Flow control switching valve for automobile emergency steering system

An emergency steering and flow control technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve problems such as vehicle steering failure, non-compliance, and easy occurrence of safety accidents, so as to improve system life and improve safety. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Firstly, the structure of each component of the present invention will be described separately.

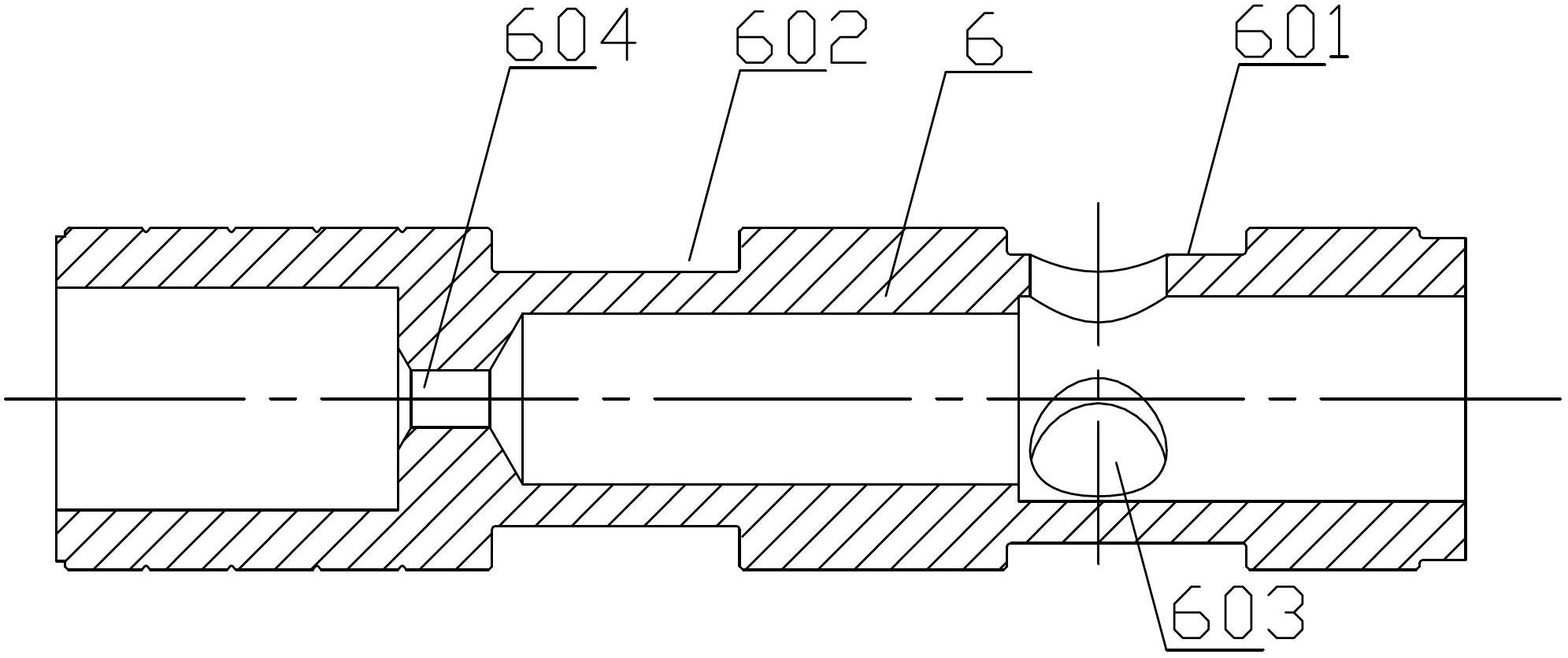

[0026] Such as figure 1 As shown, the outer surface of the main valve core 6 of the present invention is perpendicular to its length direction and is successively provided with spaced first grooves 601 and second grooves 602, the first groove 601 is closer to the oil inlet of the main steering pump, and the second There are three small holes 603 leading to the inside of the main valve core 6 on a groove 601, and a small-diameter oil hole 604 is arranged inside the main valve core 6, and the inside of the main valve core 6 appears to be connected by the small-diameter oil hole 604. There are two chambers. In this embodiment, the one directly connected to the oil inlet of the main steering pump is the right chamber, and the other is the left chamber. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com