Stationary cam cylinder

A technology for fixing cams and cam barrels, applied in installation, optics, instruments, etc., can solve problems such as abnormal sound and jamming of the lens, and achieve the effect that it is not easy to shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to illustrate the present invention more clearly, preferred embodiments are given and described in detail with accompanying drawings as follows.

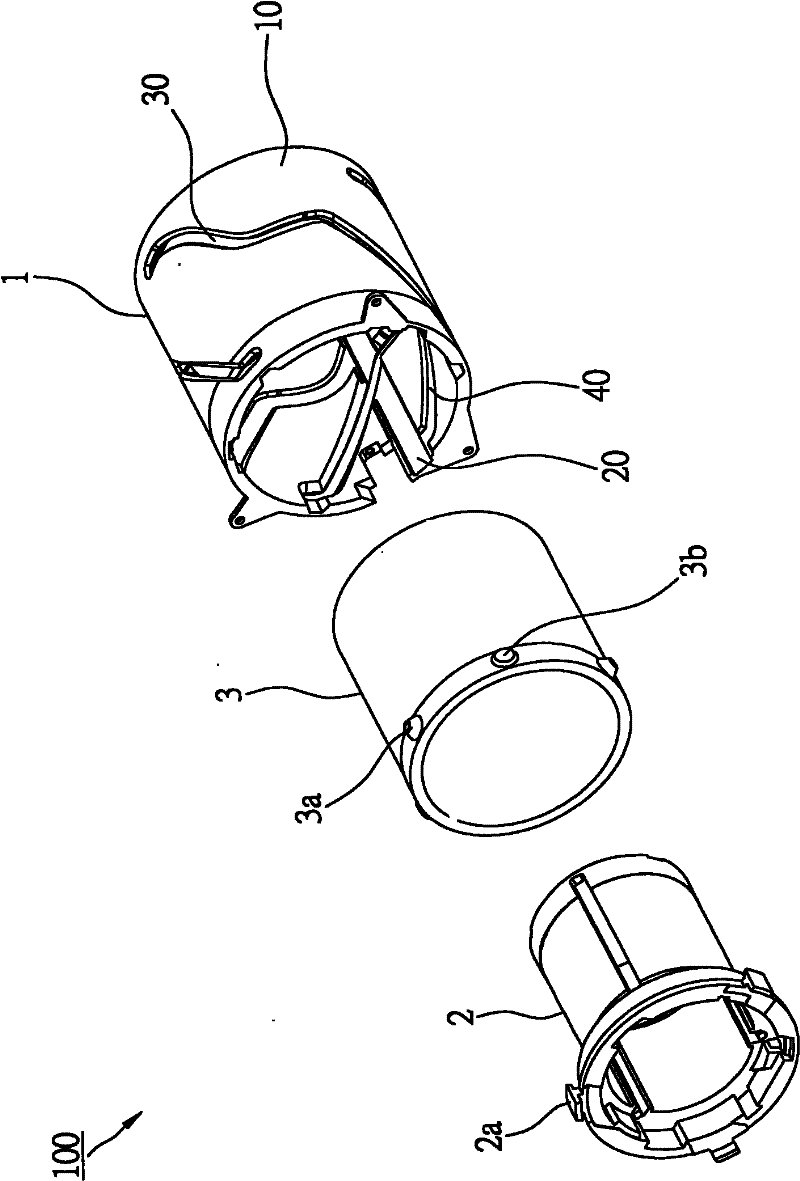

[0016] see figure 2 , the lens module 100 of the preferred embodiment of the present invention includes a fixed cam barrel 1 , a lens barrel 2 and a rotating cam barrel 3 . in:

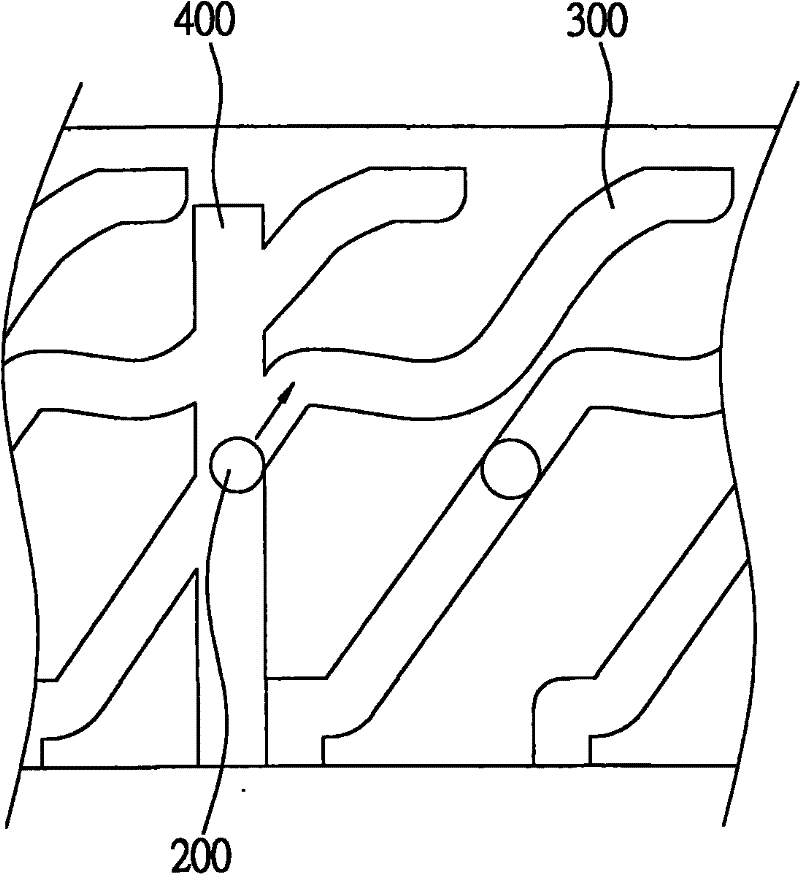

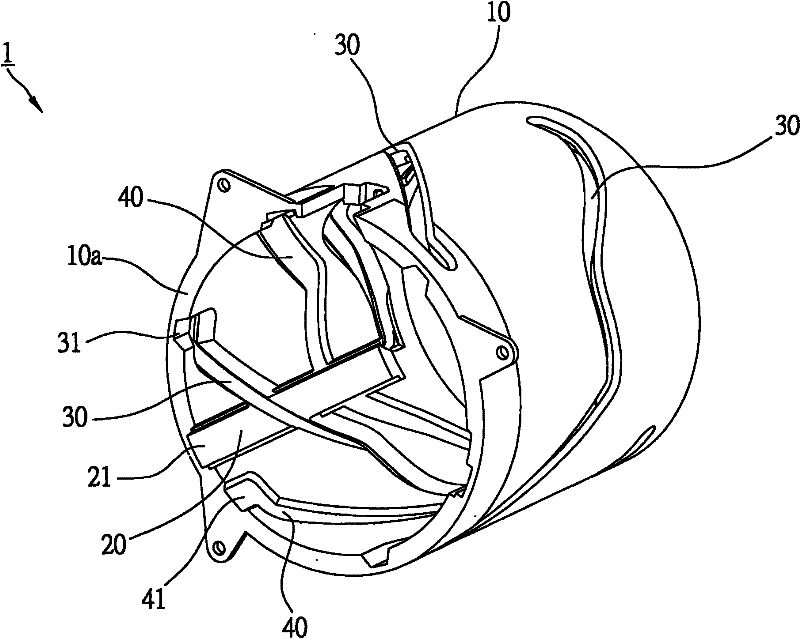

[0017] continued Figure 3 to Figure 5 , the fixed cam cylinder 1 includes a cylinder body 10 , and three guide grooves 20 , three first actuation grooves 30 and three second actuation grooves 40 arranged on the inner wall of the cylinder body 10 . The cylinder body 10 has a first end 10a, and each of the guiding slots 20 has a first opening 21 formed at the first end 10a. In addition, in this embodiment, each of the guide grooves 20 goes straight into the groove, but it is not limited thereto, and the guide grooves 20 can also be other types of grooves in terms of design.

[0018] These first actuation grooves 30 run through the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com