Buoy switch

A floating body and switch technology, applied in the direction of robot floating motion actuation, etc., can solve the problems of equipment damage, dry burning, liquid level lower than electric heating/electrolytic components, etc., and achieve the effect of avoiding dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

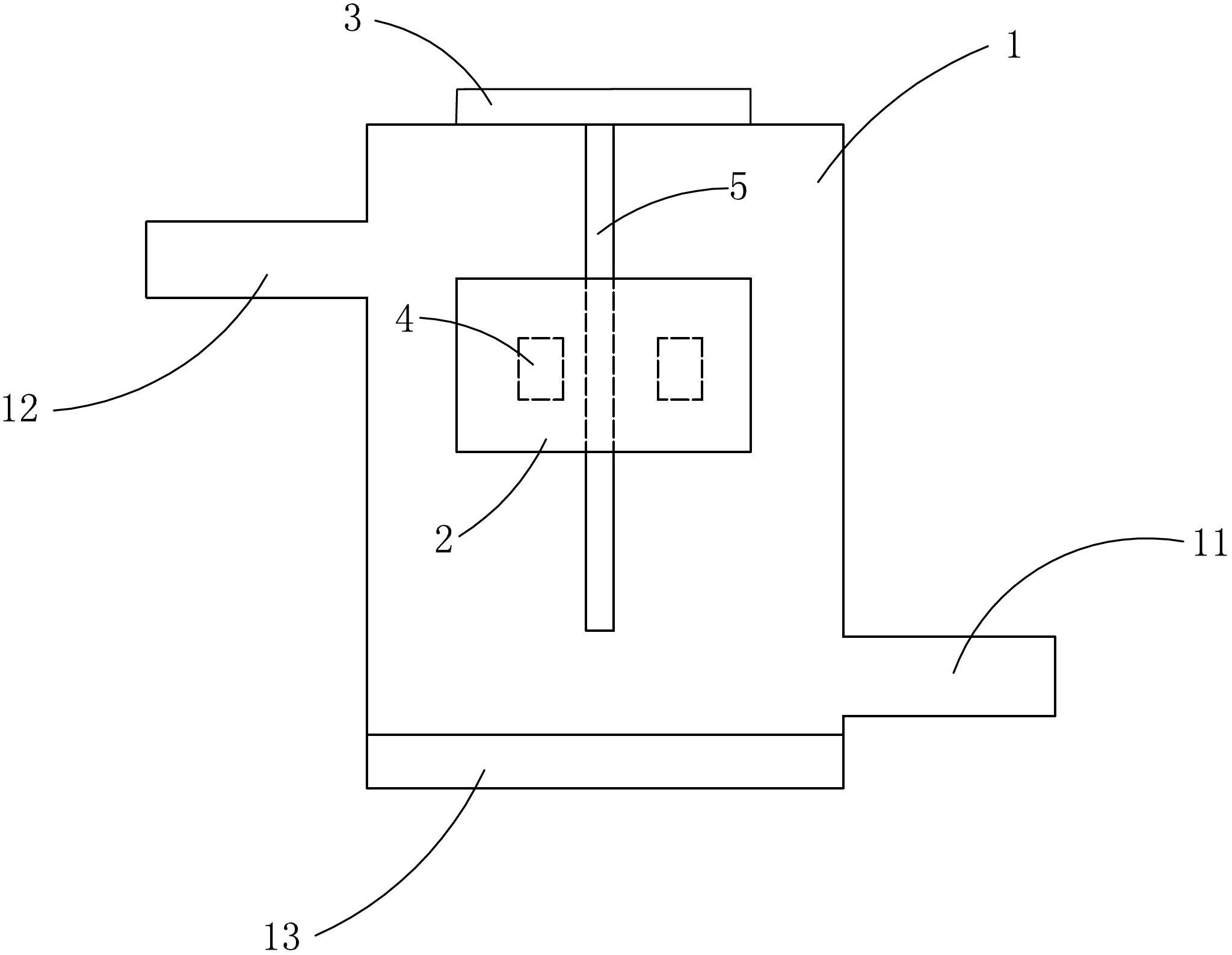

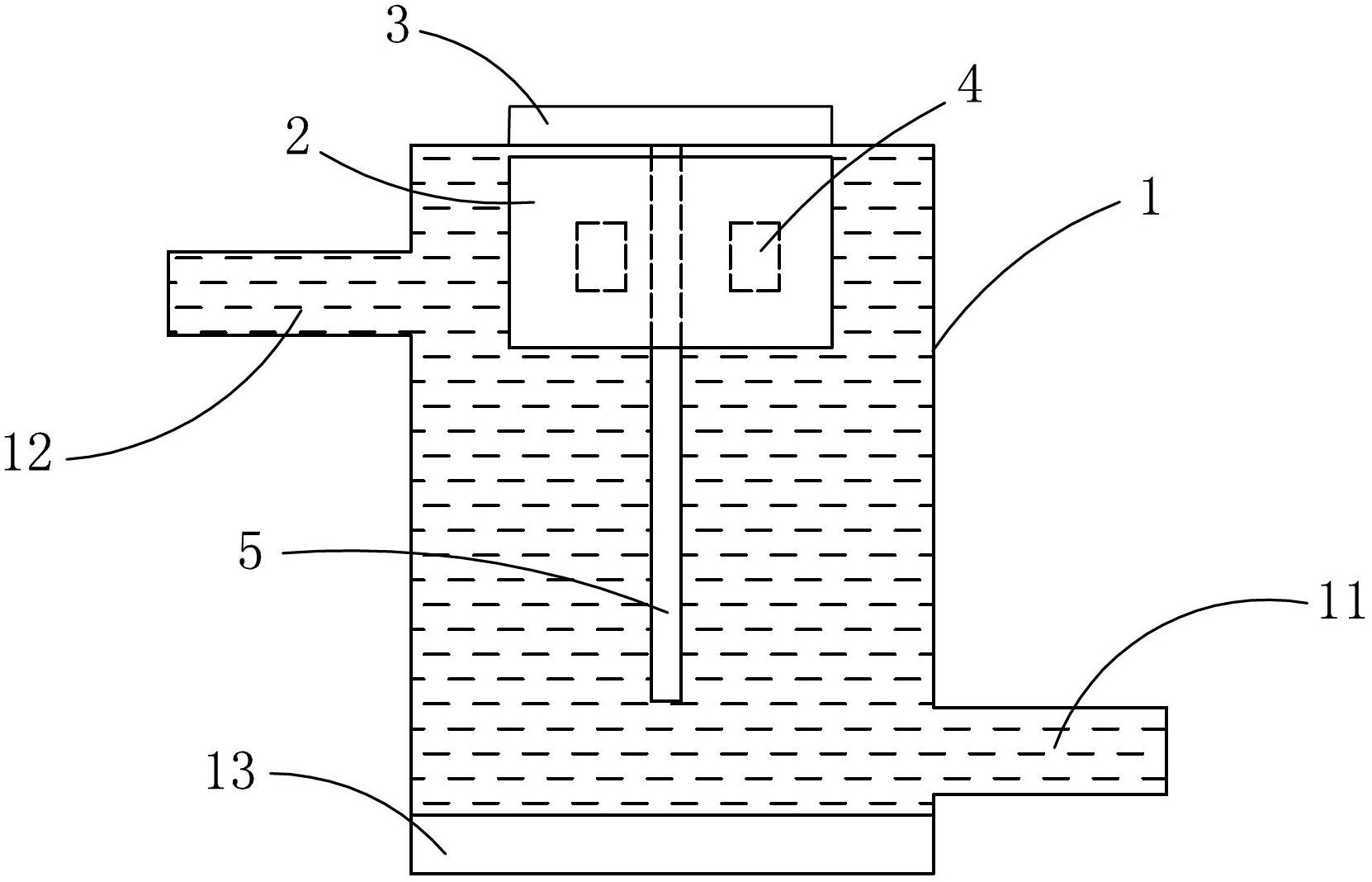

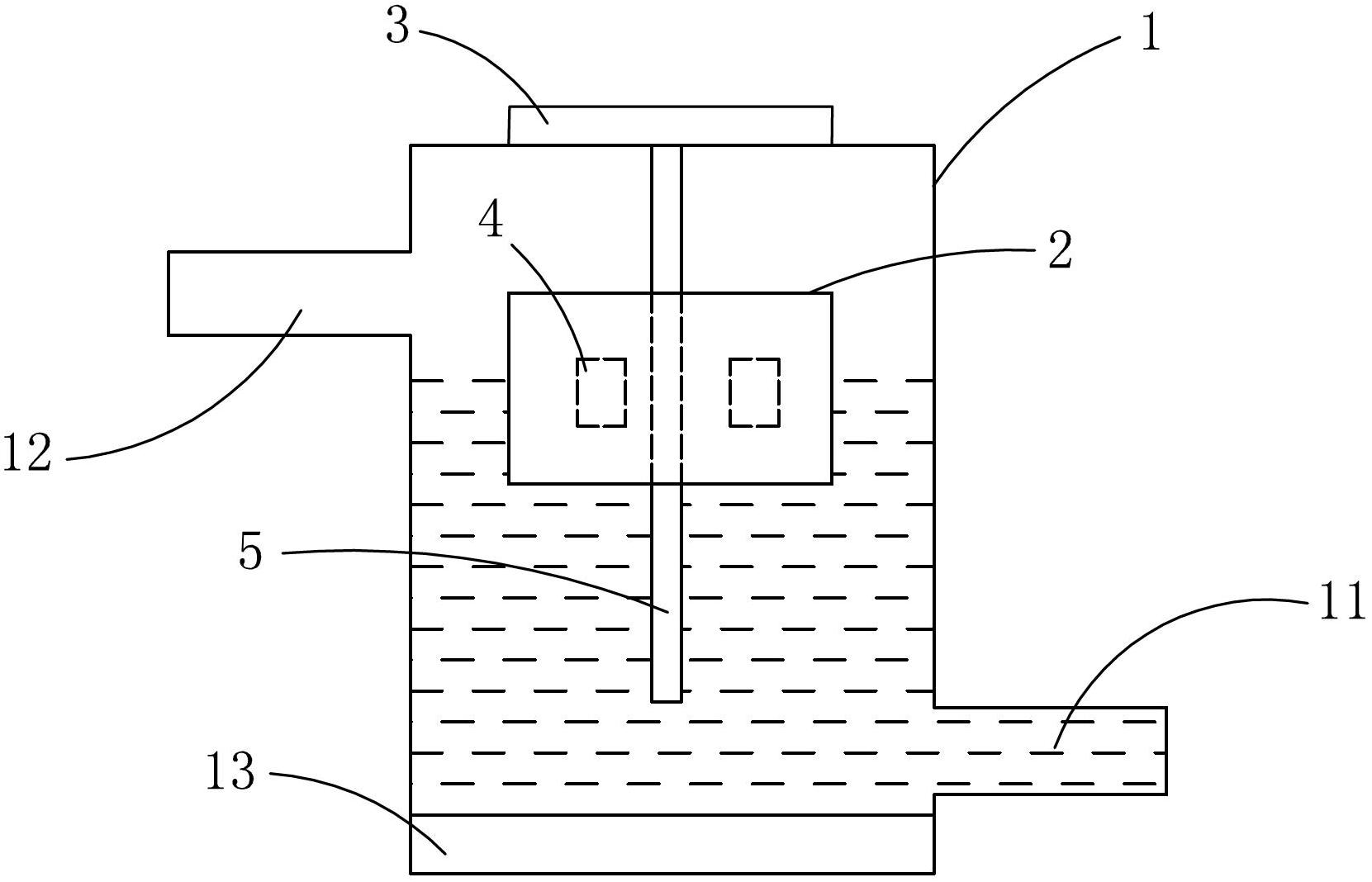

[0014] figure 1 An embodiment of a floating body switch provided by the present invention, its main body is an airtight container 1, the airtight container 1 is provided with a water inlet 11 and a water outlet 12, the water inlet 11 is connected to a water source, and the water outlet 12 is connected to an electric water heater, an electrolysis device and other equipment , the airtight container 1 is vertically provided with a guide post 5, and a floating body 2 is movable on the guide post 5. The floating body 2 is made of a material with a lower density so that it can float above the liquid in the airtight container 1, and the floating body 2 follows the liquid. The surface lift moves up and down along the guide post 5. A reed switch 3 is arranged on the top of the airtight container 1, and a magnet 4 is arranged in the floating body 2. The reed switch 3 and the magnet 4 form a reed relay, which can be used to control power switches of electric water heaters, electrolysis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com