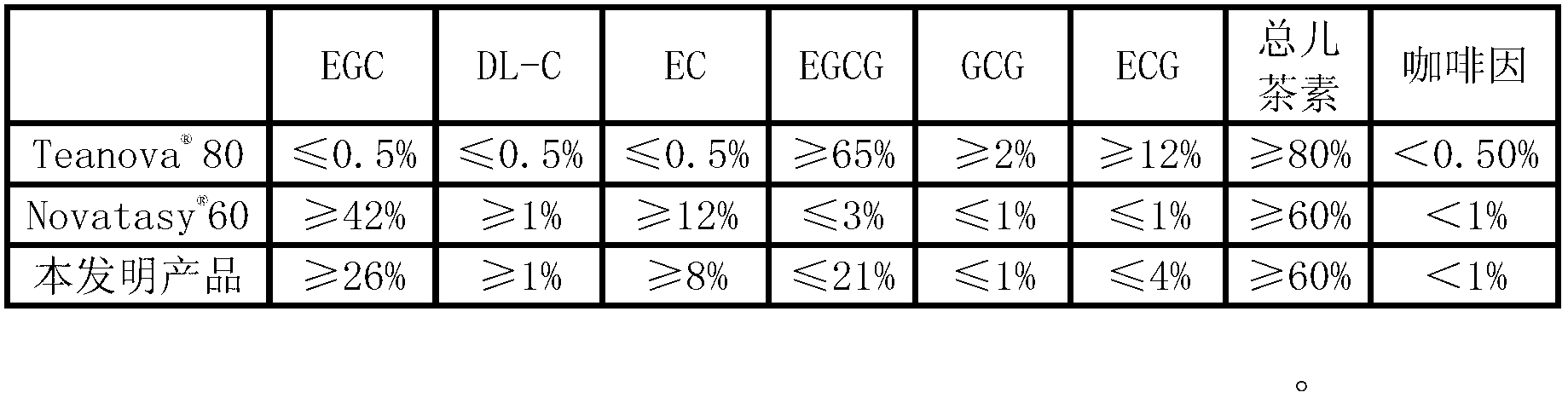

Low-caffeine bitterless high-content catechin product and preparation method thereof

A low-caffeine and catechin technology, applied in the food field, can solve the problems of unreachable catechins, and achieve the effects of prolonging the shelf life, improving incompatibility, and inhibiting bacterial growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

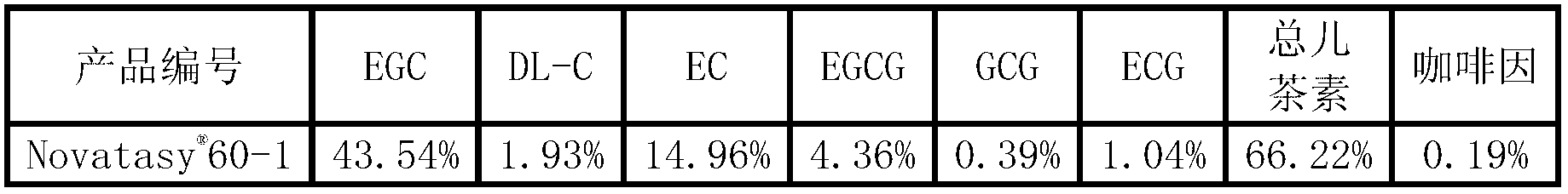

Embodiment 1

[0029] 1) Preparation 60

[0030] Put 500kg of tea leaves in accordance with GBT 14456.1-2008 into the equipment, and at 35°C, in a continuous countercurrent extractor, with tea: water ratio of 1:30W / W, feed at a rate of 120kg per hour until 1500kg of water is fed . Collect all the tea soup, filter it through stainless steel wire mesh and fine filter (WTL-cartridge filter), cool the filtered tea soup to 40°C and transfer it to the reverse osmosis concentration equipment, start the equipment, adjust the pressure at ≤11MP, and maintain the temperature Run at 40°C to concentrate the tea soup to 3Brix; adjust the pH of the tea soup to 4, add 1.3kg of tannase (2.5×10 4 U), and then start the reverse osmosis concentration equipment, adjust the pressure at 7MP, and keep the temperature at 40°C for 12 hours to concentrate the tea soup to 10Brix. The concentrated enzymolysis tea soup is at 40°C, using 5000kg of n-butanol in a countercurrent extraction equipment with 30 plates. Con...

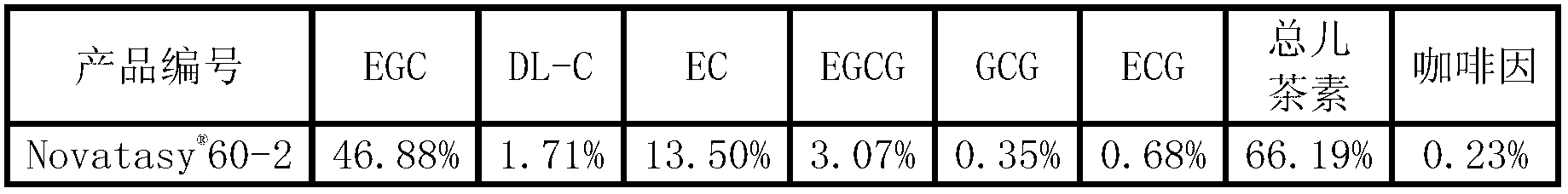

Embodiment 2

[0037] 1) Preparation 60

[0038] 500kg of tea leaves (GBT 14456.1-2008) were fed at 35°C with deionized water, the ratio of material to water was 1:40, and fed in a continuous countercurrent extractor at a feeding speed of 120kg per hour. Collect all the tea soup, filter it through stainless steel wire mesh and fine filter (WTL-cartridge filter), cool the filtered tea soup to 40°C and transfer it to the reverse osmosis concentration equipment, start the equipment, adjust the pressure at ≤11MP, and maintain the temperature Run at 40°C to concentrate the tea soup to 3Brix; adjust the pH of the tea soup to 4, add 9kg of tannase (2.5×10 4 U), and then start the reverse osmosis concentration equipment to adjust the pressure at 9MP and keep the temperature at 40°C for 3 hours, while satisfying the concentrated tea soup to reach 8Brix. After enzymatic hydrolysis and concentration, the tea soup is extracted with butanone-2 in a countercurrent extraction equipment at 40°C. The numb...

Embodiment 3

[0045] 1) Preparation 60

[0046] Throw 500kg of tea leaves (GBT 14456.1-2008) at 35°C with deionized water, the ratio of material to water is 1:50, and feed at a rate of 120kg per hour in a continuous countercurrent extractor until the feeding is completed. Collect the tea soup and filter it through a stainless steel wire mesh and a fine filter, cool the filtered tea soup to 40°C and transfer it to a reverse osmosis concentration equipment, adjust the pH of the tea soup to 4, and add 4.6kg of tannase (2.5×10 4 U), start the reverse osmosis concentration equipment to adjust the pressure to 8MP and keep the temperature at 40°C for 6 hours, while satisfying the concentrated tea soup to reach 5Brix. The concentrated and enzymatically hydrolyzed tea soup is extracted with ethyl acetate in a countercurrent extractor with a plate number of 30, and the ratio of the amount of ethyl acetate to the concentrated tea soup is 2.5:1. Concentrate the extracted ethyl acetate solution in va...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap