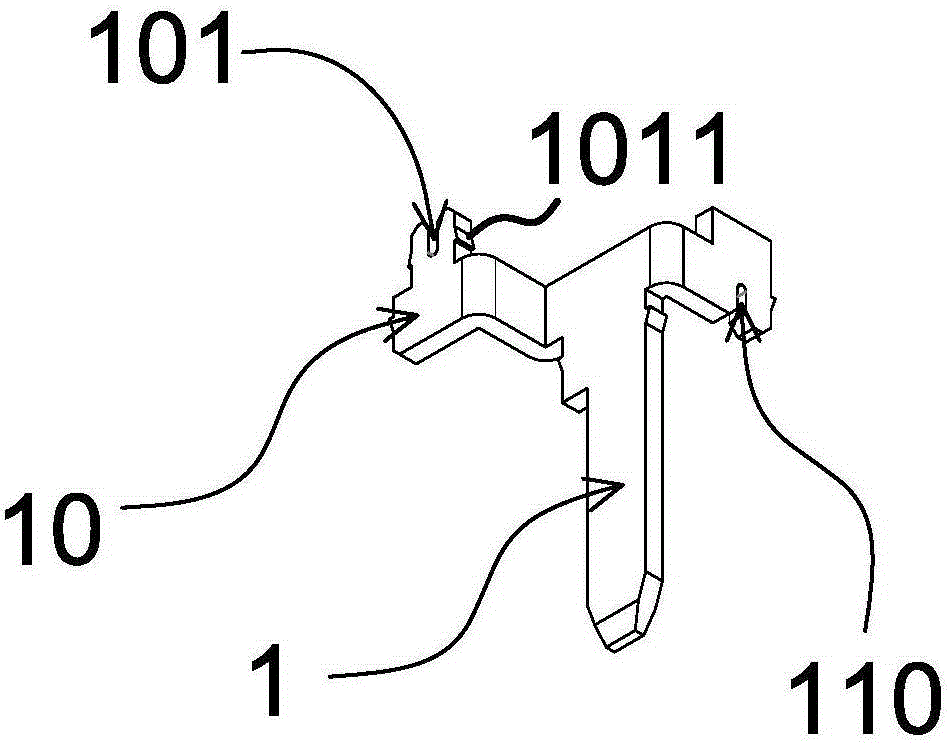

[0037] The lead sheet (1, 2) has a plug-in part 10, and the middle part of the plug-in part forms a first snap-in slot (101, 201); the plug-in part is inserted in the socket of the lead sheet, and passes through the first snap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com