Tensioning elongation value measuring device for prestressed tensioning construction

A measuring device and prestressing technology, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of jack fall damage, measurement danger, jack cylinder elongation exceeding the standard, etc., so as to avoid tension jack fall and ensure Personal safety and the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

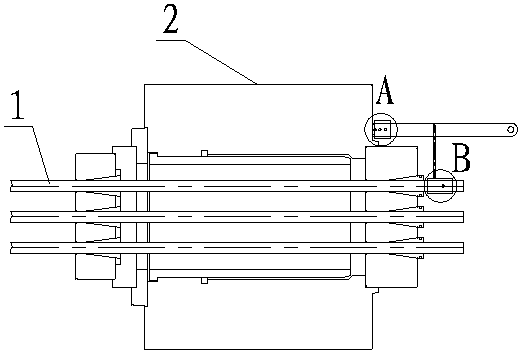

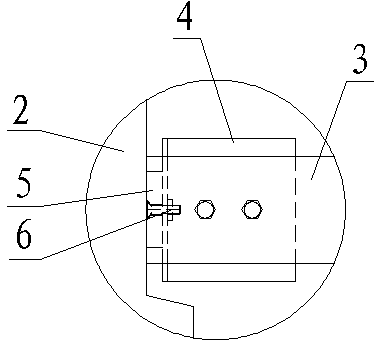

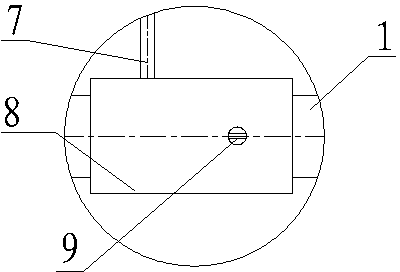

[0019] as attached Figure 1-7 As shown, a tension elongation measurement device for prestressed tension construction includes a scale device and a pointer device. The scale device includes a scale 3 and a base 4 fixedly connected to the initial scale end of the scale 3 . In this embodiment, the scale 3 adopts a straight steel ruler, and the base 4 is an angle steel structure. The initial scale end of the scale 3 is fixedly connected to the outside of one of the flanks of the base 4. The scale 3 can be connected by bolts or bonding or Other connection methods are connected with the base 4. The base 4 of the scale device is installed on the rear end cover of the tension jack 2 and ensures that the scale 3 is parallel to the axis of the tension jack 2, that is, ensures that the scale is perpendicular to the rear end cover of the tension jack. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com